Weber Bakery

Davos is located at an altitude of 1,560 meters in the Swiss Alps. The city is not only the highest in Europe and a world-renowned health resort; above all, it is chic, sophisticated, and expensive. Anyone who wants to survive here has to be able to deliver top performance. This also applies to Weber Bakery, which supplies almost all 4- to 5-star hotels and other discerning customers in the town.

With a passion for his craft, Rolf Weber, Weber Bakery’s Managing Director, is a fourth-generation baker. He demands nothing less than excellence from himself, his employees and his suppliers. The Weber bakery has won numerous awards and was honored with the Bäckerkrone (Baker‘s Crown) in 2019. Rolf Weber also excels in the supreme discipline of the baking trade, baking with natural sourdough, at the highest level: his panettone is considered the best north of Italy. When someone like him writes a thank you letter to Dinkelsbühl about a bread roll production line, that’s reason enough to follow up on it.

Working two shifts during peak season

Anyone who wants to reach the 37-year-old master baker and trained chef in March will need patience. From the beginning of December to the end of March is peak season in Davos, when the 550-square-meter bakery at Promenade 148 in Davos Dorf operates in two shifts. It’s a good thing that the WP MINIROLL roll baking system was available for delivery, installation, and commissioning in a short time in the fall and was adapted to his requirements for particularly soft dough. Fortunately, he is happy to talk about his ideas of quality and perfection.

The Weber family has been baking in Davos Dorf since 1903. The fourth generation owners, brothers Rolf and Adrian, now run the business. Rolf is responsible for production, purchasing, hygiene, and sales to major customers, while Adrian takes care of administration and the restaurant. The seasonal business, which is also located in a place that inspired Thomas Mann‘s novel ‘The Magic Mountain’, is tough and demands everything from employees, managers, and the family. The shop is open continuously from 6 a.m. to 8 p.m., and the restaurant serves hot delicacies from 11:30 a.m. to 7:30 p.m.

”The system makes work easier for our employees, and we are also finished with roll production one to two hours earlier.”

Rolf Weber, Managing Director, Weber Bakery

WP MINIROLL: The new small roll line for the Weber bakery

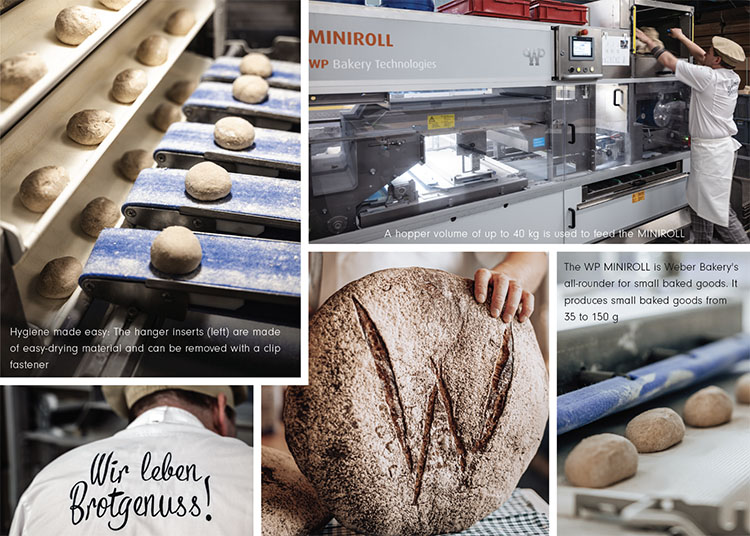

The MINIROLL is a compact roll line with a small footprint, a relatively large variety of products and a high hourly output of up to 4,000 pieces in green mode. The system is ideal for artisan bakeries for the automated production of small baked goods with artisan quality and appearance.

The small bakery line is the all-rounder in the bakery. Long rolled rolls, smooth round rolls, also in cylindrical form, small baguettes, but also buns for hamburgers or hotdogs with a dough weight of 35 to 150 g are produced with high weight accuracy using the compact system.

The interchangeable pressure boards and the driven upper belt make this variety possible. Simple cleaning and automatic weight adjustment make product changeovers easier.

The MINIROLL is equipped with a dough-protecting drum molding system, an adjustable molding belt and variable pressing pressure. The bypass belt enables direct processing in eco mode, without a proofer. The program-controlled depositing device means that commercially available fermentation product carriers can be used. The intensive sterilization station, the stainless steel design and the simple removal for cleaning all dough-carrying parts ensure a high standard of hygiene.

The dough pieces can be processed directly via the side discharge

Delivery makes up for more than 50% of the business

The upward trend has been particularly steep over the past eight years. In 2016, production was expanded from 150 to 550 square meters. In 2019, the business was awarded the Baker’s Crown by the Swiss Bakers and Confectioners Association (SBC). And, in 2021, the range of natural sourdough breads and baked goods was introduced, as well as the ready-to-eat range of pre-baked, frozen breads and baked goods for local and regional top restaurants and hotels. Since 2022, the Weber

bakery has also been supplying the Aurora bakery and pastry shop in Lenzerheide, about a 50-minute drive away. It supplies 35 hotels there. The delivery business now accounts for over 50% of the bakery’s turnover. The other half is generated in the restaurant and in its own shop.

“Production is optimized in terms of business management and organization,” says Rolf Weber – after the WP MINIROLL roll production line was installed in November 2024. The entire range of rolls, small baked goods, and brioche buns is now produced with it – up to 14,000 pieces per day in peak season. The simple adjustment options and automatic weight adjustment make it easy to change products. “The system makes work easier for our employees, and we are also finished with roll production one to two hours earlier,” says Rolf Weber, who is convinced of the investment.

The small baked goods are removed directly onto trays and pushed into the rack trolley

Bakery-Confectionery-Café Weber AG at a glance

Managing directors: Rolf and Adrian Weber

Employees: up to 45, including 19 in the bakery

Products: over 200, including diverse artisan breads, small baked goods such as rolls and buns, its trademark pear bread and fruit-and-nut loaf, as well as a variety of pastries, cakes and snacks

Website: www.weber-davos.ch

“The result is always what counts”

Previously, Rolf Weber‘s team had been struggling with the existing machine, which required extensive manual work to handle the bakery’s wide product range and short-term orders. The range includes small baked goods weighing between 34 and 130 g, in round and oblong shapes. Some products could not be produced on other machines due to their low weight.

With the MINIROLL, however, this is possible, as the double-piston system of the MULTIMATIC molding machine allows for weights ranging from 35 to 150 g. This was not the only factor that convinced Rolf Weber during a test of the machine with his own doughs at the WP Baking Center in Dinkelsbühl.

He acknowledges the importance of the gentlest possible dough dividing and molding process for the quality of the baked goods. The MINIROLL is equipped with a drum molder system that is gentle on the dough, an adjustable molding belt and enables variable molding pressure. “The result is always the decisive factor,” says Rolf Weber. The result of his best-selling signature product for the

catering and hotel industry convinced him – a round, 48-gram ‘balloon bun’. It’s a golden yellow, almost round cookie made from wheat flour.

And there was something else that impressed the perfectionist: the weight accuracy it could achieve. Each piece of dough is the same size and weight.

The MINIROLL is also equipped with a side discharge. Dough pieces are discharged after intermediate proofing for further processing into pretzels, Danish pastries, or other baked goods. The Weber bakery processes very soft doughs (TA 175), which also have a strong tendency to stick due to the long dough resting time, of up to 48 hours. To avoid dough residues on the discharge conveyor belt, this was modified to meet Rolf Weber’s requirements. “It was great that a solution was found so quickly so that the system was perfect for us,” he says, impressed by this passion for perfection.