By Yogesh Sharma, Michael Metzenmacher, Ulrike Vogt, Thekla Alpers, Dominik Geier, Thomas Becker

Chair of Brewing and Beverage Technology, Technical University of Munich, Germany

Targeted cleaning can be adapted to the status of the pipelines for efficient operations.

The progressive automation of bakery lines requires the provision of cleaning concepts that can be monitored and controlled using inline methods. While transporting individual dough ingredients, pumpable components (such as pre-ferments and sourdoughs), along with soaker doughs, scaled doughs, batters, and final doughs, deposits accumulate in the pipelines, leading to fouling. With increasing process duration, fouling can detach from the wall and pass into the product. This can lead to a sensory and qualitative reduction in product quality and endanger product safety. Cost-intensive, carbon-based coatings for product-contacting surfaces are currently being investigated to reduce the formation of deposits in pipelines. However, sufficient prevention of deposits is not possible with this approach. Therefore, the deposits must be removed by cleaning-in-place (CIP) programs at the latest after the end of the process.

“The attenuation of the ultrasonic signal can be used as a parameter for monitoring the cleaning process.”

To ensure consistently high product quality and uninterrupted production, intensive cleaning programs must be carried out due to the lack of inline-capable methods to assess the current level of fouling in the system to be cleaned or to evaluate the achieved cleaning success. These cleaning programs are oversized in duration and intensity to achieve thorough cleaning, even in the presence of heavy fouling. An inline cleaning monitoring, on the other hand, would enable targeted cleaning adapted to the respective fouling level while simultaneously improving product quality and safety, shortening system downtimes, and saving resources.

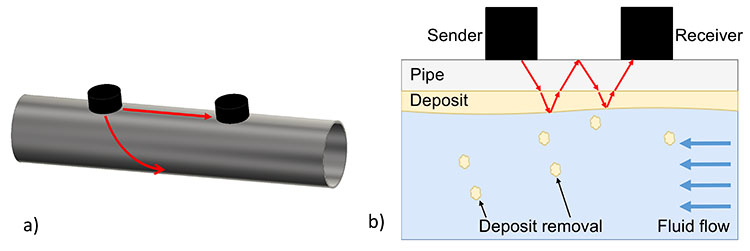

Figure 1: a) Design of an ultrasonic system and propagation of surface waves between sender and receiver. b) Schematic representation of the interactions of surface waves with adhering deposits on the inside of a pipe

Detection of deposits in pipelines with ultrasound

An ultrasonic sensor system has been developed for non-invasive detection of deposits, see Figure 1. An ultrasonic sender emits waves along the pipeline while a receiver records the propagating waves. Ultrasonic waves can travel in the pipeline in straight and spiral paths (Figure 1a). The ultrasonic waves also propagate on the inside of the pipe and interact directly with the fouling adhering to the inside of the pipe (Figure 1b). In a clean pipe, the amplitude and energy of the ultrasonic waves decrease with time and distance between sender and receiver due to the attenuation by steel. The reduction in the amplitude of an ultrasonic wave is referred to as attenuation. In the presence of deposits, the attenuation of the ultrasonic waves increases, further reducing the amplitude and energy of the ultrasonic waves detected at the receiver. This principle can be used to detect varying degrees of fouling in the pipeline.

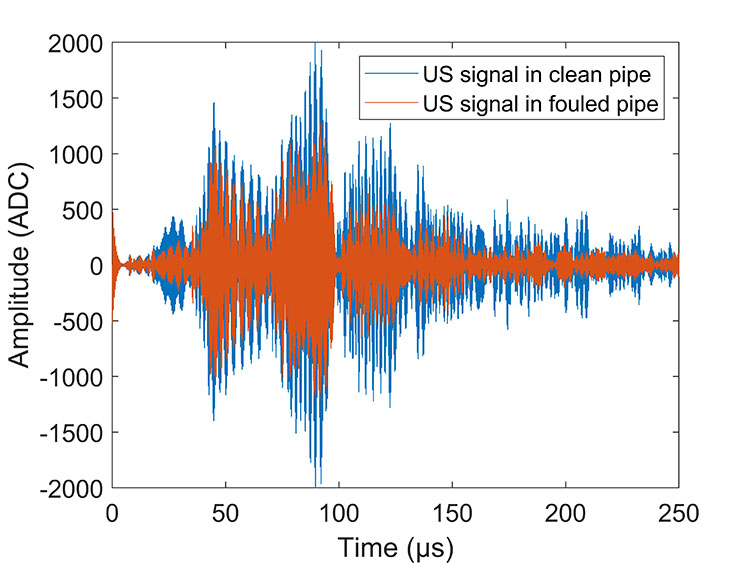

Ultrasonic sensors with a resonance frequency of 2 MHz were used as sender and receiver, and the sampling rate was 50 MHz, thus providing a high temporal resolution in the ultrasonic signals. The received ultrasonic signals were then filtered using a Butterworth bandpass filter. As a model deposit, scald dough with a dough yield ratio of 250 (DY 250) was prepared by mixing whole wheat flour and tap water heated to 100 °C and applied to the inside of the pipe. The comparison between the ultrasonic signals of a clean pipeline and a fouled pipeline is shown in Figure 2. The ultrasonic signal was significantly attenuated in the presence of deposits.

Figure 2: Ultrasonic signals of a clean pipeline and a pipeline with a defined deposit (scalded dough, DY 250)

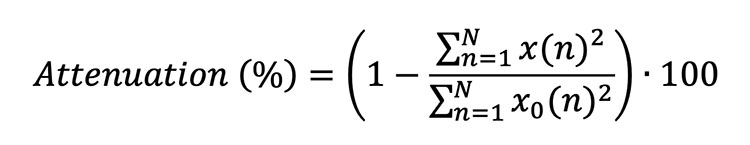

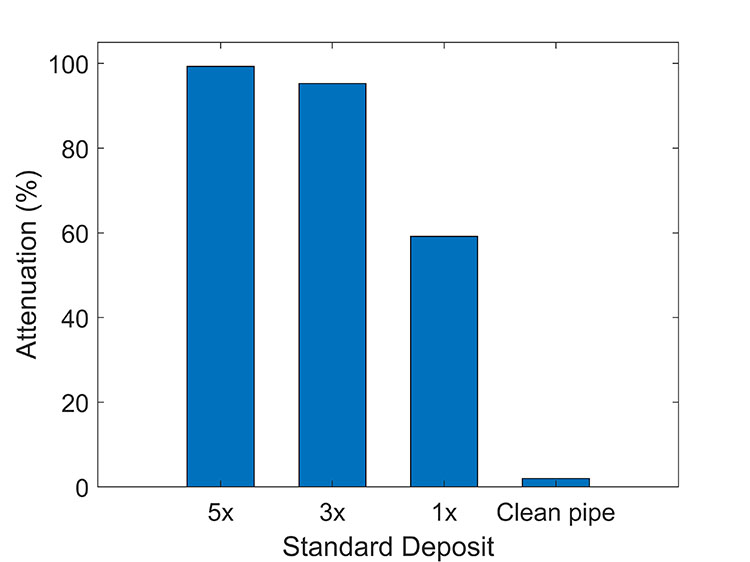

Different amounts of model deposits were applied to the pipe, and the change in the attenuation of the ultrasonic signals was investigated. A deposit of 3.5mg/cm2 on the pipe’s inner surface was defined as a standard deposit. The attenuation of the ultrasonic signals was calculated from the signal with the determined amplitude x and the amplitude of a clean pipe (X0):

Figure 3 shows the comparison between signal attenuation and the applied amount of fouling.

Figure 3: Comparison of deposit (standard deposit = 3.5 mg/cm2) and signal attenuation

Cleaning monitoring

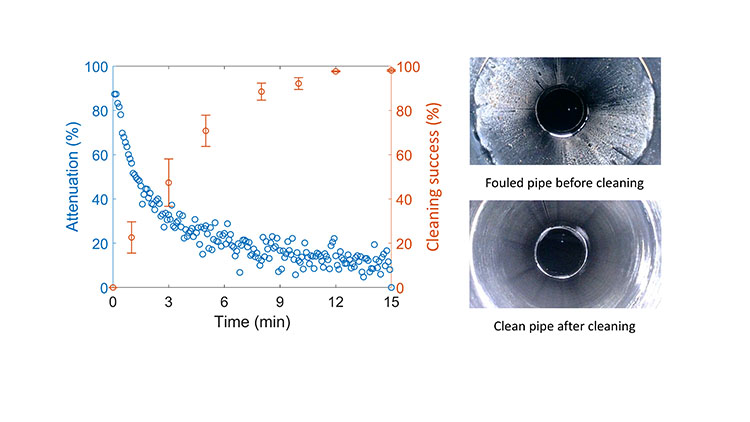

A CIP pilot plant was used to monitor cleaning, which allowed stepwise cleaning of the fouling in the pipeline until complete cleaning was achieved. Defined fouled pipelines (5mg/cm2 scald dough, DY 250) were connected to the CIP pilot plant for cleaning. The developed ultrasonic system was coupled to the pipeline, and an ultrasonic measurement was taken every five seconds. The amount of fouling in the pipe could only be determined before and after cleaning (by tare weight), as this required the pipe to be removed from the CIP pilot plant and weighed. Therefore, cleaning tests were performed with different cleaning times, thus varying the amount of deposits for different cleaning conditions before and after cleaning. Subsequently, the cleaning success was calculated for various cleaning times, as shown in Figure 4. The cleaning program continuously reduced the fouling in the pipeline. The visually determined fouling condition of the pipeline before and after cleaning is also shown in Figure 4. As expected, the attenuation of the ultrasonic signals decreased with the cleaning time, which is consistent with the previous results (see Figure 3). As the cleaning of the pipeline progresses, the signal attenuation continues to decrease.

Figure 4: Signal attenuation (blue) and cleaning success (orange) during cleaning of a pipeline with an initial deposit of 5 mg/cm2 scalded dough (DY 250). The initial and final conditions of the pipeline are shown on the right

The attenuation of the ultrasonic signal can be used as a parameter for monitoring the cleaning process. A decrease in signal attenuation indicates that fouling has been progressively removed over time. The attenuation plateau corresponds to the plateau of the actual cleaning level. Thus, ultrasonic attenuation can also indicate the end of cleaning. The ultrasonic system was also tested for cleaning other dough systems (e.g., sourdough). It showed comparable results, including the formation of an attenuation plateau, which indicated the end of the cleaning process.

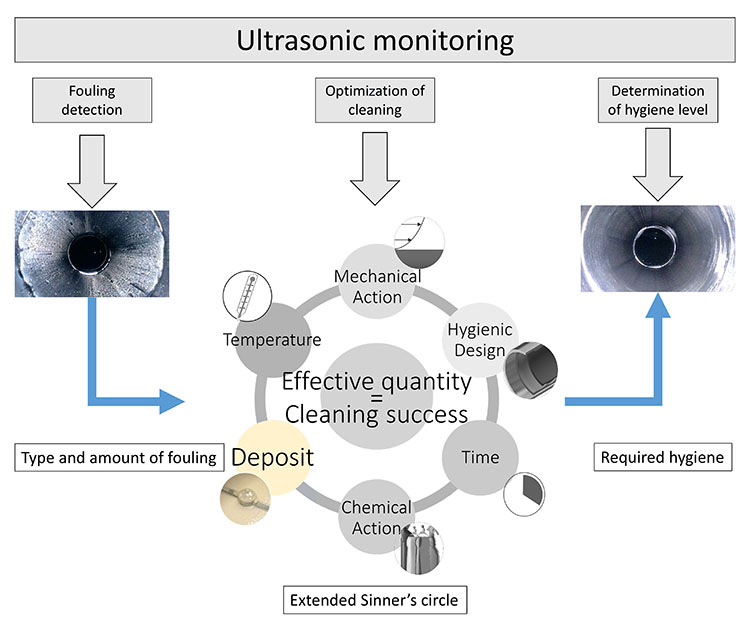

Figure 5: Optimization of CIP processes by ultrasonic monitoring before, during, and after cleaning

Optimization of CIP processes

In addition to the ‘classical‘ four parameters (temperature, mechanics, chemistry, and time), Sinner’s circle can be extended by two further parameters (deposits and hygienic design). Through the extended Sinner’s circle (Figure 5), the type and amount of fouling are introduced into the concept. To optimize cleaning, all parameters must be considered. The ultrasonic measurements presented here can be performed before, during and after cleaning to obtain information about the type and amount of deposits. By determining the initial amount of deposits with ultrasound, an optimal cleaning program (temperature, mechanical, chemical, and time) can be selected. Furthermore, ultrasound-based monitoring can track cleaning progress and adjust rigid cleaning times in CIP cleaning programs by identifying the cleaning end.

By monitoring pipeline cleaning with ultrasound, optimized cleaning programs can be developed that enable adaptive cleaning. Plant operators who rely on cost-efficient cleaning can benefit from this advanced technology, achieve optimized cleaning results, and simultaneously save resources.

Acknowledgment

This IGF Project of the FEI (AiF 18646 N) was supported within the program for promoting the Industrial Collective Research (IGF) of the Federal Ministry of Economic Affairs and Climate Action (BMWK), based on a resolution of the German Parliament.