Sweet or savory, pies are a perennial favorite among consumers. Highly specialized production lines are developed to ensure production meets quantity as well as quality needs, efficiently. They are also designed to be operated with ease and safety.

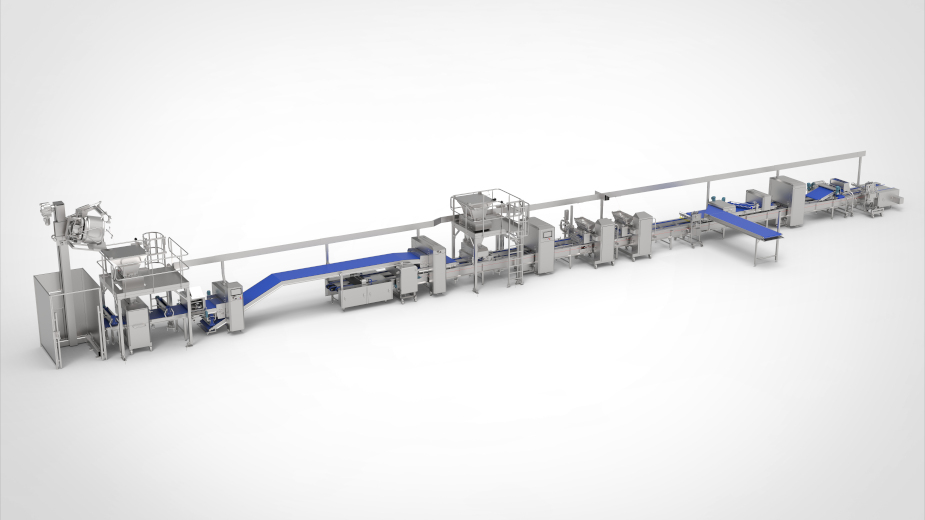

Pie, tart and cake line – Verhoeven Bakery Equipment Family

With BVT’s turnkey line, product variety extends beyond sweet and savory pies, which by themselves make up for a diverse product range, to begin with. The fully automated Pieline can handle all types of pies, tarts and cakes. All kinds of dough can run on this line, from puff pastry to Danish pastry, or shortcrust pastry, yeast dough, and dough for cakes, muffins, and even chiffon cakes, and more. To further add to the possible variety, all kinds of fillings can be combined with the doughs, meaning meat, fish, quiche lorraine, or sweet fillings, to give some examples. Furthermore, all sizes are also on the NPD table with this line, from small forms to full trays. Various shapes are also possible – round, square, or oblong. Lidding the top surface can further extend product variations, as well as lamination.

The capacity of a BVT Pie line extends from approximately 1,000 pieces per hour to more than 45,000 dough pieces per hour. Product sizes can start from 30 grams, and go as high as 2,800 grams.

To optimize the possible process/product combinations with various degrees of automatization, BVT customizes each line to the unique requests of the manufacturers. “Sometimes, we even combine tarts, cakes and pies on one line, from the make-up to the packaging,” Verhoeven Bakery Equipment’s team details. The company designs turnkey solutions that can also include its known vacuum cooling technology. “There are some boundaries to the customizations we can provide, but not many. We can combine different product groups in one line, even with different processes,” they add. An underlying focus throughout the various types of equipment integrated into this industrial line is process automation, so that there would be no manual interference from make-up through to packaging.

BVT can incorporate any depositor from its portfolio onto the Pieline. The company works with the customers to identify the best choice for the particular job, analyzing aspects such as the viscosity of the fillings and desired volume variations.

To fully tailor its turnkey line, BVT offers a comprehensive array of options. Looking at the makeup stage, choices can be made between:

- Paper/tray feeding the forms machine

- Equipment to support different kinds of dough

- Different types of pressing heads

- Different types of depositors

- Rotary molder for the top cover

- Bypass line for the top cover

- Decoration cutters

- Decoration food printers

- Decoration strewers

Handling can also be completely automated: trays are swapped and stored, loaded into the oven and then unloaded, after baking. Automatic depanners are in place, adjusting to the requirements of vastly different products, from pies and cakes to tarts, muffins, or quiches.

Packaging is also included in the BVT turnkey line (BakePack End of Line Solutions), with options for dedicated systems for primary, secondary and tertiary packaging.

“For us, every request is a new request. We reverse engineer the products; so, when you know the end products you want to achieve and the required capacity, we design the lines,” BVT explains.

Vacuum cooling

Vacuum cooling technology is a major component of the Pieline, BVT underlines. “Cooling times can be dramatically reduced; for example, a big apple pie takes around 150 minutes to cool down. With vacuum cooling, this time is brought down to three minutes. Next to the reduced cooling time, energy and time can be saved up to 40% of the oven capacity.” Vacuum cooling also provides better product quality, with optimum organoleptic properties and more volume, compared with conventional cooling, BVT says.

It also has a positive outcome over the shelf-life of the products. This technology also saves precious floor space, as it will occupy, at the most, 20% of the space required by traditional coolers. To optimize operations with this line, it should be regarded as an entity, and not as an assembly of various individual machines, BVT recommends. “An end product is the result of all individual machines throughout the line. Its success is a measure of how well they all work together.”

The article is part of an extended feature on pies, published in Baking+Biscuit International, issue 2 – 2023.

Photo: Pexels (#2693448)