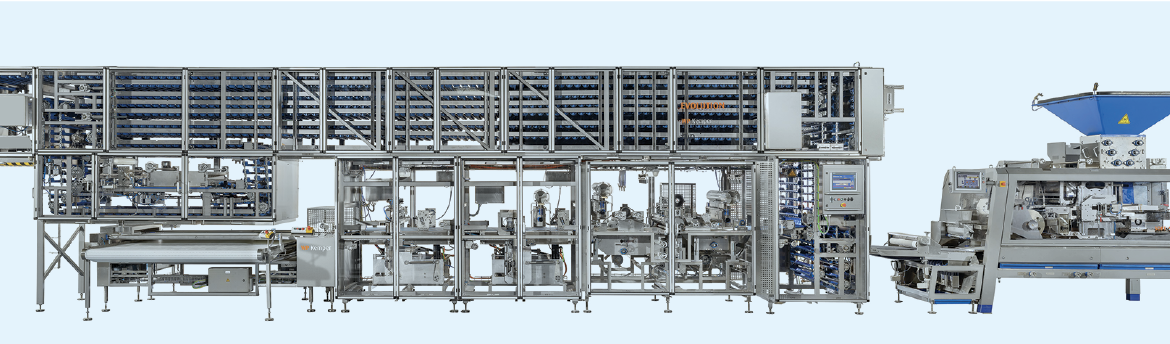

WP ROLL is the name of the system consisting of the EVOLUTION bread roll machine and the SOFT STAR CT high-performance dough divider from WP. Production is gentle on the dough, precise and hygienic.

WP BAKERYGROUP develops and installs production systems in the field of industrial bread roll production as turnkey solutions from the dough production to the finished product. This includes delivery, installation and commissioning as well as the necessary service. The heart of the industrial bread roll production is the EVOLUTION bread roll plant with the high-performance dough divider SOFT STAR CT. The high-performance dough dividing & rounding machine and the further developed EVOLUTION have been designed for multi-shift operation. The system is also suitable for the automatic processing of all commercially available bread roll and boiling doughs.

The maximum hourly output of the EVOLUTION industrial bread roll machine is 36,000 pieces. The total output has increased by 20 % compared to the previous model due to moving modules and new high-performance drives. The advantage: higher productivity, faster return on investment and less personnel and space requirements in relation to the hourly output. Due to the modular design, different products can be produced on just one system, allowing the company to respond to seasonal differences in the product range. The subsequent expandability leads to long-term variability in the product range.

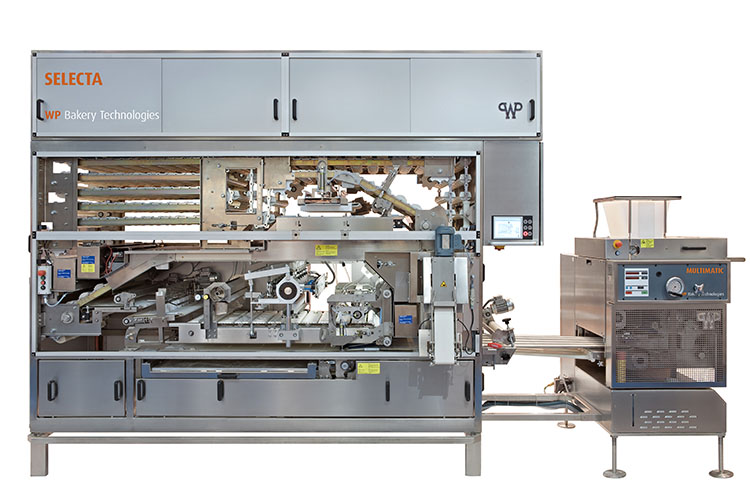

The bread roll machine Selecta Modular stands for a flexible and modular machine concept

Easy to operate

The designers attached particular importance to the ergonomic design for easy cleaning of the plant. The EVOLUTION has hinged doors and the SOFT STAR CT has a large access flap, which facilitates access for cleaning. In addition, all parts in contact with the dough can be swivelled or removed inside the machine and the dough processing is separated from the drive area. The drive and dough processing areas are completely separated from each other. Due to the balcony construction, all functional components are freely accessible.

The system is easy to operate via the INUS user interface, which is used throughout all WP Kemper systems.

Similar to all dough dividing and rounding machines of the SOFT STAR series, the SOFT STAR CT also produces the dough pieces particularly gently and with 99% weight accuracy, the company announced and added that the EVOLUTION processes soft and demanding doughs very precisely. Due to upstream alignment stations, the transfers are very precise and ensure exact placement on, sheets and peel boards, thus ensuring high product quality in industrial bread roll production.