Mecatherm, French manufacturer of industrial ovens and production lines, has signed a partnership with American ABI Ltd, a specialist in bagel makeup equipment. Together they are planning to market an industrial bagel line. baking+biscuit international investigates further.

Worldwide, there is a growing market for bagels as a sandwich variant in the fast food industry and this forms the background to the collaboration, which was initially limited to the offer of industrial bagel lines. The dough for the ring-shaped yeast bread roll can be varied with any sweet or savory ingredients and due to the compact structure of the dough, it retains stability until the very last bite.

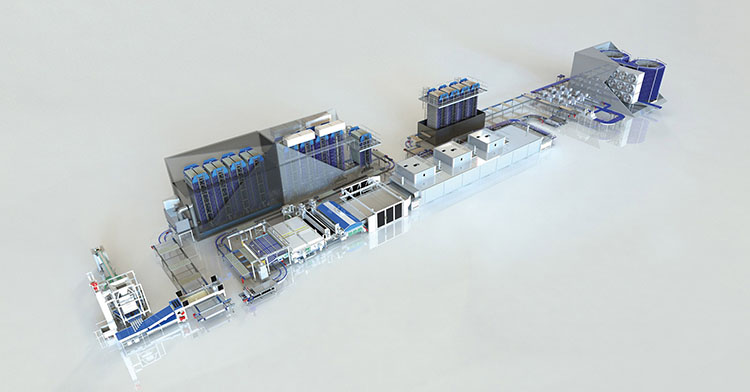

The joint offer from Mecatherm and ABI bears the symbolic name MECABAGEL, with the stations forming, cooking, seeding and drying from ABI, and fermentation, baking, cooling and freezing from Mecatherm.

The bagel in its original form comes from the Jewish communities in Eastern Europe. Emigrants brought it with them to the USA, where it developed from coast to coast into a standard bread roll that needs to be present on every supermarket shelf. Special feature: a real bagel is passed through boiling water before baking, so that the surface closes up and the finished bagel has a dense dough structure.

ABI has developed a very special solution for the cooking process. The technology used to cook bagels is what is referred to as “waterfall” style boiling. This method incorporates a boiling-hot waterbed, which generates an abundance of steam in the boiling chamber as well as when in contact with the bottoms of the bagels. In addition, the bagels travel through a series of hot water “curtains”, which coats the upper three quarters of the bagels as they pass through the curtains. This combination ensures an even, constant exposure to the boiling water and steam. Belt speed adjustments are used to achieve the desired cooking time. Waterfall technology consumes less water, as the heated water of the bed is pulled through a filter and drawn up to the waterfalls.

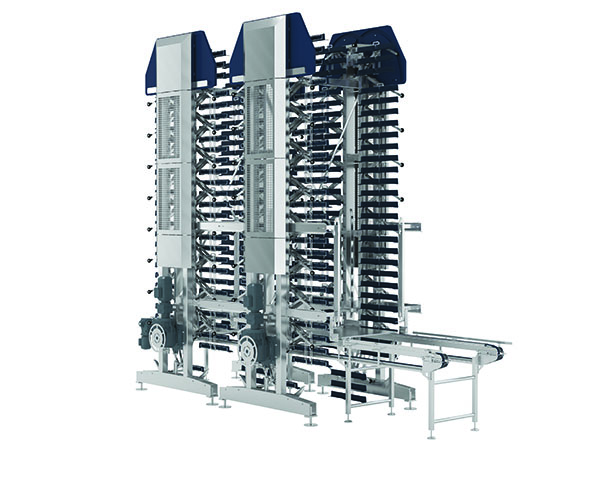

Mecatherm does not use the traditional spiral solution for cooling, but the modular M-UB solution that improves hygiene and changeover management, as well as packaging stops. The new solution involves an independent cooling circuit, using cooling trays on a dedicated conveying loop and a modular M-UB cooler. François Retailleau, Production lines manager at Mecatherm, explains why.

“The Mecabagel cooling circuit provides the producers with tools to improve their hygiene control:

+ An independent cooling circuit limits contamination risks, which are further controlled when enclosed into a “clean room” area.

+ Dedicated cooling trays are easy to wash down. This is usually a tricky operation because every connection between links is a potential retention area where bacteria can grow.

+ Moreover M-UB technology has no top pusher, this makes for a smooth friction-free avoiding all kind of pollution risk.

As this solution uses pans, it is also possible to add a buffer in the cooler, thus allowing packaging stops to be managed (e.g. due to changeovers) without stopping the rest of the line upstream. This functionality – which is not available with continuous systems such as spirals – plays a key role in improving the overall line performance.”

Key stages on the MECABAGEL production line

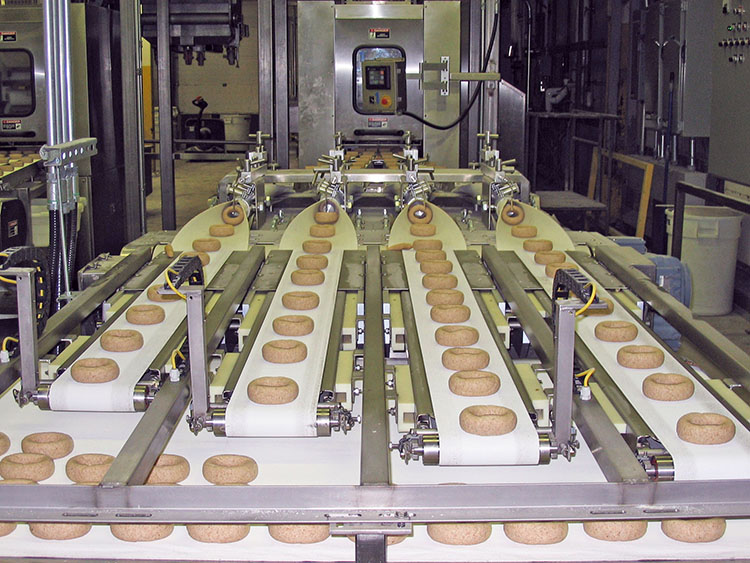

1. Dough cutting and shaping (by ABI)

After leaving the kneader, the dough passes through the divider to obtain dough pieces, which are then shaped and rolled around a shaft to give the bagels their characteristic ring shape

Bagel makeup line

2. Fermentation: Proofing and retarding (by MECATHERM)

Placed on fermentation trays called peel boards the dough pieces enter the fermentation stage. Bagels generally require two-phase fermentation: parboiling at very high temperatures, followed by “retarding” in a cold atmosphere, to stop fermentation and to firm up the product by creating a thin superficial skin

3. Boiling, seeding, drying (by ABI)

The bagels are now taken from the trays in the direction of the boiler. For this stage, a very original spray treatment has been developed by ABI that replaces standard immersion. The boiling stage is completed by seeding to decorate and personalize the product.

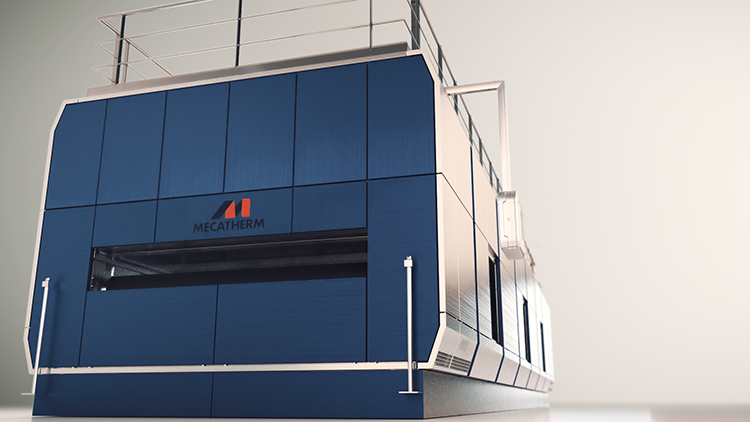

4. Baking (by Mecatherm)

M-TA oven

The bagels move on to the oven where they will be traditionally baked on the floor or hearth of the oven. Depending on market expectations, the hearth of the oven is available with or without marks. For a bagel with a smooth underside, FTP technology with metal bands is recommended; and for hearth marking, the M-TA oven technology is used.

5. Cooling and freezing (optional) (by MECATHERM)

6. Production line mechanization (by MECATHERM)

For proofing, retarding or cooling, the assembly line is equipped with M-UB universal handling systems, which combine aspects of “paternoster” and “swing” type mechanizations

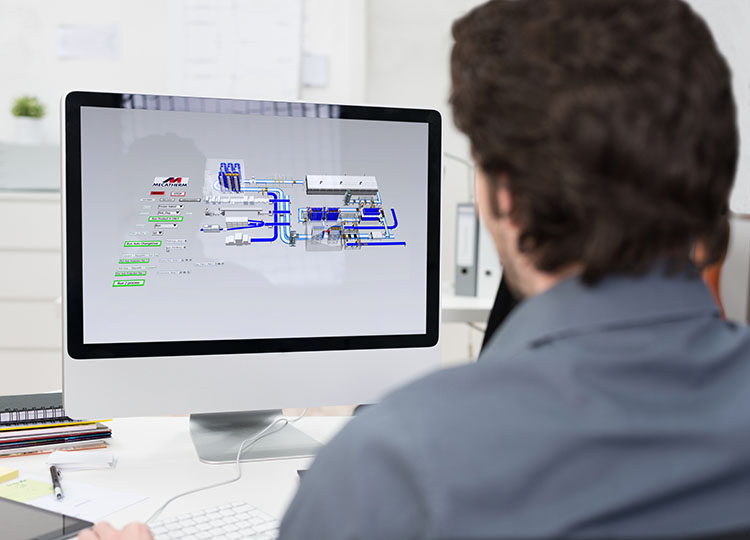

7. Smart-management tools (by MECATHERM)

The MECABAGEL line is equipped with digital user support solutions

+ An instinctive and user-friendly interface that facilitates operation, production monitoring and traceability on the line.

+ A preventive maintenance module that alerts the operator if inspection or maintenance of equipment is required, and provides maintenance recommendations.

Technical characteristics of the MECABAGEL line

+ Floor area: 1,800m² (excluding packaging) – 90 m x 20 m

+ Reference production capacity: 28,000 bagels per hour

+ Reference rate of production: 320 peelboards per hour

+ Dimensions of fermentation and cooling trays: 2,000mm x 800 mm

Mecatherm and ABI report that customers in the respective markets will be referred to qualified providers for dough production if required. “The main challenge to mix bagel dough – characterized generally as being very stiff – is for the mixer to deliver a high level of power; therefore, horizontal mixers or spiral mixers (single or double) are the technologies that are generally used.”

Baking the bagel requires a lot of energy from the start of cooking, to ensure its development and prevent sticking. The dough has been made very sticky in the boiling process. It also requires mastery of baking parameters and especially control of the humidity of the oven. Depending on market expectations, the hearth of the oven is available with or without marks. For a bagel with a smooth underside, FTP technology with metal bands is recommended; and if a hearth marking is acceptable, M-TA oven technology can be used.

Maintenance and repair are according to the recommendations of each manufacturer. It is essential that the customer has a smooth transition period, and so once the contract has been signed, a single contact point will be defined for project management, as well as for servicing and maintenance once the line has been installed.

About ABI LTD

ABI is based in Toronto, Canada, and is one of the leading designers and manufacturers of bagel makeup equipment. The company, headed by founder and CEO Alex Kuperman, employs over 75 people across its engineering, production, service, sales, and admin functions.

Each manufacturer has their own dedicated control system to maintain control of their own pieces of equipment. Integration is carried out by establishing communications between the systems, which allows each system to provide the relevant information to the next one. The French mechanical engineering company offers smart management tools as an instinctive and user-friendly interface that facilitates operation, production monitoring and traceability on the line. A preventive maintenance module is also supplied that alerts the operator if the equipment needs to be inspected or maintenance is required; maintenance recommendations are also provided. At present, this transatlantic cooperation includes bagel lines for Europe, Asia, Australia, Mexico, South America, the Middle East and Africa.

About MECATHERM

Founded in 1964, MECATHERM is a French manufacturer of industrial ovens and production lines. The company has two production sites in France and worldwide three sales offices in France, Mexico and Malaysia as well as a subsidiary in Atlanta, Georgia (USA). The company, headed by its President Olivier Sergent, employs more than 400 staff.

The 2 partners add: “We want to first of all develop it in the countries where we can find new opportunities and where ABI Ltd does not have a market. Our future collaboration could be extended to other projects.”