Ishida Europe will showcase a comprehensive range of packaging equipment at interpack, highlighting automated solutions that support operational efficiency, product quality and food safety. The solutions are meant to address the challenges faced by the industry over the last three years, and support sustainability efforts. To celebrate its 130th anniversary this year, Ishida will bring 40 pieces of equipment to display at the trade fair, focusing on four areas: weighing technology, quality control solutions and ‘end-to-end’ packing line solutions.

“Ishida’s team of packaging industry experts have been working closely with many customers across the world to ensure that together we can overcome challenges and make our automation solutions the foundation of lasting competitive advantage,” said Steve Jones, Marketing Director of Ishida Europe. “Our international team will be at Interpack to discuss projects with visitors and provide solutions that are both flexible enough to overcome today’s challenges while ensuring businesses have a robust plan which considers the future.”

New product launches

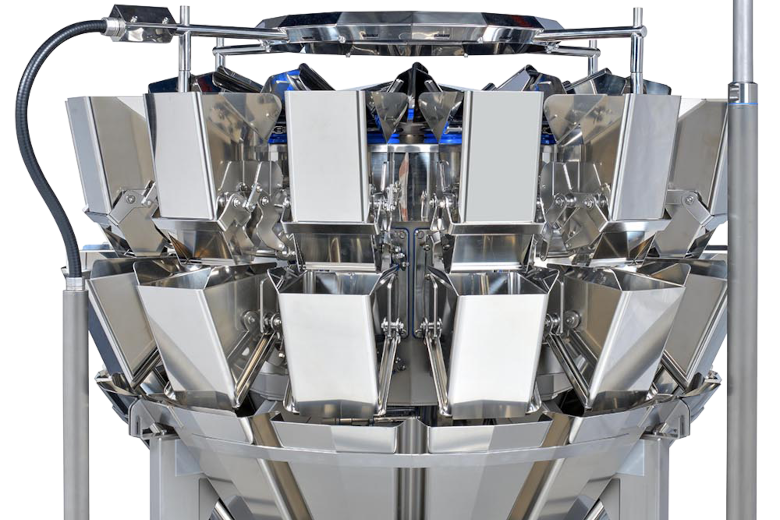

Each of the four areas of the stand will also feature a new Ishida development – the new CCW-AS multihead weigher, IX-PD X-ray inspection system, QX500 tray sealer, and a first look at the company’s new complete snacks packing line solution.

The Ishida CCW-AS is the company’s 11th generation of multihead weighers. It has been specifically designed to offer the best weighing performance, with significant energy reductions.

The Ishida IX-PD top-of-the-range X-ray inspection system incorporates new sensor and image processing technology. It can identify both low-density and very small-size foreign bodies.

The QX500 brings a 66% increase in cycle speed, a 44% reduction in weight, a 46% reduction in size and a 50% reduction in energy usage compared with previous tray sealer technology platforms.

A complete snacks packing line for pillow packs comprises an Ishida 14-head multihead weigher and Inspira rotary bagmaker, together with a new TSC-AS seal tester and new ACP Automatic Case Packer. The fully integrated snack food solution delivers a close-to-zero giveaway, close-to-zero film waste and greater than 99% OEE, Ishida highlights. The system can handle up to 200 bags per minute for extruded snacks.

Ishida will also demonstrate its market-leading “Sentinel” Industry 4.0 software that combines machine performance monitoring with comprehensive data capture and in-depth analysis. This allows preventative maintenance and effective planning of servicing.

In addition, the stand will feature a demonstration of Ishida’s Augmented Reality technology, which during the pandemic helped the company to service customer machines without needing to travel. Using google lens technology, Ishida engineers can guide customers remotely to help them troubleshoot and maintain optimum performance.

Photo: Ishida Europe