Small specialties, from adventurous buns to decadent croissants, are undisputed royalty in the realm of baked goods. Innovation is here to provide the appropriate courtesy while perfecting each batch, consistently.

‘Wildly inventive’ is the year’s top flavor trend, setting the stage for bold and surprising combinations. Dessert hybrids are, perhaps, the most exciting product category reflecting the trend coined by Innova. Experimentation brings creative bakers and curious consumers together: successful new launches such as sweet-and-savory combinations, or unusual creations and limited editions are proof of this. Growing trends include cruffins and crookies, cronuts and biskies, the market researcher illustrates.

Automation and craftsmanship

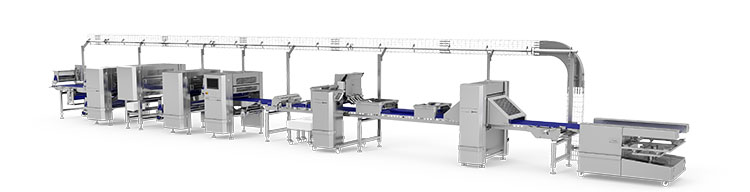

Creativity needs to be met with flexible technology support to bring this level of excitement to market. FRITSCH has been working on developing exactly such a solution. This spring, the company from the MULTIVAC Group launched a new, flexible semi-industrial line dedicated to pastries. Key design features initially introduced with the namesake bread line are now geared toward pastry production. With hygienic design being an equally important priority in any bakery, PROGRESSA Pastry’s architecture prioritizes smooth surfaces and rounded corners to prevent dust from depositing. Because the line is designed for wet cleaning, it means an extensive range or products, sweet or savory, can be made, while ensuring sanitation and safety between production runs.

The line’s capacity is relative to the type of pastry being made. Taking into account the belt speed and the corresponding cutting length, a 4-row production line can produce 12,000 folded Danish pockets per hour, or up to 6,000 Danish swirls per hour, FRITSCH illustrates. It should be noted that the guillotine cuts with a maximum performance of 100 strokes/minute.

FRITSCH aimed to provide the option to produce a great variety of different products on a line that occupies as little space as possible – all priorities at the top of the list in semi-automated operations. Designed to be easy to operate and manage, the new line is modular and comes with user-

friendly controls and various accessories for different products. With a new folding plough concept and an easy-to-remove, substantially lighter wrapping roller, the PROGRESSA pastry ensures easy handling and fast line changeovers. The specialists explain the benefits of the new folding plough system: “One frame can be used for a variety of product configurations, and only one shaft is needed for each product. The folding ploughs can be put on and removed quickly and can be adjusted easily for high production reliability. The folding ploughs can be stored on a frame and put into the dishwasher for fast and easy cleaning.”

Since the line is modular, it can be adapted to any product combination using additional equipment from a line-up including the folding plough system, coiling-in rollers, decorating rollers, moistening units, strewing units, filling units (for spot, strip, or continuous filling), or retracting units.

It also offers the option to build on its initial setup as needed, by adding more automation features over time. Various options are available for automating dough sheet production. The line can be fed with dough blocks on the DOUGHLINER or with a complete laminating line with automated dough sheet production. “For example, a customer might start with a make-up line and add a laminating line later for automatic dough sheet production,” FRITSCH explains. The line can accommodate a wide range of pastry products, from folded Danish products to swirls to special products like Danish plaits. The new hygienic DOUGHLINER or LAMINATOR can also be combined with a MULTIFLEX L, to add croissants into production, in addition to pastries.

”With the new PROGRESSA pastry, FRITSCH is consistently continuing the path started with the new IMPRESSA bread and PROGRESSA bread. Key design features are now available to the pastry segment, placing particular emphasis on good accessibility, quick cleaning and easy handling of the line.”

Stefan Praller, Senior Director Customer Experience,

FRITSCH

Not just the line, but the downstream process can be flexibly adjusted to match it. FRITSCH can offer different solutions for product depositing. “Our latest solution is a very compact retracting unit with single or double tray support, depending on the capacity,” highlights Stefan Praller, Senior Director Customer Experience.

Changing between products running on the line starts with swapping the cutting tools in the guillotine. However, reducing the weight of individual components is also very important. “For example, the decorating rollers and the coiling-in roller are now also available in plastic, making them significantly lighter and easier to handle,” FRITSCH explains. With the new longitudinal cutting unit with free-running cutting knives, a single knife can be swivelled or removed individually for the highest flexibility and quick changeovers.

Automation and craftsmanship don’t need to be mutually exclusive. With this system, they support each other. “With the new PROGRESSA pastry, FRITSCH is consistently continuing the path started with the new IMPRESSA bread and PROGRESSA bread. Key design features are now available to the pastry segment, placing particular emphasis on good accessibility, quick cleaning and easy handling of the line,” Praller underlines.

Ease of use also means that not many users are needed to run the line. In fact, with the new Beckhoff control, the PROGRESSA pastry can be controlled by one person. All inputs are done on one central control panel, for the line and for the accessories – no additional panels are needed on the filling unit, depositing unit, or the coiling unit.

Hygiene is a must-have

The PROGRESSA pastry is designed with sanitation in mind, following the FRITSCH HCD specifications (Hydro Cleaning Design). The hygienic design of individual components includes consistent use of smooth surfaces, watertight covers on threaded connections, and rounded corners where no dirt can accumulate. Fold-up knife edges, like those on the infeed table of the satellite head, for example, ensure good accessibility even in relatively tight spaces. On the so-called ‘omega drives’, the belt can be completely relaxed in a matter of seconds, which makes cleaning under belts a quick and easy process as well, FRISCH highlights. In addition, scrapers for belts and rollers can be folded and/or removed.

The PROGRESSA pastry can be washed down with food-grade cleaning agents at a low pressure of up to 15 bar and a maximum temperature of 60°C (140°F). The hoppers of flour dusters can be removed easily for cleaning. Additionally, the brush of the flour duster can also be easily removed for cleaning, without any tools.

Mobile components, including the filling unit MULTIFILLER S – which is essential in pastry-making, can also be washed down from all sides and allow thorough cleaning in the washing hall. Moreover, the new, easy-to-adjust spreading ruler is suitable for dishwashers.

FRITSCH highlights further hygiene improvements: “The torpedo of the new coiling-in roller (for the production of Danish swirls) is now easy to remove and can be put into the dishwasher.” In addition, the round belt drive eliminates the need for a protective cover, which further improves the accessibility for cleaning.