DEBAG’s blast freezer for cooling and freezing. It is suitable for products hot from the oven as well as unripe and fully proofed dough pieces

DEBAG’s blast freezer works according to the suction principle. The air flows over each individual tray, thus ensuring that the products are cooled in a uniform way. The blast freezer works in a temperature range from – 30 to + 5 °C and is suitable for cooling and freezing of products hot from the oven as well as unripe and fully proofed dough pieces.

The easy-to-use control unit is located on the front of the cell as standard. In combination systems, however, it can also be placed in a control cockpit above the cell door. The temperature control can be based on either the room or the core temperature. The high-performance evaporator is suspended, which ensures that the base of the unit can be cleaned easily.

In addition to the continuous operating mode (manual), it is also possible to control the cooling process automatically over a specified time or a defined final temperature (automatic). To prevent heavy icing on the evaporator, a defrosting process can be started manually with the door open.

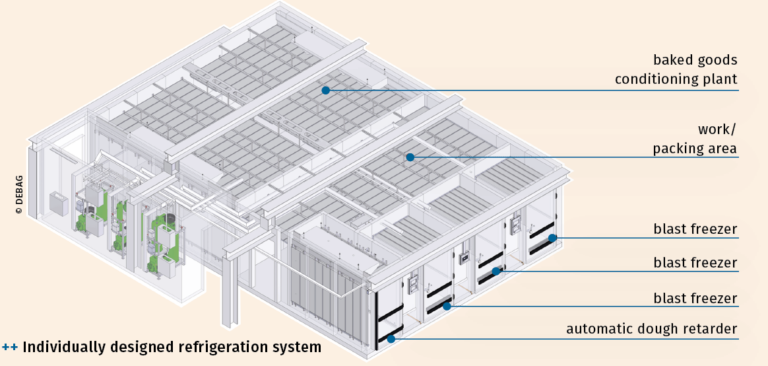

Individually designed refrigeration system