By Tobias Fitzel (ttz Bremerhaven), Michael Lütjen (BIBA),

Juan Daniel Arango (BIBA), Michael Freitag (BIBA), Florian Stukenborg (ttz Bremerhaven)

Ensuring constant results from the fermentation process is largely dependent on considering the challenges of working with a living product. Artificial intelligence provides promising opportunities in the flexible management of the process.

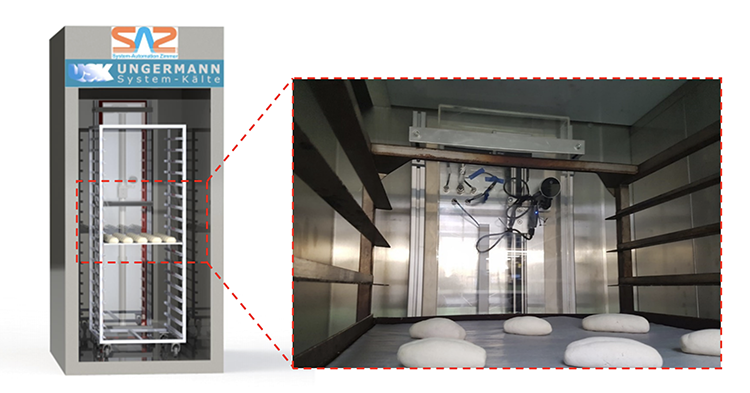

Optimal fermentation control is still a major challenge for bakeries. Due to the use of natural ingredients and changing environmental conditions, the fermentation process requires constant control and monitoring by the baker in order to avoid quality fluctuations. However, control and monitoring are often insufficient, resulting in quality degradation and rejected products. Artificial intelligence and advanced sensor technology in the fermentation machine provide a promising solution to this problem (Figure 1). Provided that the use of sensors pays off from an economic and technical point of view, artificial intelligence (AI) can be used to develop a robust and powerful monitoring system in most quality assurance applications.

As part of a ZIM project (Central Innovation Program for SMEs) funded by the German Federal Ministry for Economic Affairs and Energy ‘FIT IGVA’, a real-time monitoring system based on an extended laser sensor system was developed and tested by Wolfram Ungermann Systemkälte GmbH & Co KG with its partners BIBA – Bremer Institut für Produktion und Logistik GmbH, System-Automation Zimmer GmbH and Technologie-Transfer-Zentrum Bremerhaven (ttz Bremerhaven).

The problem of optimal fermentation control

In industrial bakery production, baking experts spend a lot of time determining the optimum fermentation state. A high level of expertise is necessary especially because the main component, flour, is a natural product. Flour varies in its specific composition depending on the growing conditions (weather, soil conditions, storage period, etc.) and leads to strongly fluctuating fermentation and baking properties of the products. Besides raw material properties, local deviations from the fermentation and cooling parameters (temperature and humidity), e.g. caused by flow changes, can also lead to deviations from the intended fermentation process (Figure 2). These local deviations must be anticipated in the fermentation control in order to stabilize the process by adjusting parameters and ensuring high quality of the fermentation and baking results.

The optimum fermentation state is often hardly feasible to be achieved based on time and fermentation parameters as well as cooling parameters. This applies to subsidiary bakeries and industrial operations. Apart from raw material quality, disturbances in production processes are responsible for this, for example, short line stops or distractions in the operation of a subsidiary bakery, which lead to delays. Fluctuations in ambient conditions such as temperature and humidity during the course of the day can also affect production. Likewise, changes in dough quality (through water addition or kneading intensity), often made for the benefit of better workability/machinability of doughs, can also affect fermentation characteristics. Therefore, the fermentation process must be monitored by qualified personnel and adjusted correctly to obtain good product quality.

Currently, no fermentation system on the market captures the actual state of the fermented product (shape, volume development and surface properties) and gives alarm messages in case of deviations from the ‘optimal’ fermentation point. However, such a process monitoring system would be extremely helpful for an economic and quality-optimized production against the background of skilled workers shortage.

Figure 2 shows the basic flow mechanics in the empty fermentation chamber and the fermentation chamber equipped with a tray trolley. The empty chamber results in a recirculating airflow. The air is led to the floor area after passing through the evaporator on the right side of the wall. The air then flows essentially over the floor and is led or sucked back up to the fan and passed again to the evaporator on the left side of the wall. If a trolley with trays is placed in the fermentation chamber, the air flows mainly around the trolley. Very low and unevenly distributed flow velocities are present inside the trolley. Experimental flow measurements in the day-to-day operation confirmed that there is very little to no air movement between the individual trays. This can have a negative influence on the fermentation behavior, for example, unevenly distributed increase of volume of dough pieces on the tray (from the outside to the inside).

Creation of an intelligent fermentation system

For the creation of the prototype, an existing fermentation chamber from the company Ungermann was equipped with the necessary devices for monitoring the fermentation process. A key element was a LiDAR camera for 3D measurement of the dough piece’s size changes during the fermentation process using precise laser technology. With the high-precision depth sensing of the small form factor and up to 1024×768 Pixels, the LiDAR camera allows 3D information to be captured and stored in the form of 3D point clouds. The LiDAR camera was equipped with a linear actuator on the Z-axis and installed on the rear wall of the fermentation chamber. By moving on the Z-axis, images and point clouds are taken for all the trays to obtain a complete picture of the quality of the doughs placed on the trolley. The LiDAR camera and the linear drive were covered with a hermetically sealed and transparent plastic cover in compliance with food regulations.

The camera data processing is decentralized in the automatic fermenter using a Raspberry Pi 4 as a low-cost single-board computer. The challenge was to develop powerful AI algorithms for complex 3D point clouds on limited computing resources. The development goal here was to detect robustly the dough pieces in the point cloud and measure accurately the individual dough pieces. For the measurement, an approach was chosen, which fits an ellipsoid into the point cloud as optimally as possible. Figure 3 shows in green the result of the dough piece detection on a sheet of a dough trolley. The volume, width, and length of each dough piece are stored.

Figure 3: Detected doughs from a Pointcloud using Ellipsoid-Fitting and volume correction.

Evaluation of the monitoring system

The total time required by the LiDAR camera to completely capture the trays of a trolley is about two minutes. This means that the size changes of the dough pieces can be observed with a maximum resolution of two minutes. At the end of a run, the average height and width of all dough pieces are taken and displayed in a diagram (Figure 4). For deviation detection, a reference curve of the fermentation process for the respective dough is recorded once by the operator. The system can thus also detect outliers, for example, dough pieces that are too small or too large compared to the rest.

Regarding human-technology interaction, this intelligent fermentation device is designed as a process monitoring system that informs the baker about the current status and alerts him in the event of significant deviations. The actual fermentation control process remains in the hands of the baker through the adjustment of humidity and temperature. The automatic fermentation device was designed to work with elliptical dough pieces and recognizes them without error. In a subsequent development stage, other dough piece shapes (pretzels, croissants, etc.) will be implemented.

Figure 4: The results of an hour-long fermentation process. Top: Width and height change over time (blue) and reference curve (red). Bottom: Width/height ratio change over time and volume development over time (each blue) and reference curve (each red).

Artificial intelligence for every application

The combination of sensor technology and artificial intelligence in the Industry 4.0 concept always promises good results whenever the evaluation of the sensor data shows complex correlations, which can be hardly analyzed by pure statistics. In some AI cases, less expensive sensors can be used, which measure properties only indirectly or less accurately but in a network, and can still be evaluated with good accuracy and robustness.

In the present paper, an AI-based process monitoring system for fermentation control was successfully developed, which enables the continuous analysis of the dough pieces with outstanding robustness. The system allows for easily recording a fermentation curve to control future fermentation processes containing the same product. Deviations are quickly displayed within tolerance fields, and, if necessary, alarms are given for manual intervention. In principle, further automation of the fermentation process could help to reduce the shortage of skilled workers in the bakery industry. With this in mind, the partners are working on concepts to realize the (partially) automated intervention utilizing high-performance human-technology interaction. The premise here is that the baker intervenes significantly less often himself but remains the ‘master of the process’ and can use simple guidelines to teach the AI-based system.