Key IBIE exhibitors share their latest developments and the innovations they bring to IBIE 2025. Here are some of the essential A-Z.

West Hall

3500/3801

AMF Bakery Systems

AMF Fusion will showcase the latest in horizontal batch mixing at booth #3801, unveiling the new, robust Open Frame Tilt Bowl Mixer (OFTBM) designed for strength, ease of cleaning, and improved accessibility. The portfolio of SNAX Sigma Arm Mixers, designed for snack foods, is also on display. AMF Fusion and AMF’s Bakery Intelligence team will also demonstrate the updated Dough Guardian+ vision technology, designed to help monitor the mixing process.

At booth #3500, AMF automation technologies take center stage, including new AMF Flex and AMF Tromp make-up technologies such as the AMF Tromp Target Glazer and the modular AMF Tromp Pizza Topping Line designed for precision sauce and topping placement.

AMF BakeTech and AMF Den Boer showcase the latest sustainable baking technologies, including the award-winning hybrid baking and hydrogen burner technologies, and the Sustainable Oven Service for more energy-efficient baking. AMF Convay will present its sanitary belt designs that can be used from mixer to marketplace applications. AMF Workhorse and the Bakery Intelligence team will demonstrate the new digital twin technology to support testing of new equipment and reducing installation time.

AMF will also arrange virtual tours of the new Puratos Industrial Pilot Bakery – powered by AMF, helping customers reduce operational disruption while accelerating innovation.

North Hall

6813

ANKO

ANKO is showcasing its SD-97W Automatic Encrusting Machine, with a focus on its application for producing energy balls, a trending product in the health and snack food category, popular in the US. Live demonstrations will show how the equipment can handle a wide variety of textures and inclusions, such as oats, chia seeds and nut butters.

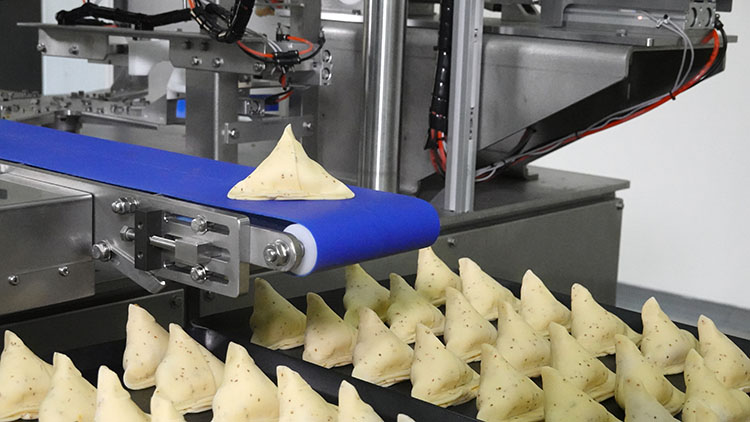

ANKO recently launched the world’s first machine capable of mass-producing Punjabi samosas in their traditional pyramid shape, with just two operators needed at the forming end, the company shares. The system features a fully in-house developed mechanism that sequentially folds the samosa pastry, stuffs the filling, and seals it automatically.

The company will also present new integrated food production lines for flatbread production. The complete system integration covers every stage, with tooling flexibility designed to support regional variations and recipe-specific adjustments.

North Hall

5010

Anton Paar/Brabender

The company will showcase the newly launched Brabender ExtensoGraph, a next-generation solution for dough extensibility and processing analysis, featuring an integrated PC with MetaBridge software. The machine is available as a compact unit or as modular components to fit various lab setups. “With innovations like ultrasonic-controlled humidity, automated test initiation, and environmental monitoring via the Climate Logger, the ExtensoGraph ensures high reproducibility and precision,” the company explains.

The stand will highlight the critical importance of flour and dough rheology for consistent, high-quality baked goods. “Anton Paar and Brabender, now united under the Anton Paar umbrella, offer the most comprehensive range of flour, dough, and starch analysis solutions available on the market today,” Anton Paar USA underlines. From grain milling and moisture content to dough rheology, gluten performance, starch gelatinization, and process integration, every critical step in the quality control and product development chain is covered.

West Hall

2101

Ashworth

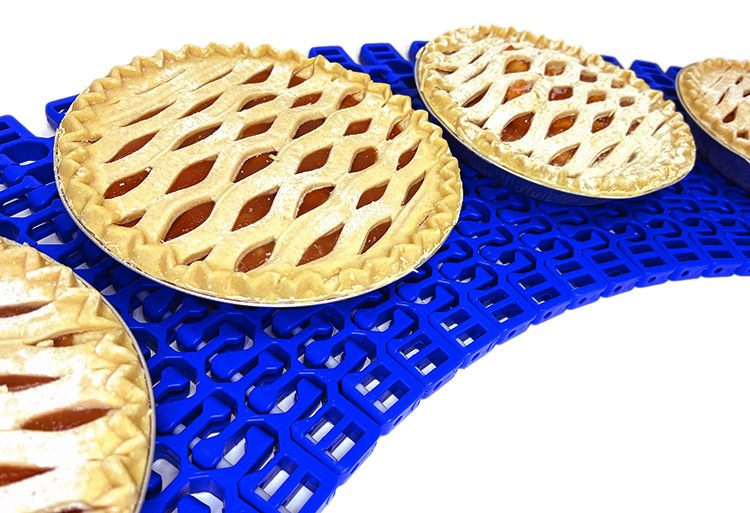

Ashworth introduces an expanded portfolio of plastic conveyor belt solutions, in addition to a new heavy-duty metal conveyor belt. New launches will be unveiled at the show, including a Heavy-Duty Small Radius Omni-Grid® 360 Weld. With the highest tension-rated belt in the small radius belt market (400 pounds), it is the first of its kind, Ashworth anticipates. “Combined with its patented zero-tension, 360 buttonless weld, it offers improved durability, additional strength, is easy to clean, and can increase belt life,” the company highlights.

The Ashworth EZ Splice® technology will also make its debut, offering the strength of metal with the simplicity of plastic belting – no welder required.

“As we continue to expand upon our plastic belt solutions and innovate our metal belt offerings, Ashworth Bros., Inc. offers a one-stop solution for all your conveyor belt and maintenance needs,” the company highlights.

West Hall

2125

Baker Perkins, a brand of Coperion

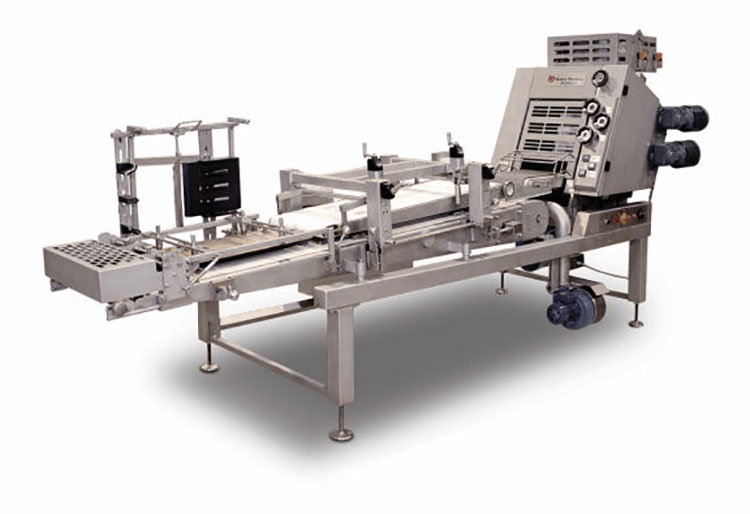

For the cookie industry, Coperion will showcase the full range of Baker Perkins Wirecuts and Rotary Moulders, including a new Frozen Dough Mini machine. These versatile machines can make a variety of products such as cookies, mini cookies, high-inclusion cookies, frozen dough cookies, bulk-packed dough, bars, and more.

Other Baker Perkins equipment on display will include the MultiTex4 Bread Moulder and Seeder, for bread production.

West Hall

2137

BAKON, a brand of Coperion

Alongside Unifiller technologies, Bakon solutions will be on display in the downstream zone of the Coperion booth, where the group’s brands will showcase their capabilities in baked goods. Bakon technologies include top-quality spraying, decorating and ultrasonic cutting machines for all bakery applications.

North Hall

8049

BENEO

BENEO will bring a wide variety of its natural and non-GMO functional ingredients to IBIE. There will be a special focus on Orafti®β-Fit, a 100% wholegrain, high fiber barley flour, which is an innovation in heart health as it provides an industry-leading source of beta-glucan fiber, significantly higher than conventional cereal flours. This allows FDA-approved heart-health claims to be made on-pack, in a more cost-efficient way.

Also front and center is BENEO’s clean-label faba bean protein concentrate, popular for baked goods, cereals, and snacks, and its portfolio of rice ingredients (including protein, starches, and flours), for gluten-free specialties with excellent taste and texture. “Combining faba bean and rice protein allows the achievement of a complete essential amino acids profile,” BENEO explains.

North Hall

6132

West Hall

2625

Bundy Baking Solutions

At IBIE, Bundy Baking Solutions will highlight its extensive bakeware range and related solutions, highlighting its newest developments and case studies for ePAN®designs, non-PFAS formula coatings, Integra release agents, and the award-winning AccuSpray Pan Oiler. “At Bundy Baking Solutions, we’re constantly innovating to keep up with the demands of modern baking operations. From smarter pans and advanced coatings to expert release agent formulas and refurbishment services, our products are always designed with our customer’s bakery in mind and how we can deliver solutions that help them bake more efficiently,” the company shares. Sustainable baking solutions and new bakeware innovations will take center stage at the stand in Las Vegas. The Bundy family of companies encompasses the following brands, to name a few: American Pan, AccuSpray, Chicago Metallic, Pan Glo, and Synova.

West Hall

3825

Corbion

Corbion introduces Ultra Fresh Plus 100, a new clean-label, enzyme-based solution designed to simplify recipe formulation while maintaining product quality throughout the shelf life. “With this solution, bakers can replace conventional emulsifier solutions and maintain initial softness and sliceability,” Corbion explains. The ingredient specialist will also present an expanded natural mold inhibitor portfolio to provide more flexible options for formulators looking to scale with confidence. The company will also share trend insights on better-for-you innovation and the impact of GLP-1.

“Bakers are facing unprecedented headwinds and we are highlighting how our entire portfolio of freshness solutions, dough improvers and shelf life extension can help them evolve with the changing demand,” Corbion says.

West Hall

2400

Dawn Foods

At IBIE, Dawn Foods will highlight knowledge sharing. Its highly anticipated Global Trend Research will be presented, which analyzes shifts in the bakery landscape to identify opportunities for growth. Dawn Foods will share insights into its proprietary research and the four key trends it identified in a QuickBITE session held on September 14 on the Wholesale Bakers Stage 1 – West Hall (2:15 pm).

Ahead of this focused event, Dawn will highlight its insights during the IBIEducate learning day. On September 13, a knowledge-sharing seminar titled ‘From Oven to Opportunity: A Panel Discussion on the Future of Bakery Trends and Evolving Consumer Preference’ will be held. The panel will be moderated by Sarah Hickey and includes three panelists: Cathy Wisloski, Chef Melissa Trimmer and Erik Enyedy.

West Hall

1825

DIOSNA, a brand of Coperion

DIOSNA will showcase kneading and mixing machines for the baking industry, for both pre-dough and dough processing. DIOSNA will demonstrate their Automatic Guided Vehicle (AGV)-based transport solution specifically for batch mixing systems in bakeries of all sizes. This scalable solution streamlines dough handling for increased efficiency and profitability.

North Hall

5320

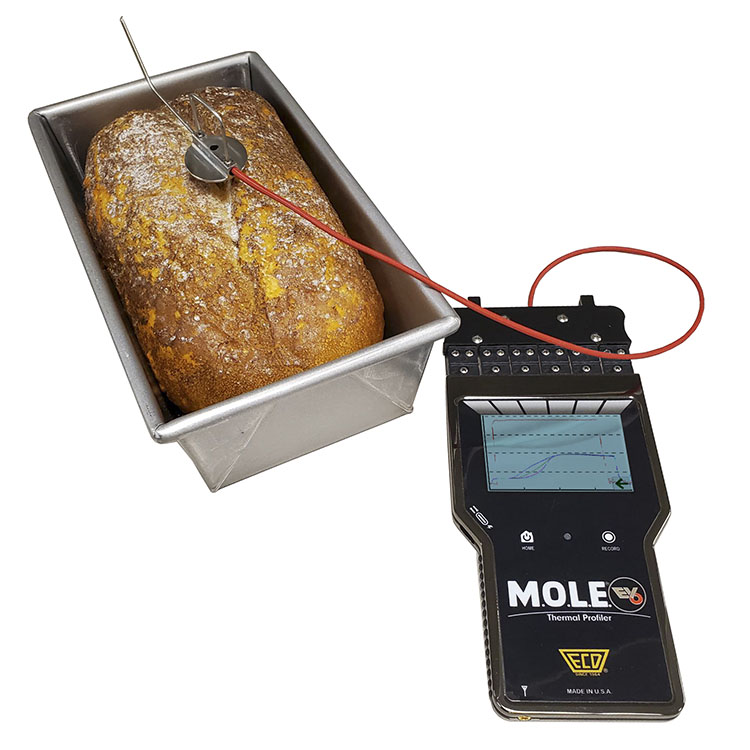

ECD BakeWatch

At IBIE, ECD will showcase its M.O.L.E.® EV6 six-channel touchscreen thermal profiler and the V-M.O.L.E.® 2 thermal profiler, along with its BreadOMETER®, CakeOMETER®, and OvenBALANCER™ sensors, designed for product and oven process control. These tools enable precise measurement of relative humidity in proofers, oven balancing within individual ovens or across multiple ovens in a facility, and more consistent temperature measurement for cakes, breads, cookies, and other baked goods. Visitors can also expect live, on-demand demonstrations of any of the process control tools at the stand.

In addition to ECD’s OvenBALANCER sensors for heat balancing inside and between ovens, the company will debut its new watertight thermal profiler barrier, the M-VP™. This sealed barrier protects the thermal profiler during immersion or in high-humidity processes. “The M-VP is designed to withstand the rigors of water immersion for boiling processes, as well as deep-frying in oil, allowing for precise measurement of product transformation within these challenging environments,” ECD explains.

West Hall

2901

FRITSCH

At IBIE, FRITSCH will highlight the new PROGRESSA pastry line, specially developed for retail bakers. It brings improved hygiene, easy handling, and high performance. “The line features a hygienic design throughout, including smooth surfaces, watertight covers on threaded connections, and rounded corners that prevent dirt buildup,” FRITSCH highlights. Maintenance and cleaning are also simplified, with a linear quick-release mechanism on the belt.

FRITSCH will also showcase the capabilities of the IMPRESSA series for high-output bread, croissant, and flatbread production, as well as the MULTITWIST for specialty-shaped doughs. Part of the MULTIVAC Group, FRITSCH will highlight its partnership with MULTIVAC for full-line solutions, from dough to distribution.

West Hall

325

Handtmann

Handtmann, Inc. is showcasing next-generation bakery solutions designed to help producers meet current market demands and production goals with precision, consistency and scalable automation.

Featured technologies include fast, continuous, multi-lane dough dividing and co-extrusion systems that deliver accurate portioning with minimal waste, along with flexible depositing solutions. These technologies are designed for easy product and format flexibility, helping bakeries expand offerings and achieve consistent quality at high production volumes, without the complexity of overhauling their processes. “Our technologies cover a broad range of bakery applications from pocket and filled products to pizza, breads, buns, cookies and more,” the company highlights.

North Hall

6550

Heinen

Heinen will showcase its most in-demand machines: the compact, compact duo, ambicol, acticool, proofline, and arctic. “In business since 1982, we’ve built a reputation for durability — our machines have a lifespan of up to 30 years,” Heinen underlines. The company ships 1-2 machines worldwide weekly.

In North America and APAC, there is a strong demand for high-throughput and space-efficient freezing solutions for automated production lines. These markets often prioritize energy efficiency and hygiene design. In Europe, the focus is frequently on customized solutions and integration into existing infrastructure – here, flexibility and long-term serviceability are key, Heinen shares.

West Hall

509

Hobart

At Hobart’s IBIE stand, the recently upgraded Legacy+® HL600 60-quart mixer will he displayed. Hobart added an exclusive NoChipMax™ System to the mixer, which includes a NoChip™ aluminum planetary with a metallic gray hybrid powder finish that is scratch- and corrosion-resistant and prevents paint chipping. Also, as part of the system, Hobart included a NoChip #12 attachment hub with a stainless-steel insert and die cast cover. These features prevent paint chipping when using a VS9 slicer attachment.

Food preparation equipment designed to improve productivity for bakeries of all sizes will also be presented.

West Hall

1311

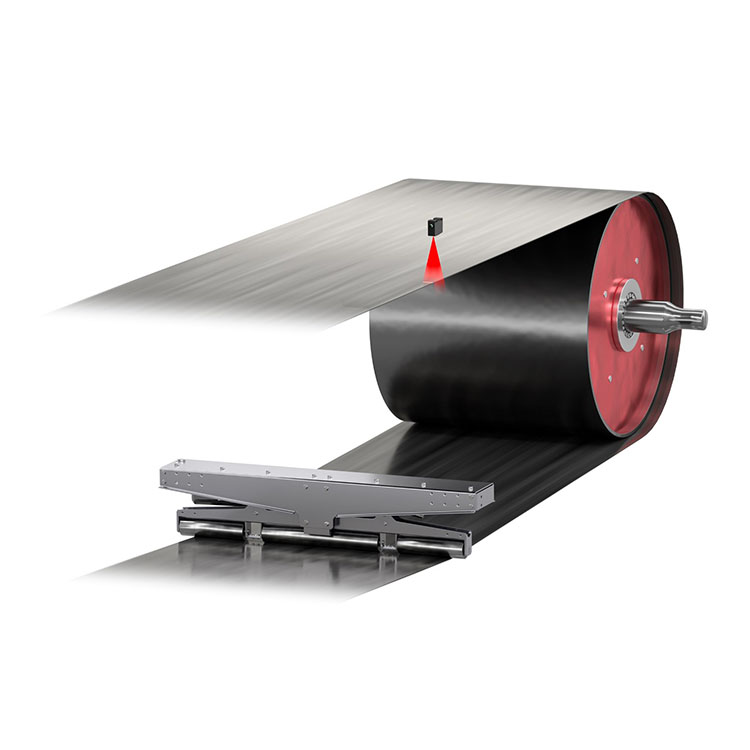

IPCO

IPCO will showcase the recently launched Compact Belt Tracking system, CBT 2G, a major addition to its expanding range of conveyor components. Live demonstrations will be organized. This system uses a contact-free optical sensor to continuously monitor belt position and instantly correct any deviation: “The result: precise, responsive tracking and extended belt life, even in demanding production environments,” IPCO explains.

IPCO will demonstrate how its steel belts, processing systems, and deep industry expertise can help bakery, chocolate, and confectionery producers boost productivity and streamline operations. The company’s conveyor solutions portfolio includes everything from sheaves and shafts to bearings and breakpoints. Alongside equipment, IPCO offers expert troubleshooting, consultancy, and oven upgrade services, including transitions from mesh conveyors to high-performance steel belts.

North Hall

5663

IREKS

IREKS will present new and innovative baking ingredients. The AROMA & TASTE Concept will be highlighted, with premium malts and sourdoughs, bread bases such as a Mediterranean mix, Chia mix and Multiseed mix. “We will showcase and demonstrate their ease of production and safety in creating outstanding and trendy baked goods,” IREKS says. Solutions for gluten-free and vegan products will also be presented at the stand.

IREKS’ daughter company DREIDOPPEL will showcase sweet pastry solutions, including diverse pastes for fine pastry, which contain natural flavor and color and are mainly gluten-free and vegan. “Via our SWEET TABLE Concept, visitors can get a feeling of the various applications they can be used for,” the company anticipates.

West Hall

3865

Koenig

Koenig will showcase the Artisan SFE EC dough sheeting line for the very first time in the US at IBIE. The ‘E’ stands for efficient production through endless dough sheeting with no edge trim, meaning zero dough waste. The ‘EC’ – Easy Clean design saves time and resources for highly efficient cleaning, maintenance and product changes, Koenig highlights. The line has a dough throughput of up to 9,000 pieces/h in a six-row operation. It can produce dough sheets from 10 to 19 mm thick.

The company will also display the Fortuna semi-automatic machine that produces high and round dough pieces consistently, with weights from 32 to 110 g. It has a compact design and can also be used as a reliable dough dividing machine.

Koenig will also showcase the dough dividers and rounders Mini Rex Multi and Rex Futura Multi and the spiral mixer SP 160 at IBIE. Automation and robotic solutions will pe presented, together with its partner Abendschön.

West Hall

535

KPM Analytics

At IBIE, KPM will exhibit its AI-powered vision system capabilities for the first time, and will highlight its food-safety technologies equipped with hyperspectral imaging. “For the baking industry, hyperspectral imaging offers vital quality control applications to inspect products within the non-visible spectrum, extracting the chemical footprint of a product’s surface,” KPM explains.

The company will also highlight its recently launched Mixolab 300 Universal Flour & Dough Analyzer. An upgrade to the Mixolab 2, Mixolab 300 is a new design that also includes a new mixing bowl and analytical protocols for at-line dough testing. “This new design is a major value to bakeries that wish to test doughs directly off the line – including crumbly dough or liquid batters – and quickly assess their properties in as little as two minutes,” the specialist adds.

The entire suite of solutions that help manage product consistency, improve process control, and contribute to making data-driven decisions will also be presented.

West Hall

2117

Kwik Lok

At IBIE, Kwik Lok will demonstrate a full complement of closures, closing machines, printers, and labels. Solutions for bakeries of all sizes will be presented and new developments will be introduced at the stand. “A key feature of our booth will be the new 872 Plus.

The 872 Plus is engineered for maximum performance, minimal maintenance, and the lowest total cost of ownership we’ve ever offered” Kwik Lok details.

Sustainable closure solutions will also be showcased, including a new member of the Enviro-Lok family: the Enviro-Lok PE. “The Enviro-Lok PE is a great way to move toward a circular packaging solution and is designed to run in current Kwik Lok machines. It is also metal free!”, the company explains. Labels welded without glue onto closures, also contribute to more sustainable solutions, for easy recycling. Labels can be used for traceability and added communication with marketing opportunities.

West Hall

3625

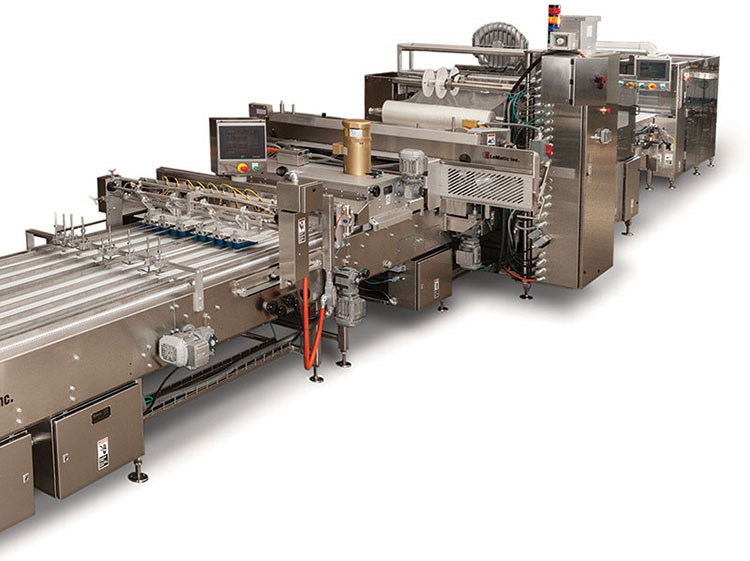

LeMatic

At IBIE, LeMatic highlights its updated LS133 Bulk Packer, including new technologies in cross-sealing and band-sealing, motorized film spindles, and a servo-driven motorized re-grouper. The company will present its entry-level equipment for bakeries upgrading from manual to semi-automatic or automatic operations, including its LX3 Variety Bagger, which can be used for a large variety of products for bakeries doing short runs with multiple changeovers; and the SLS Single Lane Slicer, for slicing single or dual lanes of product.

The P7 Pattern Former & Loader will also be on display, which allows operators to create and manage product patterns directly through the HIM interface.

West Hall

2333

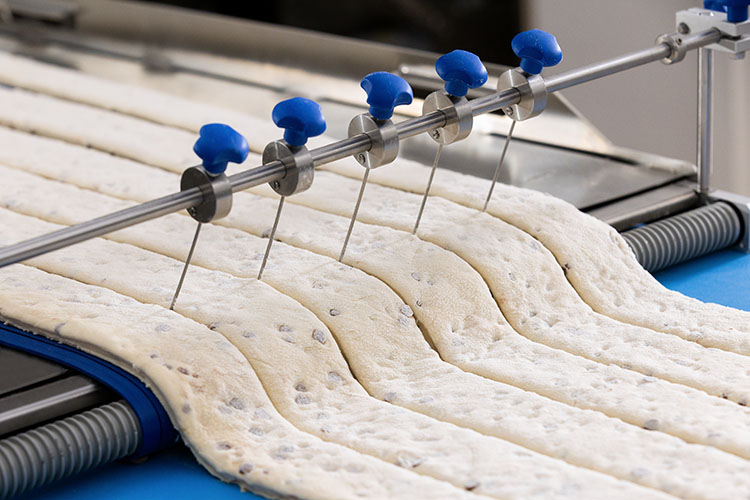

MECATHERM/ABI

MyMecatherm, a customizable digital platform, will be highlighted at IBIE – a solution that facilitates real-time equipment monitoring and enables predictive maintenance. Make-up lines will be displayed, including the M-NS II divider and the M-RT moulder for working with hydrated and rested doughs. The new flexible M-VT vertical oven will also be highlighted.

MECATHERM will exhibit alongside its sister company ABI, which will also unveil its new KATANA II Robotic Scoring Solution for the first time at IBIE 2025. Visitors can discover the new equipment and attend live demonstrations. It offers high flexibility and optimal scoring precision and adapts to a wide variety of doughs and products.

Finally, industrial bakers will discover solutions to make energy savings and eliminate product waste from their production lines by utilizing Hygro Control System, Energy Recovery System, and ABI’s AI-powered EYE-Q quality control solution.

West Hall

1025

Middleby Bakery Group

Middleby will highlight oven technology, with a dedicated ‘Oven Alley’ at the show. The latest advances in baking will be showcased here, from consistency to efficiency and sustainability concepts. Conveyor-driven ovens from Stewart Systems will be among the technology solutions displayed, with optimized heat distribution, flexible grid design and floating magnets – designed for breads and buns in industrial operations. Sveba Dahlen’s S-series ovens will also be displayed, as well as GBT’s Mistral Tunnel Oven, with energy-saving, eco-efficient technology. Auto-Bake Serpentine completes the oven portfolio on display, featuring hybrid gas/electric industrial ovens.

With its extensive portfolio of brands, Middleby will offer full automation concepts, with processing lines and system integrations.

West Hall

1631

Peerless, a brand of Coperion

Peerless will present solutions specializing in mixing, dough handling, and sandwiching operations. All Peerless mixers are custom-built with an extensive range of options in bowl capacities, tilt configurations and refrigeration packages. “Our Peerless Peters Sandwiching equipment is designed to reduce sanitation downtime and provide consistent product quality and high production rates,” the company highlights.

Integrated within end-to-end systems, Coperion brings together a family of renowned brands – that alongside Peerless also includes Baker Perkins, Bakon, DIOSNA, Kemutec, Shaffer, Shick Esteve, Unifiller, and VMI.

West Hall

3445

Rademaker

Rademaker will unveil its latest advancements at IBIE 2025, including solutions for croissants, bread, Danish and puff pastry, pies and quiches, pizza, donuts, pita, and other flatbreads. Its latest Pizza Topping Line will be showcased, designed for fully automated pizza production, including the new Pizza Sauce Depositor, which makes its debut in the North American market. The line also includes the Pizza Strewing System, which can optimize working with all types of topping materials, such as cheese, vegetables, IQFs, and meats, thanks to smart data gathering.

The new Radini Semi-industrial Bread Line will also debut in the North American market, with a capacity of up to 1,200 kg of bread dough per hour, supporting a wide variety of doughs.

An enhanced laminating system, three years into development, and a new bread line pre-sheeter will also be on display, along with the Charlie folding unit from the newly acquired company Form & Frys.

West Hall

3811/3801

Reading Bakery Systems

Reading Bakery Systems will showcase its full portfolio of snack production solutions, headlined by the new Emithermic XE Oven, a more sustainable, balanced baking platform that replaces traditional DGF ovens. Also featured will be the company’s latest sheeting line for biscuits, crackers, and crisps, and the flexible Low Pressure Extrusion System for a variety of baked snack and pretzel products.

Visitors can also explore Exact Mixing continuous mixing systems, Reading Thermal oven profiling technologies, and RBSConnect, a smart monitoring and optimization platform supporting Industry 4.0 innovation. Together, these innovative snack solutions help bakeries improve efficiency, product quality, and energy savings.

West Hall

2845

RONDO

RONDO’s newest make-up line, Starline 5, will be introduced at IBIE 2025. It was developed over the past five years to meet all challenges in everyday production, with several new key developments, including a redesigned conveyor table, which optimizes hygiene. It is flexible in production for a wide variety of pastries and bread rolls, coming with a comprehensive variety of accessories

The RONDO CS Line (part of the ASTec Croissant Line – for curling and turning dough triangles) will also be presented. In addition, the company’s collaboration with the Swiss bakery school Richemont will be highlighted.

West Hall

201

Schubert

The Flowpacker system is the heart of this year’s Schubert North America exhibit. The company’s advanced horizontal flow-wrapping solution is designed to integrate seamlessly into modular packaging systems and features a fully automated pick-and-place system that gently handles delicate baked goods such as croissants, pastries, and cookies, ensuring high-speed performance with minimal waste.

“Our goal at IBIE is to show how the Flowpacker provides the perfect combination of efficiency, flexibility, and product protection—especially for bakeries needing a future-proof solution,” says Hartmut Siegel, CEO of Schubert North America. “Visitors will see how it adapts easily to changing formats, materials, and production volumes.”

West Hall

1637

Shaffer, a brand of Coperion

Shaffer will be among the brands showcased by Coperion, with its mixing technology. Shaffer’s custom industrial dough mixers are engineered to be sanitary, durable and innovative and are used to mix bread, bun, cookie, biscuit, cracker doughs, and more, the company highlights. In addition, Shaffer technologies at the stand will include dough chunkers and conveyors that feed chunks of dough from the mixer area to downstream dividers or forming equipment.

West Hall

1829

Shick Esteve, a brand of Coperion

Shick Esteve will showcase a minor ingredient platform with hand dump, including the IQC filtration on display, as well as the Laramore conveyor vacuum and roll line at IBIE. These are alongside the bulk liquid storage tote and liquid fermentation system. All these solutions are integrated into an overall dough display system, in which Shick Esteve represents the ‘Systems and Ingredient Automation’ technology for Coperion.

West Hall

1025

Sveba Dahlen

At IBIE, Sveba Dahlen will showcase its ovens and the Glimek bread systems this year. A flexible bread system with a capacity of 1,800 dough pieces per hour will be on display, suitable for a wide range of different bread products. “There will also be a tunnel oven mockup showing both the principles of electrical heated oven as well as the gas heated oven,” Sveba Dahlen anticipates. Sveba recently partnered with Exodraft for heat recovery, to offer concrete energy consumption assessments. Together with its partner Gemini Bakery Solutions, the company will also show the entire range of Sveba Dahlen rack ovens at their own stand (West Hall, 2544).

West Hall

2245

Tonelli

This year, Tonelli will exhibit the 600 l (1,000 lb batch) Vertical Planetary Mixer and Product Transfer Pump. This system will automate mixing and pumping 4,000 lbs per hour of all kinds of cake batters, cake donuts, icings, and more. The Italian specialist also highlights new innovative solutions for thermal mixing automation, continuous systems, and turnkey industrial cake lines.

Patrick Wilkinson, North American Sales Manager, comments: “This year, we will demonstrate the benefits and return on investment of automating the front end of your lines at the Tonelli booth. From ingredient dosing to product transfer, to automatic washing, Tonelli planetary mixing systems have a solution to scale and automate almost any application in the bakery.”

West Hall

1625

Unifiller, a brand of Coperion

Coperion will highlight its Unifiller brand technologies from its extensive line of specialized and automated portioning solutions. “Our compact or fully automated systems include single-piston and multi-piston depositors, food pumps, filling machines, cake and cupcake decorating equipment, pastry machines and more,” the specialist details. Unifiller equipment focuses on integrating automation to reduce product waste through accurate portioning and dosing, while streamlining operations to reduce downtime and drive manufacturing.

West Hall

2070

Verhoeven Bakery Equipment Family

Verhoeven will showcase its turnkey solutions, vacuum cooling and baking solutions, as well as its latest bread recycling solutions, which put sustainability into practice by reducing waste. Vacuum cooling and baking will be demonstrated live at the stand.

“We are proud to introduce an innovative concept: Repeatloaf – The Final Concept,” Verhoeven anticipates, a new machine concept that fully automates return bread processing. Within 24 hours, leftover bread is converted into a dry, stockable powder. The end product has many applications, from a flour alternative, as decoration, or to enrich dough.

West Hall

1837

VMI, a brand of Coperion

VMI mixers and kneaders that are specially designed for artisan bakers, catering professionals and large-scale bakery production will be presented at Coperion’s IBIE stand. They cover all mixing technologies, including pre-mixing, batch mixing, continuous mixing, planetary mixing, fermentation, automated systems, and more. Equipment on display in Las Vegas will include VMI’s Continuous Mixer, Batch Mixer and Planetary Mixer. VMI Automatic Guided Vehicles (AGV) will also be featured alongside Coperion’s brand DIOSNA.

Follow www.bakingbiscuit.com and the BakeryMirror newsletter for more information from the exhibitors, including their insights on the European and the North American markets!