In anticipation of EU regulations setting a timeline and the terms of managing PFAS in manufacturing, consumers and bakers are ready to do without them. Royal Kaak has been working on an innovative PFAS-free coating solution, developed at its facilities in France, that can replace traditional fluoropolymer coatings, with excellent results.

While a segment of coatings free of PFAS has been around for a long time, coating manufacturers have been working on developing advanced solutions in recent years, in search of results that would closely match the excellent qualities of their fluoropolymer counterparts, for general use in bakeries.

Sustainability advances

Royal Kaak has integrated sustainability and climate change mindfulness into its work and solutions it develops for years. “Our vision for the future is Food without Footprint and we strive for integrated production lines that leave no ecological footprint,” says Jordy te Koppele, Business Development Manager. This concept has been driving the Dutch company’s operations and R&D priorities for over a decade. Developments in 3D metal printing and the iBakeCare platform are some of the sustainability-focused solutions in which Kaak has invested. So are advances in finding alternatives to fluoropolymer coatings: “The first and foremost priorities here were health and the environment, but what also emerged was that this coating can be used to bake products differently in our ovens, which also results in a lower footprint during production. In this way, production is not as polluting as when using a fluorpolymer coating,” te Koppele explains.

Ahead of the details regarding a timeline for phasing out PFAS and what the regulation will mean for the baking industry, Royal Kaak has been researching alternatives for PFAS-free coatings extensively. The goal was to provide a solution that was on par with existing coatings in functionality and, importantly, in cost over time, too.

Challenges in removing PFAS

Replicating the non-stick qualities of fluoropolymers is not an easy task. Innovations have been bridging this gap in functionality and in the types of applications where they can be used. But, an important hurdle, perhaps the biggest Kaak observed, was in delivering a comparable lifetime for a PFAS-free coating. In its R&D work, Royal Kaak has been getting closer and closer to that goal. It has been perfecting a solution that compensates for a slightly shorter lifespan (only around 20%, depending on the baking process/product) with lower costs for the new coating. There are no changes to the baking process, no compromises in the quality or variety of the end products.

It’s also worth noting that the number of cycles is not the most accurate means of comparison: the new coating might last slightly less, but it is also cheaper. “The goal is to achieve the same cost per release as with the current coatings,” the specialist underlines. In addition, the utilization also dictates how long a coating will remain intact, whether it’s used for proofing or baking, for products with a hard crust, or for pastries, etc. – an accurate generalization is not straightforward, as pan tracking can only tell one part of the story. The day-and-night difference, however, is in the materials incorporated in the formulation – no substances in the PFAS family were used in the making of the new coating.

A reliable solution emerges

It has been an extensive development project: “We focused on the properties that really matter in industrial bakery environments. One of the most important properties is a low coefficient of friction, which ensures a smooth release and less accumulation of dirt. Another key topic is the high abrasion resistance; this is essential for pans where a hard crust is scraped off 10 times a day and is constantly used in abrasive conditions. In addition, temperature resistance ensures performance under prolonged exposure to high oven temperatures, while chemical resistance provides protection against cleaning agents and other substances used in the production process. This combination makes the coating a reliable and durable choice for bakery production lines,” Jordy te Koppele explains.

Testing also included robotic water scoring, brushing a coated product carrier and UV resistance to assess how the coating behaves in different production processes. E.g. when in contact with high-pressure water jets and mechanical wear on the coating, simulating years of use.

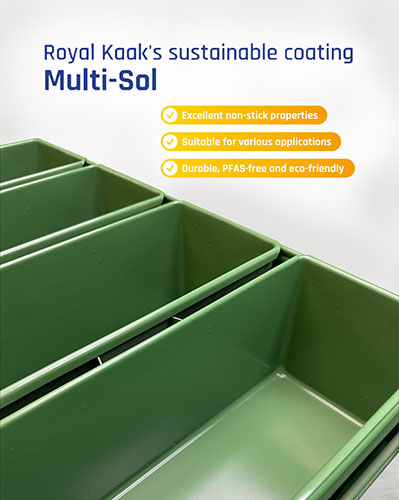

Kaak’s Multi-Sol coating checked all testing boxes with flying colors. Made only with raw materials that do not contain any of the substances listed on the PFAS restriction lists published by the European Union, the formulation was made in strict compliance with the regulations. Furthermore, material suppliers were thoroughly screened and documented, to guarantee the PFAS-free claim.

”Our customers are enthusiastic after using this new coating; in fact, several customers who started testing with this new coating then converted their complete set, or the product for which they had the best results. Despite the usual need for time and a mental shift to accept new innovations, the response was remarkably positive.”

Jordy te Koppele, Business Development Manager, Royal Kaak

The coating performs very well in day-to-day use, with no changes in the regular processing and handling. Its functionality is optimized when used in combination with a release agent or greasing product – although it is not mandatory to include them in order to use bakeware with this coating reliably. The specialist explains: “When switching to PFAS-free coatings, the use of release agents is indeed a concern. This is why we not only developed a sustainable coating, but also entered into a strategic partnership with Dübör, the specialist in release agents and grease application systems. By using a smart greasing machine, the consumption of release agents can be greatly reduced. Practice shows that, if applied properly, the extra costs are minimal and are more than offset by the benefits in terms of food safety, sustainability and longer life of baking pans.”

It can be used to bake anything from cake to tin bread or pizza, as well as frozen goods and greasy products, testing has shown. Moreover, some early adopters are already using the coating in production. From bakeries that are testing a few product ranges or types of trays to companies that have already replaced their entire stock of bakeware with PFAS-free coating – coatings have been replaced on both straps with pans and flat baking trays, even before the switch becomes mandatory. In the Netherlands, even supermarket bakeries are demanding PFAS-free alternatives, te Koppele notes.

Kaak offers guidance for the utilization of coated product carriers, which becomes more actual again when implementing a new type of coating. Since it can be counterproductive to swap the entire portfolio in one move, testing on one line (under normal production settings) is a good way to start validating this new solution.

From Kaak’s experience, European bakeries are already transitioning: “Our customers are enthusiastic after using this new coating; in fact, several customers who started testing with this new coating then converted their complete set, or the product for which they had the best results. Despite the usual need for time and a mental shift to accept new innovations, the response was remarkably positive,” te Koppele shares. Kaak Coating Service has also developed its own process for recoating, to anticipate future needs.

Research makes perfect

The growing interest in PFAS-free coatings is not only driven by upcoming EU legislation, but mainly by the need to answer increased awareness around health and environmental safety. Managing coating compounds is only an aspect of a broader wave of changes, all meant to improve sustainability.

For Royal Kaak Bakeware and Royal Kaak Coating Service specialists, PFAS-free coatings are an ongoing project, after the newly released solution. And, beyond that, the company provides support on any related processes, from compatible greasing systems, to automated washing solutions, up to consultancy on the entire process chain, for improvements. Jordy te Koppele emphasizes: “The demand is shifting from a product-based approach to a partnership-based model to help bakeries optimize their operational efficiency.” It’s an open dialogue that benefits both solution development and production planning.

Per- and polyfluoroalkyl substances (PFAS)

Per- and polyfluoroalkyl substances (PFAS) are a large class of thousands of synthetic chemicals that are used throughout society. However, they are increasingly detected as environmental pollutants and some are linked to negative effects on human health.

They all contain carbon-fluorine bonds, which are one of the strongest chemical bonds in organic chemistry. This means that they resist degradation when used and also in the environment. Most PFAS are also easily transported in the environment covering long distances away from the source of their release.

PFAS have been frequently observed to contaminate groundwater, surface water and soil. Cleaning up polluted sites is technically difficult and costly. If releases continue, they will continue to accumulate in the environment, drinking water and food.

PFAS awareness

Everyone in the Netherlands has various types of PFAS in their blood, in amounts that exceed health-based guidance values in most cases, according to measurements from blood samples from the population, taken between 2016 and 2017. This is the result of a year-long study carried out by the National Institute for Public Health and the Environment (RIVM), an agency of the Netherlands Ministry of Health, Welfare and Sport.

RIVM examined 28 different PFAS in nearly 1,500 blood samples, for a quantitative study that would help form a reliable overview. “At least seven different types of PFAS were found in almost all samples (PFOA, PFNA, PFDA, PFUnDA, PFHxS, PFHpS and PFOS). Five of the substances tested were not detected in any of the samples. PFOS was the most commonly found PFAS in the blood, followed by PFOA,” RVIM announced the results of its research. The organization is now testing samples from 2025, to understand if the measures taken to reduce the population’s exposure have had the intended effect.

The topic has received widespread media attention recently, with this study bringing a new, detailed outlook of the Netherlands. Elsewhere in Europe, other studies show a similar reality: perfluorooctane sulfonate (PFOS), for instance, is widespread throughout European waters, often exceeding regulatory threshold levels set to avoid potential risk to human health and the environment, according to data from the European Environment Agency at the end of 2024. Implementation of EU-wide regulation is being drafted for actionable measures to define a more sustainable manufacturing industry.