A pain au chocolat at breakfast, a Danish pastry with coffee, a pasty for lunch – indulgent moments that everyone loves. For over twenty years, Rademaker’s Universal Make up line ranging from a laminator or bread line has made the production of a wide range of dough products possible to tickle the taste buds.

A comprehensive update of the line is aimed at making production even more efficient and the name is changing as well to Universal Pastry Line. Rademaker reports that operation is easier and more intuitive, fewer ingredients are wasted, the machine line requires less maintenance and meets the highest hygiene and safety standards. Rademaker’s System Architect, Jan de Kroon, and Senior Bakery Technologist, Richard van Dooren, were intensively involved in developing the new generation of the Universal Pastry Line. Here’s what they had to say about it.

Rademaker has been making pastry production lines for over forty years. Over the past twenty years, the Universal Make-up line has been at the forefront of production. This line has now been developed and updated using information from the market.

‘Before we embarked on the development process, we asked our worldwide sales team to analyze the needs and wishes of their customers in relation to the development of the Universal Make-up line. Lots of information was gathered, which eventually led to a project assignment,’ says De Kroon. After an initial prototype and the beta version, it is now time to launch the Universal Pastry Line: The Next Generation.

Design philosophy

The key principal to this project was ‘boosting the efficiency of the Universal Pastry Line’. In order to approach the project in a targeted way, a design philosophy (see box) was developed. ‘This was based on five main requirements from the market with additional emphasis on the issues of safety and hygiene. Everything we did with respect to the redesign needed to make the operation simpler and enable multiple deployability and simple tool changes, otherwise you could say, we were just tweaking things,’ De Kroon explains.

The Rademaker Technology Centre (RTC) has acquired a great deal of knowledge of dough processing and other processes over the years. The RTC therefore played an important role in developing the Universal Pastry Line. ‘What was once carried out by the baker is now done on a conveyor belt. In the first instance, the new line needed to operate well from a technical perspective, and that was down to the engineers at Rademaker. It was then important that the line worked as efficiently as possible and yet still achieved high product quality. It cannot be forgotten that dough is a living material and therefore the various processes can easily damage the structure. Rademaker over the years has developed dough processing technology that handles the delicate dough very carefully, from the start of the production process to the final product,’ says Van Dooren. All the modifications were therefore extensively tested in the Rademaker Research and Development Centre and the RTC.

The design philosophy

Requirements from the market:

+ Fast and error-free adjustment of the machine to make different products

+ Reduction of spillages and wasted ingredients

+ Improved cleanability

+ Simplified operation and better ergonomics

+ Reduced maintenance

Comply with regulations in the fields of:

+ Safety

+ Hygiene

Not big or complicated, but useful

The basis of the existing production line fulfilled the needs, so no fundamentally new choices were required. De Kroon: ‘With efficiency improvement being our starting point, we looked at all the eighty units that can make up the line and made improvements. These were not necessarily big or complicated changes but always useful. These varied from small modifications such as indicating the direction of the dough so that the unit is always placed correctly, an innovative lift system for the conveyor belt so that it dries faster after wet cleaning and the introduction of the Tool Assistant, which makes a big contribution to the fast and error-free changing of the line. The result is a machine that every user can operate, even someone without a bakery background.’ Van Dooren adds: ‘The set of Allen keys, a thirteen mm spanner and the familiar notebook with settings that each operator used to carry are now no longer needed due to the Tool Assistant.’

Rademaker believes that the updated line fits in with developments in the industry. Van Dooren: ‘Baking is a craft, but unfortunately there is less and less interest in this remarkable profession. To us, it seems that knowledge of the bakery sector is disappearing, particularly in industrial bakeries. More and more operators do not have a bakery background or training. Due to lack of knowledge and organization, a lot of things go wrong in the dough processing and the production processes. That costs time and money. We believe that The Universal Pastry Line is a machine that allows the processes to be well organized and the Tool Assistant makes it easy to operate, which also ensures more uniform work between the different bakery employees, and tools are no longer necessary. The Rademaker Technology Centre is used to show the advantages of the latest generation of the Universal Pastry Line, explain how the line works and how quickly it can be set up and used.’

Patisserie to the conveyor belt

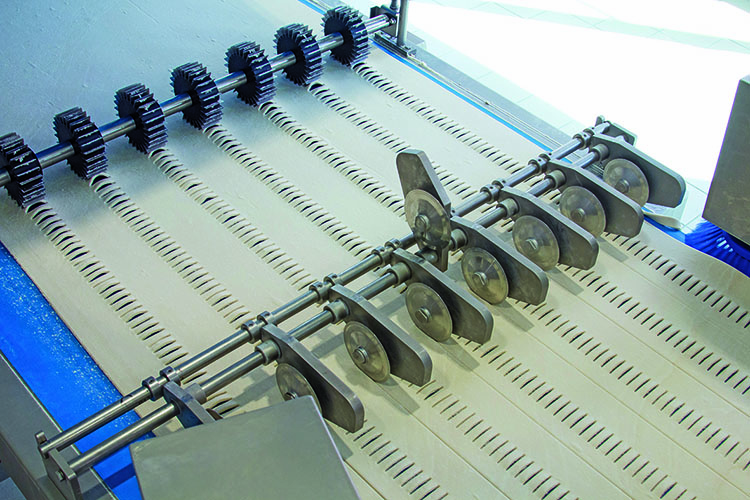

The flexible, modular design of the Universal Pastry Line makes it possible to produce nearly all the various types of viennoiserie and laminated products in many shapes and sizes, filled or unfilled. Rademaker is increasingly moving from being a machine supplier to a system supplier in conjunction with the customer and suppliers of kneaders, proofing cabinets and ingredients. Van Dooren says, ‘Because of this development, the relationship that Rademaker has with customers is changing. We are becoming more of a sparring partner. The process is now also more frequently reversed. While Rademaker merely used to deliver the machine so that the customers could make their product, customers are now asking what they could produce. They are looking for new and different forms. Traditional patisseries and bakers still make a lot of their products by hand. The next step is that experienced technologists increasingly translate this into an industrial process.

It seems that the continuous improvement of machine performance and finding innovative production and end-product solutions will not stop with the launch of the latest generation of the Universal Pastry Line. ‘We have learned a lot from updating this machine line and we will certainly apply that knowledge to other lines. And we will obviously continue listening to customer needs. We enjoy sharing ideas so that they can make high-quality products,’ say De Kroon and Van Dooren.

The main changes

+ Fast and error-free adjustment of the machine

• Settings can be saved digitally per recipe.

• Indication of the direction of the dough on all changeable parts.

• A Tool Assistant makes the operation and adjustment even easier because line configurations and part information can be saved. Information can be exported to the control panel, a tablet or a printer. Pop-up screens explain the settings.

+ Reduction of spillages and wasted ingredients

• The conveyor belts are fifty millimetres wider.

• Because of the previously saved information, non-professional alignment and adjustment of settings are prevented.

+ Improved cleanability

• The new machine meets the highest industrial requirements for hygiene according to the GMA (Grocery Manufacturers Association) standard and EHEDG (European Hygienic Engineering and Design Group) recommendations.

• The conveyor belt can be raised during cleaning so that it dries faster.

• Frames are rounded off.

+ Simplified operation and better ergonomics

• The units are smaller and lighter.

• Parts are fitted with wheels to make them easier to move.

• Each part has a unique number, which reduces

the risk of errors.

+ Reduced maintenance

• Sliding bearers are preferred to roller bearings.

• Direct drive instead of using chains with gears or timing belts.

• Wear and tear of several parts is unavoidable, but all parts last at least six months and can be easily replaced.

Authors

Jan de Kroon is System Architect at Rademaker and in this capacity monitors the content of projects.

Richard van Dooren is Senior Bakery Technologist in the Rademaker Technology Centre in Culemborg. As a very experienced baker and technological expert in different line

concepts, he is an important source of support for the engineers.