Designing the turnkey line that fits best with a given environment throughout each process step also starts with people: the design team tasked with bringing together only the perfect pieces of the puzzle that will become a new line.

Grupo Bimbo launched its 2023 annual report, titled ‘Behind our Actions’, with progress on its commitments for 2030 and 2050. Almost all (93%) of its packaging is made of recyclable materials, the document shows, highlighting the company’s sustainability advances.

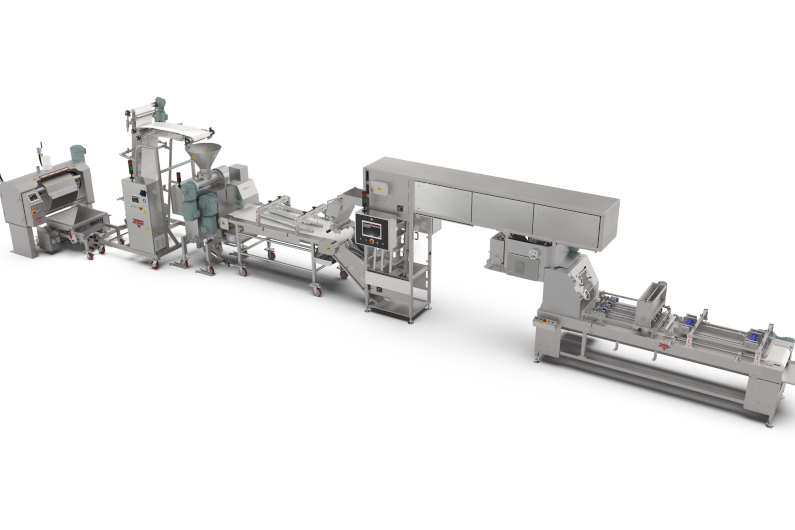

The APEX Mini Combo BDR Bread and Bun System by AMF Flex won this year’s ‘Innovation for Growth’ award at Bakery China. AMF Bakery Systems (AMF) developed this system focusing on automating processes and improving efficiency as well as efficiency in the production facility.

By Catalina Mihu True to its motto, ‘Standing still is a step backward’, Kempf successfully completed its ambitious relocation project…

Dough folding, dough rolling and, most importantly, dough separating: the quality of several product ranges relies on perfect, consistent laminating…

Correct and consistent dough dividing will amount to valuable material savings over time. At this stage, less (extra dough unnecessarily…

An entire fleet of iconic crackers built its consumer base on their open, flaky texture, which is produced by layering…

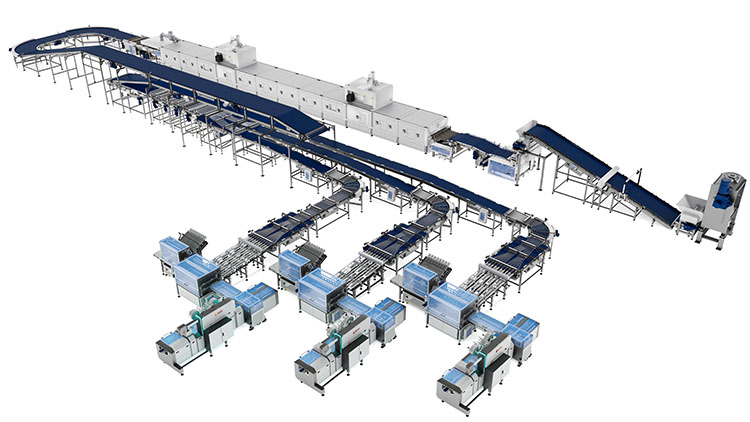

PART I Automated production lines are the solution to optimizing production and optimally allocating resources, including a critical one: the…

PART I Soft dough biscuits are among the popular snacking choices worldwide. Their success comes, in no small part, from…

From the beloved classics to the unexpected modern creations, the finest viennoiserie and puff pastries enjoy unwavering commitment from consumers….