Numerous exhibitors will present their innovations in Munich. The editors submit a couple of novelties to give trade fair visitors an insight.

New developments

Sollich and Chocotech will be present on a corporate stand and will present new developments. The following exhibits will be shown:

+ A high performance enrobing machine type Enromat® M6-1300 Magnum with a 1,300 mm belt width. The enrober is equipped with one curtain station and one blower unit and diverse accessories. The Enromat® M6 Magnum incorporates high technology when enrobing difficult products with chocolate. A built-in turn shaft with following turnover table allows high performance production of bottom-coated products.

+ Following the Enromat® M6 Magnum is a chocolate cooling tunnel of the Thermo-Flow plus type KSK 1300 with telescopic infeed table. The cooling tunnel is equipped with bottom water cooling and with new gullwing PU-covers for better accessibility of the cooling chamber. The complete installation is equipped with the “Fast Lane” remote control system.

+ An automatic 820 mm Decormatic® type DC4 decorating device installed on a decorating belt and Minitemper® MT 100 to feed the decorating machine. The machine will be on display with chocolate during the exhibition. The various decoration patterns are programmable, i.e. product change can be done very easily.

+ A Turbotemper® type TE 1800 to feed the type Enromat® M6 Magnum enrobing machine. The Turbotemper® includes an automatic Tempermeter type Tempergraph.

+ A Turbotemper® type TT 100 B Airo for small capacities. The TT 100 B Airo is equipped with a heating reservoir tank and a feed pump, especially designed for tempering smaller chocolate capacities in a superior tempering quality. The integrated aeration system allows aeration of the mass.

+ A chocolate coating machine type Minicoater™ MC 420 with 420 mm belt width will be on display with chocolate, followed by a Thermo-Flow® plus cooling tunnel type LSK 420. This machine is running very successfully at small and medium-sized companies setting new standards in the mini enrobing technology sector.

+ A special type CA 820 caramel enrobing machine with an 820 mm belt width for enrobing wafers or biscuits with caramel or – after slight machine adjustment – also with sugar icings.

+ A type KGS 1050 piston depositor to deposit fat masses, jelly or caramel.

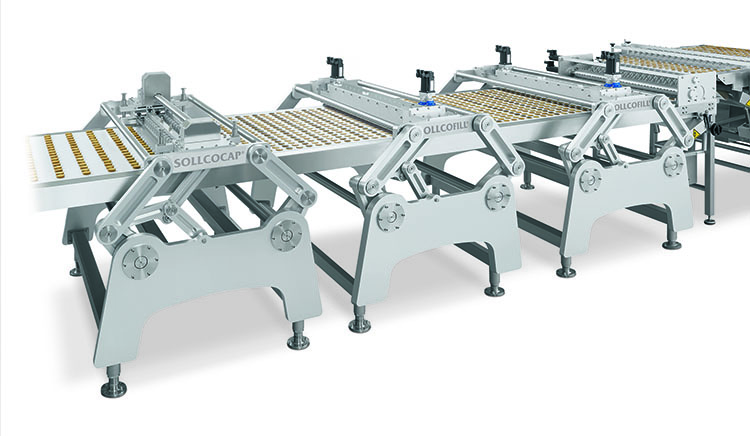

+ A highlight at the iba will be the Sollcofill/Sollcocap depositing line to refine biscuits, e.g. fillings like caramel, fondant, nut paste, jelly, milk or yoghurt cream or chocolate can be deposited together with ingredients. The performance of the system has been greatly increased and guarantees high-quality production of sandwiched products. Products which do not meet the quality demands, e.g. a biscuit that does not match the shape, will be rejected automatically by the machine.

+ The combination of the Sollich machinery together with the Chocotech company’s cooking equipment to produce sugar, jelly or caramel masses allows customers to obtain production responsibility from a single supplier and thus also ensures production lines are commissioned efficiently and as quickly as possible

A highlight at the iba will be the Sollcofill/Sollcocap depositing line for refining biscuits

The article is part of an extended feature, which was originally published in [BBI 5 – 2018]. Read the full article in the magazine: