+ Conventional fine baked goods such as cakes, muffins and brioche are traditionally made with animal-based ingredients like egg, milk or butter. Replacing those ingredients is directly linked to poor product performance: the crumb texture will lack cohesion and elasticity, resulting in unstable, crumbly products with low volume and deficits in taste and appearance. Developing vegan bakery products requires a good understanding of the functionality of animal-based ingredients in fine bakery wares. Several functionalities of egg or milk products, such as emulsifying, foaming, texturizing and stabilizing properties, must be provided by other ingredients in order to achieve excellent vegan products without compromising the texture or sensory profile. Furthermore, the ability to use established production processes is important for bakery manufacturers, because they will not need to make any major changes to produce these vegan solutions. At the same time, the challenge is to offer solutions that will allow manufacturers to produce vegan solutions economically.

Cyclodextrins for vegan cakes

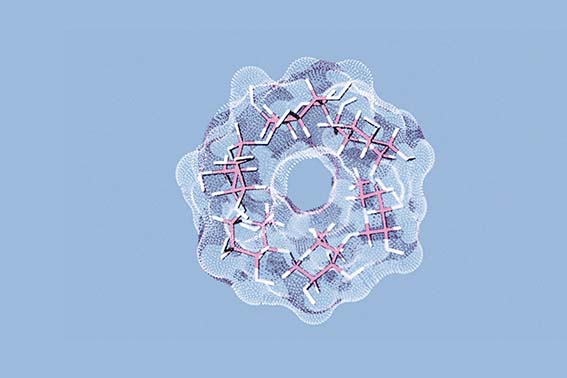

A functional ingredient that can also be found in nature provides the solution to replacing eggs in vegan baked goods: Alpha-Cyclodextrin, an oligosaccharide derived from starch. It consists of six glucose molecules linked together to form a ring. The secret of cyclodextrins lies in their unique molecular structure, a donut-like shape. The exterior shell of the molecule is hydrophilic (water-soluble) on the one hand, while the inner cavity, on the other hand, is lipophilic (fat-soluble). This structure enables the cyclodextrin to interact with lipophilic components like residual fatty acids from triglycerides. The resulting cyclodextrin-triglyceride complex exhibits excellent ‘in situ’ emulsifying properties and stabilizes the oil in the batter – a job usually performed by the lecithin in egg yolk, which stabilizes the batter in conventional fine baked goods and ensures an even distribution of fat.

CAVAMAX® W6 developed by WACKER can be used for egg-free or vegan baked goods to provide excellent crumb texture, volume and a taste profile similar to that obtained with the animal-based counterparts. It is a water-soluble dietary fiber with no taste or odor of its own. The free-flowing white powder can be easily dosed together with dry bakery compounds and it does not require major adjustments when including it in existing production processes.

Beyond its emulsification properties, this Alpha-Cyclodextrin also improves cake crumb texture by interacting with other ingredients of the batter such as proteins and carbohydrates. The usage of cyclodextrin significantly increases cake crumb cohesion and elasticity and ensures adequate crumb firmness, which has a clearly noticeable positive effect on the sensory characteristics of the final baked good. Due to its multifunctionality, CAVAMAX® W6 can be used for partial or total egg replacement in combination with either whey protein concentrates or plant-based protein sources. It is suitable for many applications such as pound cake, sponge cake, muffins and sweet dough products.

WACKER produces the oligosaccharide at its site in Eddyville, Iowa, via an enzymatic process that converts plant starch to cyclodextrins. The site began producing cyclodextrins in 1999, and development has been proceeding steadily ever since.

Utilization

Several formulation guidelines for egg-free and vegan baked goods have been developed in WACKER’s food labs. In muffins, pound cake or brioche, the combination of CAVAMAX® W6, protein and water can completely replace egg or the animal-based ingredients normally found in those products. In a vegan muffin formulation tested by WACKER, the Alpha-Cyclodextrin is combined with almond or pea protein, for example. Water and oil levels have to be adjusted to achieve the desired batter properties. Adding hydrocolloids to work together with CAVAMAX® W6 will help to further finetune product performance.

Vegan dough conditioners: L-cysteine

To standardize the flour and improve the dough’s processability, flours can be treated with enzymes, oxidants or reducing agents like cysteine. The use of L-cysteine is especially common in strong flours, where it reduces the disulfide bonds of the gluten network to weaken it. This results in a softer dough with lower viscoelastic properties, greater extensibility and improved workability. Extensibility and reproducible stretchability are key parameters for tortilla and pizza dough processing, which are becoming more and more industrialized. In addition, proper elasticity is needed to prevent these products from shrinking or curling after they are shaped. Improving dough extensibility with cysteine is also valuable for numerous other yeast and chemically leavened applications, including cookies, saltines and other crackers. L-cysteine as a dough conditioner helps the baking industry optimize the throughput of its baking lines. It improves machinability and may therefore reduce mixing as well as proofing times, while providing uniform and standardized products.

The amino-acid cysteine is traditionally obtained from human or animal sources such as hair, feathers or pig bristles with the help of hydrochloric acid. For decades, there had been no substitute for it. WACKER was the first to introduce a plant-based vegan alternative: the FERMOPURE® L-cysteine, which is based on a fermentation process with an extremely low environmental impact. Inorganic source materials and glucose from plant starch are used as raw materials. It is manufactured at WACKER’s fermentation site in León, Spain. Since FERMOPURE® is manufactured from purely plant-based raw materials, this cysteine is halal, kosher and vegan, making it ideal for all specific dietary requirements.

As an additive in baked goods, cysteine makes it easier to handle and shape the dough, which has several advantages throughout the entire production process. It is particularly important in applications where a specific shape of dough is required, such as croissants, cookies, tortillas or pizza. Highly automated baking facilities benefit from the addition of the amino acid because machines can process the dough properly, resulting in uniform products. In addition, cysteine is of great importance for deep-frozen dough products, as it can partially counteract the negative effects of the freezing process. Furthermore, cysteine increases the gas holding capacity of the dough in the production of toast, buns and baguettes, allowing baked goods to retain their voluminous shape over a longer time and enabling the control of the oven spring. +++

Alpha-cyclodextrin consists of six glucose molecules linked together to form a ring

CAVAMAX® W6 is a water-soluble dietary fiber with no taste or odor of its own. The free-flowing white powder can be used in existing production processes with no need for major adjustments and can easily be added to dry bakery compounds

Under its FERMOPURE® brand, WACKER offers ultrapure cystine and cysteine products made exclusively from plant-based raw materials. Cysteine is commonly used in baked goods, for example