The use of pomace in bread and bakery products has so far only been used in a few bakeries. However, the processing of non-dried vegetable pomace has several advantages that offer promising development potential.

In the production of fruit and vegetable juice, not inconsiderable amounts of pressing residues are produced, which are mostly used as animal feed and in fertilizers. The further processing into food and semi-luxury goods (e.g. spirits) is used particularly for grape and apple pomace. Well-known pomace spirits are the Italian Grappa and the French Marc. However, the quantities processed are small compared to the amount of pomace produced. Grape and apple pomace can also be used to produce fruit vinegars, which are suitable for salads and spicy dishes. Fruit and vegetable pomace is also partly used as a raw material for the extraction of fibers and pectin (citrus, beet and apple pomace).

Pomace is predominantly the solid residue left after pressing the juice of fruit, vegetables or plant components such as apples, grapes, carrots, tomatoes, etc.

Carrot pomace

Beetroot pomace

Carrot pomace sourdough

Untreated pomace is rich in dietary fiber and fruit secondary plant compounds such as flavonoids, carotenoids and complex polyphenols, which are excellent as value-adding additives in bread and baked goods. In addition to the positive effects of these secondary plant substances (including antioxidant effects), the natural matrix in which the ingredients are found must be emphasized in comparison to isolated ingredients. Here, however, the effects on the sensory system must also be considered. A further advantage is the low energy input compared to fiber production, which requires a high-energy input for drying the pomace. In addition, the fibers obtained by the drying process often also have an unpleasant side odor and/or taste, and so can only be used in food to a limited extent. Furthermore, the use of native pomace in bread and bakery products does not produce any other residues, as is the case when processing into spirits and vinegar. The fruit and vegetable pomace is thus fully utilized and can increase the overall nutritional value of processed foods.

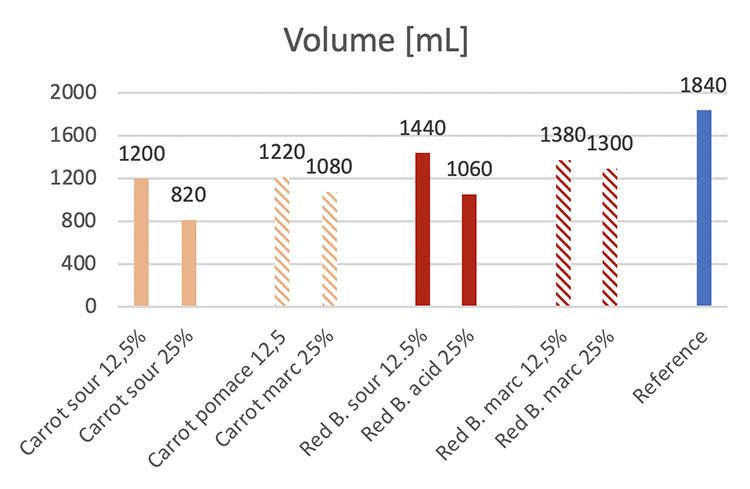

Diagram 1: Comparison of the determined bread volumes

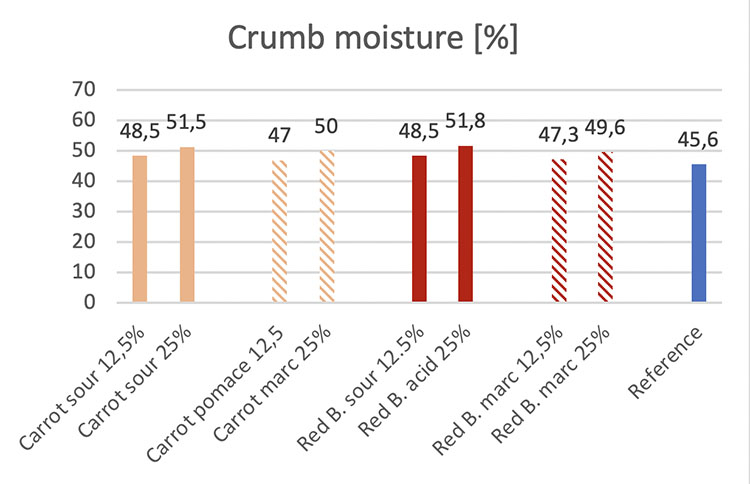

Diagram 2: Comparison of the determined crumb moisture

In order to further use the valuable pomace from juice production in the sense of a low-waste recycling economy, the Institute for Food and Environmental Research (ILU) is in active exchange with a regional fruit and vegetable juice producer. In cooperation with a bakery in Berlin/Germany, the first baking trials for the use of fruit and vegetable pomace have been carried out. For this purpose, two pomace varieties (Fig. 1 and 2) were processed on the basis of a traditional wheat mixed bread recipe. The pomace was added in two bakery technological procedures. In one scenario, pomace was added directly to the dough, whereby the pomace was briefly undercut at the end of the kneading process. And in another scenario, the pomace was fermented in combination with rye flour (Fig. 3) and further processed as sourdough in the main dough. In both processes, 12.5% and 25% of the total flour quantity was added to the pomace.

The pomace variants used had different effects on the bread volume. Basically, the addition of pomace reduced the bread volume and with increasing proportions, this reduction increased. It turned out that the directly added pomace had a slightly better effect on the volume of the bread and that the use of pomace sourdough was more likely to be disadvantageous for the bread volume when a higher quantity was added. In comparison with carrot pomace, the processing of beet pomace showed a smaller reduction of the bread volume (diagram 1).

As illustrated in Figure 4, a lower volume does not necessarily mean a reduction in bread quality. Even breads made with 25% added pomace can have a loosened crumb structure with chewy qualities.

Bread cross sections from carrot pomace baking test series top left: wheat mixed bread addition carrot-sour dough 25 %

top right: wheat mixed bread addition of carrot pomace 25 %

bottom left: Reference sample wheat mixed bread without added pomace

bottom right: Wheat mixed bread addition of carrot pomace 12.5 %

*The percentages refer to the total quantity of flour.

Wheat mixed bread – beet pomace as a direct addition (25 %)

Mixed wheat bread – addition of beet as sourdough (25 %)

As expected, a significant increase in crumb moisture is generated by the addition of pomace rich in fibers. By using sourdough based on pomace, the crumb moisture content in particular can be increased by a good 6 percentage points (diagram 2).

The influence on the intensity of smell and taste was only slightly pronounced for both pomaces used. At an added quantity of 12.5 %, the sensory test panel did not detect any specific change in aroma. At an addition of 25 %, the ‘earthy’ aroma typical of the raw material was perceived in bread with beet pomace. A slight ‘fruity-sweet’, carrot-like note was detected in bread with carrot pomace. The processing of the pomace as sourdough is recommended due to the not always popular earthy smell, which is typical for beet pomace.

With regard to the coloration in the end product, a distinction must be made between the respective types of pomace used. Carrot pomace caused a yellow-

orange crumb color in both process variants (direct addition vs. sourdough). As expected, the color intensity increased with higher pomace addition. When processing beet pomace, the typical red-violet coloration was observed when directly added (Fig. 5). In the sourdough variant, the color changed from reddish-purple to yellowish-orange, due to the long fermentation time (16 hours) and there was a change in pH value due to the acidic range (pH 3.5). This effect is due to the plant dyes contained in the beet, which change color depending on the pH value. In contrast to the relatively stable carotenoids of carrot pomace, the anthocyanins and betalaines present in beet change color when exposed to low pH values for a long period of time. This is comparable to red cabbage, which is reddish-purple in color when prepared with acid, and is perceptible as blue-violet cabbage at higher pH values. The breads produced here with beet sourdough had a greenish crumb color (Fig. 6).

In the joint project ‘NutriAct – Competence Cluster Nutrition Research Berlin-Potsdam’, scientists from the sub-project ‘New Products’ are pooling their know-how to develop tasty products with a composition that is suitable for the elderly and promotes health, such as pomace bread.

Conclusion

The processing of pomace into bread is an interesting and expandable alternative to conventional recycling. Besides the nutritional advantages, the large number of pomace variants offers the possibility of developing unique products for every bakery. By networking with local juice producers, the regional added value is additionally improved.

Author

Dipl.-Ing. Alexander Voß, Institute for Food and Environmental Research (ILU), Bergholz-Rehbrücke near Berlin/Germany