New York is the capital of trends, whether it’s lifestyle, fashion or food. Being successful and actually remaining there is a challenge, even for bakeries. Here we look at the story of Hudson Bread and how they made it in New York and still today remain on top.

A quarter of a century ago, Mariusz Kolodziej founded the Hudson Bread bakery just outside of the New York City border in North Bergen, NJ. After studying law and administration at the Naval Academy of his native Poland, he emigrated at the age of 24 to New York and initially worked in the real estate sector. But his dream of having his own company kept pulling at his heartstrings and a market analysis finally provided the perfect idea. Supported by bakery specialist Ray Million, Kolodziej founded a European-style specialty bakery, which was adapted to the taste profile of New York consumers and the needs of the hospitality scene. New Yorkers had been demanding this type of bakery for more than a decade and were ready to pay for it.

Mariusz Kolodziej says that the market has changed,” The fine dining establishments do not treat bread as an integral part of the dining experience as they did years ago. They look for price; quality isn’t as important to them as it once was. Restaurateurs view bread as losing an appetizer, which could be worth $12. I really don’t know when they will put bread back on the à la carte menu and charge for it, so that great breads can have their day again on fine dining tables.”

For Hudson Bread, this was not the only challenge. There was nowhere in the world where the trend towards “food-to-go” was more noticeable than in the Big Apple and there is

nowhere that has faster changes in nutrition trends.

Whether it’s a thermal oil, flue gas, deck or wagon oven, with or without a loading unit – when it comes to baking, Hudson Bread relies on MIWE technology

Kolodziej: “This leads us to think about the category that bread has grown most in and I would say it’s the food service area: caterers, cafes, mid-priced sandwich joints – these form a strong market. The customer’s buying pattern changes with each new trend and media blitzed information overload. It’s crazy to think about how peoples’ minds have been shaped: they will eat a wrap and think they have only taken in a few calories, but in reality the number of calories is close to the same as quality artisan products, except that these products are not produced with preservatives, shelf-life extenders, mold inhibitors and high sugar content. Marketing I guess?”

Hudson Bread has responded to the evolution of market needs and demands and continually evolved, changing processes and expanding capacities based on market reviews and trends. But one thing remains and has long since become a hallmark of Hudson Bread, the aroma of sourdough. 3 natural starters are used on a daily basis, white, wheat and rye along with Poolish and in some cases Biga. Core products are specialties such as sourdough country loaves with 4.5 kg loaves sold sliced.

By contrast, a frozen range called “Frozen Artisan” is compar-

atively young. Kolodziej: “The Frozen Artisan range has been in production for a year having started late 2018, early 2019. We wanted to offer our products in a different part of the food service industry and recognised that our products were missing as frozen offerings and so we developed our products to have all the great taste for this market.

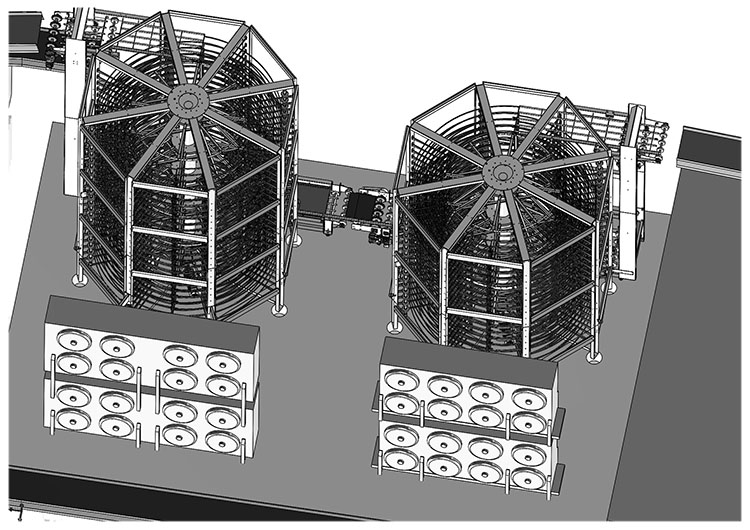

A complex network for thermal processes

To achieve maximum flexibility, Hudson Bread invested in a complex technical network consisting of proofers, ovens, and spiral cooling and freezing from MIWE, the German machine and oven builder. The network’s task is to provide and maintain product-specific process parameters such as time, temperature and air humidity for each product in the wide range of products, even when quantities fluctuate. This network begins with MIWE GV proofing retarders and MIWE GUV proofing interrupters for long-time dough methods.

Baking takes place in three MIWE ideal deck ovens (18 decks in total, each with a baking area of 180 x 200 cm), two thermal oil heated MIWE thermo-express deck ovens (18 decks in total, each with a baking area of 200 x 240 cm) and four MIWE thermo-static thermal oil heated wagon ovens (each for three wagons). Both types of deck oven are fed fully automatically by the MIWE athlet loading unit, which picks up dough pieces from peel boards. After baking, products from all three types of oven can either be brought to the dispatch area, or fed directly into the spiral cooler or spiral freezer via conveyor belts (in the case of the deck ovens: this takes place fully automatically; for the wagon ovens: products need to be placed onto the belt by hand).

Because Hudson Bread has also supplied frozen products all over the East Coast, the South to Florida and even the Midwest since 2018, a MIWE freezer plant was integrated into the existing concept. A spiral cooler and a spiral shock-freezer are available to cool and shock-freeze products after the baking process. Per hour, these can shock-freeze up to 810 kg of breads weighing up to 1,600 grams from +80°C down to a core temperature of at least -10°C within approx. 190 minutes. A special air guidance system in conjunction with controlled rotation speed fans in the shock-freezer spirals ensure that the products are frozen efficiently, uniformly and gently.

The advantage of the network, whose loading and transport solutions are also from MIWE, is the great flexibility with which it can adjust to the daily fluctuations in quantities on the one hand and the varying time requirements on the other. This is made possible not least by the uniform control architecture of all the plant components, which eases both its operation and its maintenance effort.

Ten years ago, 15 tons of dough was processed on a daily basis, seven days a week. Today, it’s 25 tons and Hudson Bread is now shipping its products all over the East Coast, south to Florida, and even to the Midwest. Here the deep-frozen brand is well represented and growth rates are encouraging.

Last but not least, substantial investments were required in production, as Kolodziej’s description of current production technology shows. “Ingredient handling is taken care of with with HB-Technik equipment which is used for liquids, preferments and dry ingredients. All scaling is automated and monitored with ingredient lot tracking. Mixing is carried out with DW240 Koenig Mixers twin ax. The process makeup used is Koenig equipment for Sheet and Cut Lines, (Menes), Koenig Roll Lines and Bun Lines, and Koenig Ceres Dividers for gravity feed dough portioning. At this moment we are working on two more lines for Artisan Frozen to meet customer demands. Our dough bulk ferments depending on the product and can take from 45 minutes to 3 hours before make up. Our bakery make up room is temperature controlled at 75 °F degrees with low CFM fans so as not to create drafting in the winter and it is glycol chilled in the summer to maintain approximately the same temp. The proofing room is quite small based on our volume, but we work in cooler temperatures for developing our flavor profiles. The controlled climate rooms are all by MIWE as well as the thermal oil ovens and ideal ovens. We prefer the consistent bake of thermal oil ovens and are planning a large earth stone thermal oil traveling oven for specific items.

For dough preparation, Ray Million, head of production, uses a twin twist mixer from Austrian manufacturer König

Ceres Menes Bun line – used for makeup when products are not made by hand

The freezing process has two stages. The first stage takes the product from the oven

temperature of 195°F to 40°F in a short and controlled time. This prepares the product for the second stage, which is freezing. This second stage was designed by MIWE as a streamlined, efficient process that handles the product with the proper parameters to ensure a quality freeze without drying the product out before packaging. If a product stays too long in a freezer it is stripped of moisture, damaging the product. So this process allows us to bring temperatures down to a desired point with a dwell time that supports product integrity. The process is supported by equipment from Czech company Liberecke strojirny for spirals and conveyors. The frozen products are then packed in our Niverplast cold room.”

There was also additional investment in the IT department. “The entire network system was upgraded with all systems software assembled by our in-house IT and Engineering department. A NYU graduate who was sponsored by our foundation that offers students an opportunity to work and obtain an education through Hudson Bread headed up this section. In this way, we are able to work with young minds with a different take on systems infrastructure.”

This year Hudson Bread is celebrating its 25th anniversary. It is testament to the Polish student, who has become a New York entrepreneur, relishing challenges and knowing that changes are a matter of course. Kolodziej, “We are always moving forwards, that’s what we do! However, during all of this, we cling tightly on to our core values and our mission to make bread that everyone would be proud to have their family eat, especially their children. This is because bread is a good thing, no matter what new research comes out to disprove that. Just as long as it’s wholesome bread made in true craftsman tradition. Just in moderation though!”

Hudson Bread, naturally cold proofed – daily production is still 12 hours out from bake and held at varying lower temperature points from 42 to 58-60 °F depending on formulation and desired product response