New WCX Wirecut Machine from RBS

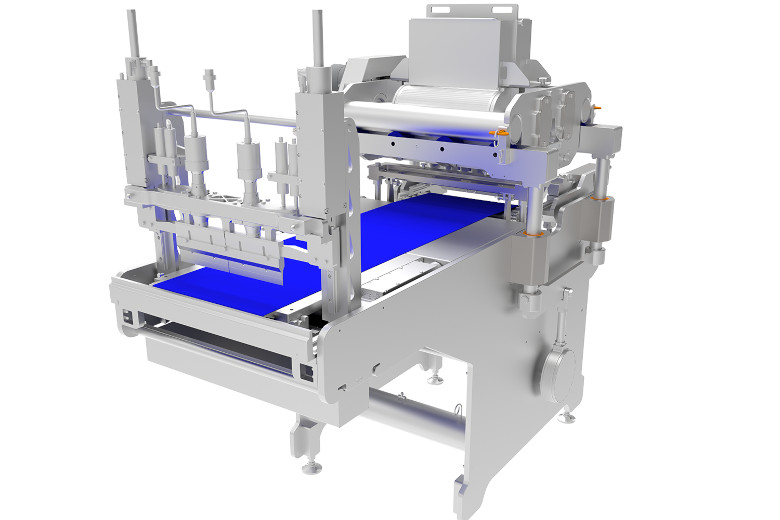

Reading Bakery Systems (RBS) introduced a new advanced Thomas L. Green WCX Wirecut Machine that provides more product flexibility, control, better safety features and easier sanitation than previous designs.

Reading Bakery Systems (RBS) introduced a new advanced Thomas L. Green WCX Wirecut Machine that provides more product flexibility, control, better safety features and easier sanitation than previous designs.

The 2022 Eco Twin model was revised to provide increased performance, options for modular layout and optimization in several process areas.

In April 2022, MULTIVAC Canada opened the first local FRITSCH World of Bakery in Brampton, Ontario. The technology and test center took one year to build and is dedicated to customers from the North and South American markets.

Combining functional and molecular flour analytics will establish a comprehensive picture of the grain, and help to achieve better baking results.

BAKON introduced a new ultrasonic cutting machine, the PICO, designed for operations with smaller production volumes. It can be used for round and rectangular cakes, as well as for triangle-shaped products, in trays, or on cutting boards.

From viennoiserie to Danish pastry, and any number of hybrid, new creations, laminated dough is the path to the sought-after airy, light layers.

Precision and consistency are required to turn blocks of dough into thin, delicate sheets. The big challenge lies in the correct distribution of the dough reduction steps while avoiding any unwanted tension in the dough. Inconsistencies in the reduction steps will significantly impact the structure of the final product.

Lesaffre inaugurated its 48th Baking Center™ in Dubai on November 9, 2021, building its presence in the UAE and the wider GCC region.

As gluten-free bakery is decisively increasing its foothold into the mainstream market, growing by about 25% each year, research seeks to improve product taste, texture and nutritional profiles.

The Rademaker Technology Center (RTC) features several pilot lines, full-scale, certified production lines that meet the latest standards, which are available for testing. The company believes knowledge is an investment worth making, and invest it did: over the past two years, the RTC has been developed to more than twice its starting size, to its current 2,400sqm.

The next best thing since sliced bread might just be the technology behind consistency for all types of bread and versatile bagging options for ever-changing requirements.

While the SE Asian bread market was a key focus for the project, from the start it was recognized that the study of dough development through mixing and processing would have wider implications and offer new opportunities for bread-making throughout the world.