Middleby Corporation partnered with Vyv to provide baking equipment that comes equipped with antimicrobial LED technology, a continuous hygiene solution based on UV-free, visible light that safely offers protection against bacteria, viruses, mold, fungi, yeasts and other microorganisms.

Middleby announced the investment and license agreement with Vyv in 2021, with the goal of creating cleaner food processing environments by combining their technologies. Vyv started with the goal of making healthcare environments cleaner, but has broadened its portfolio of antimicrobial lighting solutions that lower microbial counts on surfaces in a wide range of commercial and industrial environments and applications. These are LED-based lights and do not contain bulbs or other consumable parts and are warranted for five years. The technology brings notable added benefits, too: it is energy-efficient and environmentally sustainable as it continuously works to prevent microbial growth indoors. In addition to cleaner surfaces, Vyv’s clients have reported significant reductions in air contamination. All of these are highly sought-after in bakery production facilities, where they can now be incorporated into Middleby equipment.

Antimicrobial lighting works so efficiently and precisely because it never stops, unlike traditional disinfection methods, which allow germs to reenter the space as soon as the cleaning has finished. Vyv’s technology works non-stop and in between routine cleaning times and addresses all challenges commonly associated with food production environments, from mold, to listeria, salmonella and other food-borne organisms, while preventing the formation of biofilms. Several bakeries are convinced by the technology and are now already running it, both in the overhead lighting of production facilities and in areas prone to microbial development such as proofing and conveying. They were able to validate the microbial reductions they achieved, with measurable results. Potential uses that can benefit baking production facilities do not stop here; the company is exploring implementation into automated guided vehicles, which are increasingly present in industrial baking.

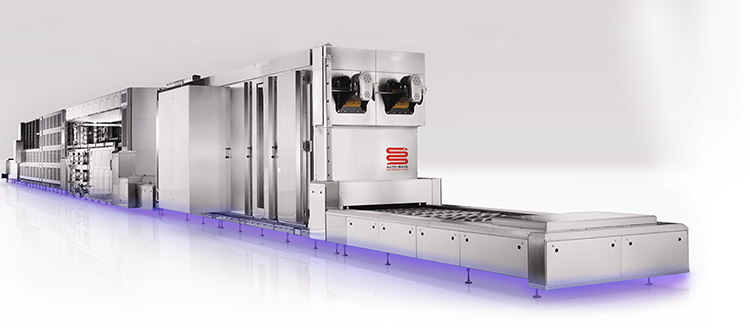

Scott McCally, Auto-Bake Serpentine President, underlines the value of this solution: “The key message is in the immediate impact this solution will have, starting with uptime. If you lower the time spent sanitizing, you gain production time, which is especially valuable in bakery. Mold is inherent to what we do; if we can reduce mold, we can extend shelf life, which is another immediate benefit. And, with cleaning better managed, less water is needed, which brings down operating costs while production rates goes up.”

Each light, regardless of the mechanical housing specification, is designed to deliver the needed dosage for the space. Kristin May, Vyv’s Chief Commercial Operations Officer, states the company will support individual installation needs: “Vyv’s antimicrobial lights look, feel and act just like a standard light. Vyv’s specialists will work with the client’s facilities team to review existing lighting and requirements to recommend the type of replacement light.” This antimicrobial lighting includes a vast range of specifications, starting with general-use luminaires to specification grade IP69 (the highest Ingress Protection tier), and NSF-rated luminaires (suitable for use in food-preparation facilities). These lights include both modes of operation, Antimicrobial+

Light and Enhanced Antimicrobial, the company explains:

+ Antimicrobial+Light mode delivers high-quality white light for illumination and antimicrobial action at the same time. As this type of light can be used around the clock, it can entirely replace conventional overhead lighting. While working continuously against germs, it can be installed in any type of facility, from production spaces to commercial areas and offices. No specialist technicians are required to install the overhead lighting systems and fixtures.

+ Enhanced Antimicrobial mode delivers a violet hue with an even higher dosage of antimicrobial light, used when illumination is not needed. For example, in between shifts, this mode can be switched on for even faster germ-killing action with a visible violet hue (non-UV). It was developed specifically to address hard-to-reach spaces, such as under equipment or within conveyor belts. Vyv’s Antimicrobial Light Bar can be designed onto new equipment or installed on existing machines. A working AutoBake oven featuring this deep-cleaning, violet light made its debut at IBIE this year, where it received top honors in the sanitation category.

Tried and tested technology

The company explains how this technology is designed for continuous and unrestricted use around people: “Vyv’s antimicrobial technology harnesses specific wavelengths of visible light that target molecules exclusively found within microbes and problematic spoilage organisms. This ultimately creates an inhospitable environment for viruses, bacteria, mold, yeast, and fungi. Vyv lights have been tested to IEC photobiological safety standards, and fall into the exempt category, which states that there are no exposure limits and can be used unrestrictedly and continuously around people.” In environments such as a bakery or food production facility, Vyv recommends 24×7 usage for optimal results.

Vyv’s technology has been tested by several independent research and commercial organizations to prove its effectiveness in killing viruses, bacteria and mold. “Our antimicrobial technology has been proven to eliminate 90-99.99% of the surface contamination that occurs within spaces such as a production floor or within/around equipment, without harming the people occupying the space, or the equipment,” Vyv says. The results are dosage-dependent, where dosage comprises an irradiance (power of light hitting the surface) and a time element. The higher the irradiance and the longer the exposure time, the higher percent kill achieved.

Vyv’s clinical efficacy claims are based on ASTM testing. For example, “Laboratory-controlled testing on SARS-CoV-2 (enveloped virus) showed a 98.45% reduction in four hours on hard surfaces. Testing on a non-enveloped virus (MS2 bacteriophage) showed a 97.12% reduction in controlled laboratory testing on hard surfaces in eight hours. Testing on MRSA and E. coli showed 90%+ reduction in controlled laboratory testing on hard surfaces in 24 hours,” Vyv tells us.

Benefits of using antimicrobial lighting in bakery production areas

Sustainability

+ It is a non-chemical solution that cleans continuously, which means that the use of harsh chemicals in the facility can be reduced or entirely eliminated.

+ Antimicrobial light works constantly against the microbes in a space, so less aggressive mitigation is needed overall.

+ It contributes to improving yields, reducing waste and to the shelf-life of products.

+ Vyv’s technology contains no damaging UV light, so it can be used around people and it will not degrade equipment and machinery.

Productivity

+ The improved hygiene helps with labor challenges inherent in spaces that are required to be continuously clean.

+ Vyv’s patented antimicrobial light technology works continuously in the background, to clean surfaces and supplement existing sanitation procedures.

+ Regular cleaning can be done faster and is easier.

Protection

+ This antimicrobial solution helps prevent product recalls and the consequent damage to the brand image.

+ Organizations using this technology can promote their commitment to health and wellness.

+ Vyv meets international standards for unrestricted and continuous use around people.

Bluezone

Middleby also provides Bluezone, a patented technology for indoor air purification, which it provides via an exclusive licensing agreement with an investment in Bluezone Products Inc. This no-filter air purification system destroys 99.9995% of viruses and other indoor contaminants such as bacteria, mold and gases that impact indoor air quality. This means airborne pathogens such as the flu, colds and COVID-19 are eliminated with UV-C germicidal lamps. “Ultraviolet lamps have a long history of sanitizing surfaces in laboratories and food-processing industries and also for disinfecting water supplies. Since the UV-C lamps are locked inside the Bluezone chamber, it is safe to operate 24/7 in occupied spaces to keep your guests and employees safe,” Middleby explains. The Bluezone system works by pulling air into a chamber, where it is scrubbed with an ultraviolet germicidal light process that destroys a virus’ RNA. This eliminates its ability to replicate.

Bluzone’s UV-C bulbs kill up to 99.9995% of viruses in the air, including colds, flu and COVID, model sizes treating from 4,000 ft3 (113 m3) up to 15,000 ft3 (425 m3) per chamber with 30-150 CFM flow rate (cubic feet per minute) circulating the air quickly and continuously killing airborne viruses in dining and working spaces. Furthermore, oxidation catalysts destroy volatile organic compounds (VOCs) and unpleasant odors, adds Middleby. How does it do all this? “The Bluezone by Middleby Viral Kill models utilize enhanced UV irradiation around 254nm, optimized for destroying viruses in occupied spaces,” the company explains. The UV radiation over time, coupled with the flow rate through Bluezone’s reaction chamber, results in a log five kill rate for the MS2 (SARS-CoV-2 Surrogate) virus, Middleby points out. The Viral Kill unit also features a room-temperature oxidation catalyst to convert VOCs into CO2 and H2O.

After the initial investment in this unit, the only requirement is to change the bulbs roughly once a year, Middleby points out. “No more switching out filters every few weeks. Plus, the unit lets you know when a new bulb is needed, eliminating the guesswork.” Bluzone is also safe to use in spaces with people coming within its reach, as it received clearance as a Class II medical device from the Food and Drug Administration (FDA) based on clinical data that demonstrated efficacy, safety and reliability.

Bluezone comes in model three sizes, with three mounting options: drop-in ceiling, enclosed floor cabinet, and wall shelf mount.

+ Model 300 is a hybrid model for killing viruses in small spaces or keeping refrigeration environments free of damaging contaminants to extend product shelf life and eliminate flavor transfer. This model uses UV-C bulbs to inactivate airborne viruses and disinfect the air. Up to 4,000 ft3 (113 m3) can be treated, at a 30 CFM flow rate. It utilizes a combination of self-contained ultraviolet light and room-temperature oxidation to destroy viruses and VOCs.

+ Model 450 is an air purifier, which also uses UV-C bulbs. It can treat up to 9,000 ft3 (255 m3), with a 150 CFM flow rate circulating the air continuously. Oxidation catalysts destroy VOCs, odors and airborne viruses (including COVID), which makes it beneficial for dining in and working spaces.

+ Model 2400 is designed to keep refrigeration environments contamination-free. For this equipment, UV-enhanced oxidation is used to destroy contaminants such as ethylene, mold, bacteria and odors. It eliminates 99.9% of mold and bacteria, as well as ethylene gas in walk-in refrigerators to extend shelf life and reduce waste, Middleby explains. Ozone-generating UV bulbs use a combination of high levels of ozone and UV to oxidize and irradiate airborne contaminants. Up to 15,000 ft3 (430 m3) can be treated, at a 30 CFM flow rate.

The collaboration

James K. Pool III, Middleby Chief Technology and Operations Officer, shared insights into the collaboration between the companies to provide this solution together: “Partnering with Vyv ensures we will offer the most advanced products in the market to promote the health and wellness of our operators and their customers. [We] are well positioned to deliver cleaner food preparation environments, with an extensive assortment of overhead antimicrobial lighting fixtures for processing plants, commercial kitchens and any foodservice facility.”