The Tecnopool Group, at one time mainly a conveyor belt specialist, is increasingly making a name for itself as a process technology supplier.

Doing one thing but not giving up the other – that’s how the development of the Italian mechanical engineer Tecnopool in San Giorgio in Bosco near Padua could be described.

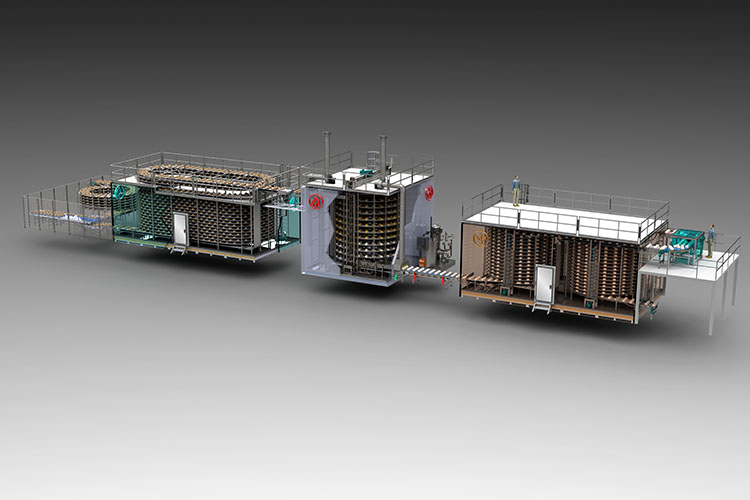

Tecnopool is still regarded as a specialist in a wide variety of steel rod belts for product transport. For the past two years, however, Tecnopool has expanded its field of activity and built a thermo-oil-heated spiral oven in which hot oil circulates in pipes under the levels of the spiral. Due to the way the spirals are built, the pipes run under one level and above the next. This allows the products being baked to receive radiant heat from both. Whether the oven has a circular or oval construction, and whether the belt entry and exit are at the top or the bottom, is decided by the customer, and so are the oven’s height and thus the number of spiral levels. To achieve a specific time/heat profile for a product, the oven can be divided into temperature zones with separate oil circulations. If required, convection heat is provided by a heat-exchanger in the center of the oven, supplied with hot oil and with a blower.

Depending on the need and the customer’s requirement, each oven has its own heating plant, but central oil heaters are also an option. There is a choice between various steel rod belts to convey the items being baked, depending on whether baking is to take place directly on the belt, on trays or in pan clusters. The spiral oven’s possible performance spectrum is broad. Plants with a capacity of 500 kg/hour for gluten-free products, and toast-bread plants with an hourly capacity of up to 4 tons have been built up to now.

Thus the oven builds on conveyor belt technology specific to Tecnopool, which is employed mainly in the global baked products industry where up to now as a rule it has been used in proofing and freezing plants or deep freeze. The aspect which makes Tecnopool’s belts rather special is that the drives are installed in an easily accessible position and do not need to be lubricated. In addition, they run really quietly and even in reverse if necessary, which also allows the plants to be used as buffer storage.

Spiral ovens also bake pan clusters

The secret is in the connections between the steel rods and what drives them forwards. The rods are welded to steel elements whose ends are attached to sliding elements that in turn run on rails. The shape of the guide track prevents the belts from jumping out of the guide. They are driven forwards by wheels that engage in the chain guide from the outside, one spiral and one drive wheel on a separate drive shaft for each level. This ensures that each level is pulled uniformly, and excludes jerky movements. The drive wheels are the only things that need to be serviced. Whether one or more motors is/are used depends on the height of the spiral tower.

This kind of drive technology frees customers and the designers from the need to build circular spirals in every case. Ovals are equally possible, as are systems in which the belt spirals upwards then moves downwards again inside the upward-moving first spiral, so the entry and exit are both located at the ends of the spiral near the floor.

The spiral oven is not the only thing that set in motion Tecnopool’s transformation to a process technology supplier. The company, still majority-owned by the founding family Lago, took over the Slovenian bakery machine builder Gostol-Gopan D.o.o. Tecnofryer S.L.U. in Valencia, Spain, which produces industrial fat frying plants, has already belonged to the company for some time.

TECNOPOOL S.p.A.

www.tecnopool.it Hall B6, Stand 230