Catalina Mihu reporting The 38th AIBI Congress brought the baking industry together this year for the moment’s most important topics,…

By Catalina Mihu True to its motto, ‘Standing still is a step backward’, Kempf successfully completed its ambitious relocation project…

Dough folding, dough rolling and, most importantly, dough separating: the quality of several product ranges relies on perfect, consistent laminating…

Better-for-you preferences also apply to bread. Several mixing options help increase production volumes while providing goods that still feel and taste artisan-made.

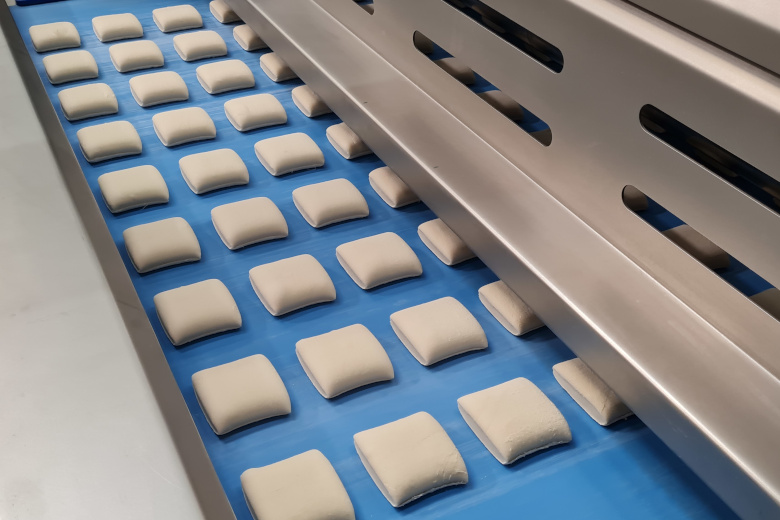

The stress-free sheeting technology developed by AMF Tromp is at the heart of the processing line for any artisan bread product. The technology was developed around maintaining the quality and integrity of the traditional craft.

An enticing range of breads is carefully crafted to answer the consumer’s unwavering love for a slice of wholesomeness, whether…

A study by Food2Multimedia Pandemic, war, inflation, skilled worker shortage – how are such crises affecting the investment behavior of…

Technology is optimized to meet the clear trend for flexible equipment that can support changes in production and a diverse…

iba 2023 After the pandemic and while navigating war disruptions and ensuing instability, the baking industry warmly celebrated the time…

This year, RONDO returns to iba with a focus on solutions for breads and croissants, complete with live demonstrations of its latest solutions and features. Ahead of the fair, Fabian Bossard, head of the Marketing & Communications Department, shared details about the show preparations and the company’s current focus.