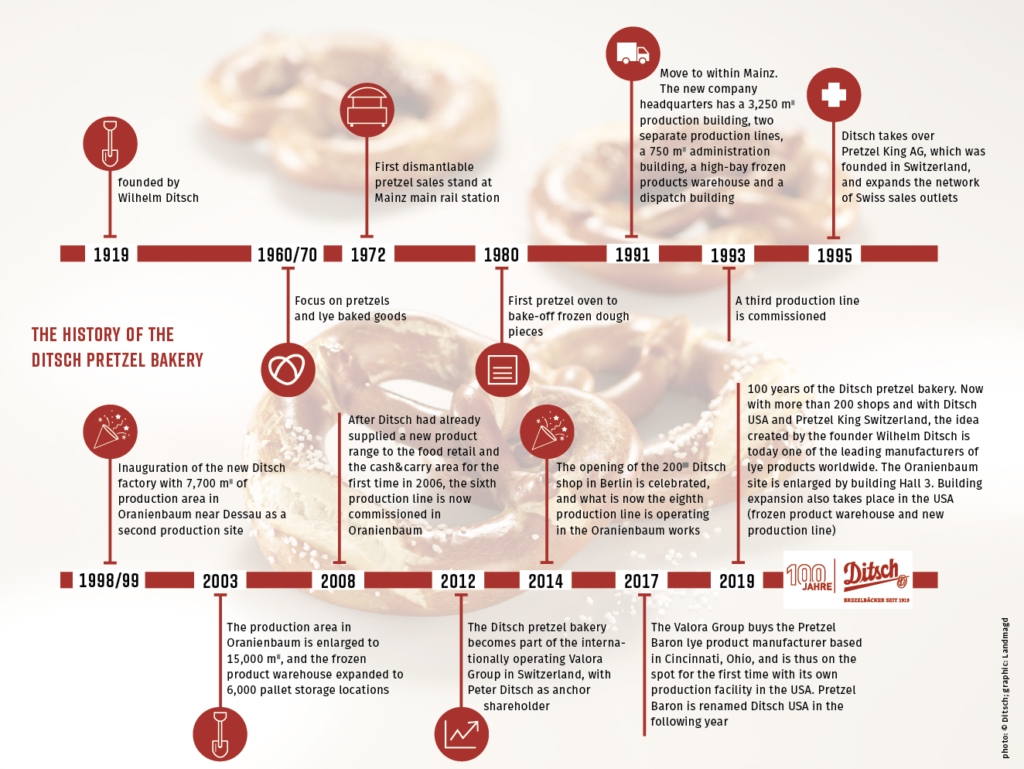

Ditsch has belonged to the Swiss Valora Group since 2012, and specializes in producing lye baked goods. The company invested around EUR 40 million at the Oranienbaum location.

Ditsch has belonged to the Swiss Valora Group since 2012, and is a lye baked goods specialist. For this, Ditsch operates around 200 sales outlets in Germany at highly frequented locations such as rail stations. With production factories in Mainz and Oranienbaum, and in Cincinnati, USA, the company is among the world’s leading suppliers of lye baked products. The very varied range of products offered includes pizza snacks and croissant specialties, in addition to the premium range of frozen lye baked goods.

In addition to producing for Ditsch sales outlets and Pretzel King shops, the company has very successfully supplied baked goods to large consumers since 1998, e.g. bakeries, hotels, restaurants, catering companies, filling stations and the food retail.

An extensive product range

In Germany, more than 700 employees currently produce over 600 million products/year in the Mainz and Oranienbaum factories. In 2017, Ditsch also expanded to Cincinnati in the USA, where approx. 30 employees make baked goods for the North American market on two production lines. The picture is rounded off with a production line in Emmenbrücke in Switzerland, where around 30 employees also produce lye baked goods.

Ditsch’s broadly-based product range extends from pre-proofed, frozen dough pieces to ready-baked, frozen products. The company is certified in accordance with IFS and BRC, and thus fulfills strictly-defined quality and safety standards. The company is also represented at national and international trade fairs such as Internorga, Südback, iba, Anuga or Sial. Ditsch exports its products to 28 countries worldwide.

Ditsch operates sales outlets at highly frequented locations such as rail stations

Valora Group

Around 15,000 employees are involved in the Swiss Valora Group’s network every day. Valora has more than 2,700 small-area sales outlets located at highly frequented sites in Switzerland, Germany, Austria, Luxemburg and the Netherlands. The company also owns k kiosk, Pretzel King, BackWerk, Ditsch, Press & Books, avec, Caffè Spettacolo and its own brand ok. – together with a steadily growing product range of digital services. Thanks to Ditsch, among other things, Valora has developed into one of the leading lye baked products manufacturers worldwide, and in the baked goods area it benefits from a strongly integrated value-added chain extending from lye baked goods production to sales to intermediaries (B2B) or in the form of the operation of takeaway concepts (B2C).

Exterior view of the production facility in Oranienbaum/Germany

Pretzels are produced on the new production line

Expansion at Oranienbaum

Around 230 staff work at the company’s headquarters in Mainz-Hechtsheim, where there is a production facility, an administration building, a high-bay frozen products warehouse and a dispatch building. The second location is in Oranienbaum, where around 500 employees have produced dough pieces and other baked goods since 1999. With a floor area of around 40,000 m2, the location has been continuously enlarged. As recently as 2019, the company invested around EUR 40 million in a new building and two new production lines, designed to expand capacity by around 15% and to create a total of approx. 100 new jobs.

More than a million baked products are manufactured at the Ditsch production facility in Oranienbaum every day. To make this possible, the operation runs 24 hours/day. In this respect, works manager Matthias Hartung relies on state-of-the-art technology and robots to produce frozen pretzels, for example. The production process demands a lot of know-how. The dough piece must not be too soft when being lye-dipped, and its shape must remain stable. The surfaces of the dough pieces are slightly dried out to ensure that the lye cannot penetrate too deeply, and the dough pieces must become firm before being lye-dipped. After this, the baked products are coated with a 3 – 4% soda lye solution for a few seconds and baked for 12 – 15 minutes. A lot of experience is needed to achieve the typical brown baked product color. As works manager Matthias Hartung explains: “For us, the marked contrast between the pale bloom and the chestnut-colored crust is a mark of quality.”

Round the clock

Lye bread rolls and lye sticks as well as pizzas, croissants (filled and unfilled) and molded cookies are also produced in Oranienbaum, in addition to Ditsch pretzels. Depending on orders and customers’ requirements, the lines must be reorganized every day, and the machines adjusted and recipes adapted. This needs very precise planning to ensure the machines can be operated as efficiently as possible. Therefore, it is also important to works manager Matthias Hartung that the employees work well together. He insists on flat hierarchies. His staff also regularly undergo further training. As works manager Hartung explains: “We systematically give our employees further training, which includes internal and external training courses. On the one hand, we want to remain an attractive employer and retain our employees’ loyalty, while on the other it also allows us to offer our staff a variety of career opportunities.”

The production facility at the Oranienbaum site operates 24/7, and plant capacity occupation is high, which also explains the investment in the new building with two production lines and a high-bay frozen product warehouse. The company is delighted with a steadily increasing demand for lye baked products, and the order books are full. Ditsch wants to remain Germany’s lye champion through constant investment in new technology, as well as in staff training and further education. The company also wants to achieve further growth