Bühler launched the CompactMix, a new solution that combines mixing and grinding technologies for the production of confectionery masses for spreads, fillings and other applications. It was designed to meet shifting demands in chocolate and confectionery production, the Swiss technology company underlines: “With ongoing price volatility in cocoa markets, manufacturers are increasingly turning to chocolate alternatives that allow for a greater variety of formulations without compromising taste and quality. The global increase in demand for on-the-go products, such as filled biscuits, wafers, and snack bars, also requires production systems that offer the flexibility to handle a wide variety of recipes.”

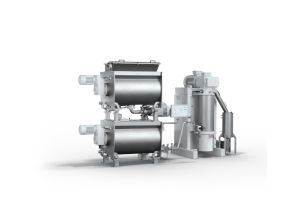

CompactMix brings together the ShearMix mixing system with a spiral agitator for fast, uniform mixing and the Aurora ball mill to reduce particle size. This combination ensures optimal mixing and refining performance, Bühler explains. The system delivers uniform textures with particle sizes below 20 microns, resulting in a smooth mouthfeel. It can handle everything from low-fat to high-fat recipes.

The CompactMix uses up to 30% less energy than conventional models, the company estimates. It can be scaled from 400 kg/h to 3,000 kg/h, making it suitable for both small-scale and industrial production.

“CompactMix gives manufacturers the freedom to craft premium chocolate spreads, fillings, and coatings with exceptional quality and consistency. Its flexible design supports a wide range of ingredients, encouraging creativity and innovation in developing modern confectionery masses,” says Skeljzen Nesimi, Head of Product Management Chocolate & Coffee at Bühler.

The CompactMix is equipped with digital features to allow full control over production. Real-time monitoring, recipe management, and smart control features optimize consistency, reduce waste, and ensure every batch meets the desired fineness and taste profile. These digital tools also allow customers to adapt recipes to different consumer preferences, track performance, and maintain products at high quality.

CompactMix can be integrated into Bühler’s complete chocolate processing line..

“With CompactMix, we are not just launching a new solution – we are enabling our customers to rethink chocolate production. From raw ingredients to finished products, Bühler provides the technology and expertise to support every step of the process, helping customers craft the chocolate of the future, delicious and affordable,” says Skeljzen Nesimi.

Photos: Bühler