As preparations are in full swing for interpack 2023, exhibitors share solutions they are focusing on, information about new technologies that bakers can see at the show, as well as their views on the trade show and the industry.

IPCO

Hall 3 D20

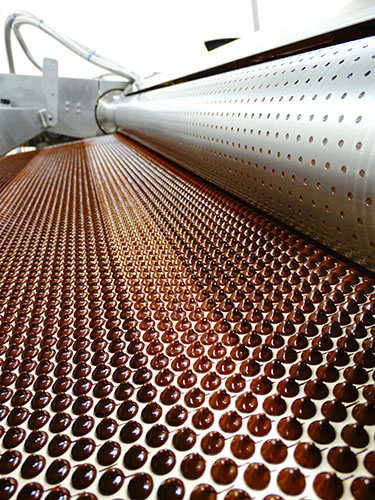

IPCO highlights chocolate forming systems at interpack, designed for the production of industrial ingredients – chips, chunks, drops and blocks – and decorative products such as shavings, rolls, pencils, blossoms, etc.

“These have applications across the bakery industry, with ingredient products used in everything from cookies and cakes to brownies and muffins, and decorative products used to add value to cakes, pastisserie and other premium products,” IPCO details.

The main highlight will be its flagship Rotoform system, with a fully operational unit at the stand. Rotoform is a rotary drop depositor that produces chips of highly uniform size and shape and this is the foundation on which all of IPCO’s high-capacity systems are built. “Chips are free-flowing for easy handling, storage and dosing. The system is also extremely versatile in that chips of different sizes – from 30,000 to 300 pcs/kg – can be produced by simply changing the shell,” IPCO explains.

Among the company’s latest solutions is its piston depositor that uses a D-motion to deliver chocolate or compound directly onto a moving belt.

This is the first time IPCO joins interpack with its new brand name. “Six years ago we were still Sandvik Process Systems so, if any visitors are unfamiliar with the IPCO name, it will be an opportunity to reintroduce ourselves and help them make the connection!”

© IPCO

The article is part of an extended feature, which was originally published in [BBI 2 – 2023]. Read the full article in the magazine: