Jackson, Michigan-based technology specialist LeMatic has been tackling challenging automation projects in industrial baking. These custom robotic solutions are designed to meet unique production demands, often involving high-speed operations, delicate product handling, and seamless

integration with existing systems.

Modern robotics offers great flexibility, with systems capable of operating from a single axis up to six axes – and even beyond. This range of motion enables an almost infinite number of movements, allowing robots to perform complex tasks with precision and adaptability. From simple linear actions to intricate multi-directional operations, robotic automation brings reliable help on the production floor.

Tailored robotics

LeMatic recommends robots based on the specific needs of each application, including product type, required speed, and payload capacity. Depending on the task, robotic systems can operate at speeds ranging from 10–15 picks per minute to well over 125 picks per minute, per robot. “These performance levels are influenced by factors such as the weight of the product and the complexity of the motion required,” explains Teresa Ruder, Global Business Development Manager, LeMatic. However, successful integration also depends on physical constraints. The specialist points out: “Space limitations may restrict the number of robots that can be deployed, while heavy payloads can lead to overheating, potentially shortening the robot’s lifespan. LeMatic’s engineering team carefully evaluates these variables to ensure optimal performance and longevity in every installation.”

IoT technology makes these robots intelligent and easy to integrate. The equipment can communicate directly with a bakery’s ERP (Enterprise Resource Planning) or MES (Manufacturing Execution System), establishing a real-time data exchange. There are several benefits to this, from smarter decision-making, improved traceability, and streamlined operations.

Software also helps customize the selected robots according to the operations needed and the products handled. Incorporating intelligent automation, LeMatic’s AutoEye line of vision systems can be tailored to ensure quality, collect product data, and monitor critical points throughout the production process. LeMatic illustrates: “In one application, AutoEye was deployed at the product infeed to measure the diameter of each item in real time. This data was instantly communicated to the robotic system, which then adjusted its pick and place locations based on the product size. The program was fully customized to accommodate varying product dimensions – ensuring seamless operation even with frequent size changes.”

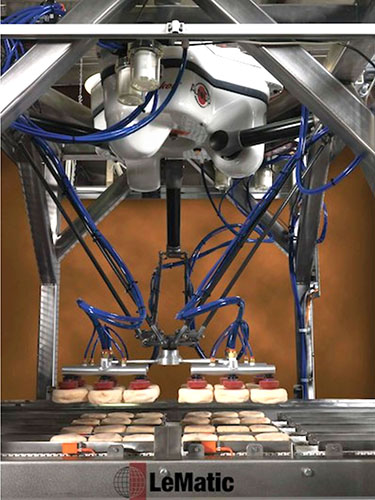

For hardware customization, these robotic systems feature customized end-of-arm tooling designed to handle products with care, whether picking, placing, or moving items. Robotic tooling systems are selected based on the specific demands of each application, including product type, required speed, payload, and available space. The tool selection process also considers payload limitations (heavier loads may risk overheating and reduce the robot’s lifespan) and spatial constraints, which can affect how many robots can be deployed in a given area. LeMatic focuses on matching the right robotic tool solution to each unique production challenge, with a comprehensive range of models and configurations that can ensure optimal performance, reliability, and longevity. To handle diverse products seamlessly, LeMatic’s robotic systems are equipped with fixtures that allow them to automatically select the appropriate tool for each incoming item. These tools are custom-designed to match the specific requirements of various applications. “Thanks to quick-change technology, robots can efficiently detach and attach tools without manual intervention, maximizing uptime and enabling rapid adaptation to changing production needs,” Ruder highlights.

LeMatic’s new Pattern Loader is also a notable feature for product customization. It allows operators to create and manage various designs directly through a user-friendly HMI interface. “In one facility, a single P7 robot equipped with this technology is handling over 50,000 pieces per hour,” LeMatic highlights.

Smart is the new automation

New developments for next-gen robotics dedicated to high-volume baking automation prioritize speed, accuracy and adaptability. The latest developments in the field include features that make robotic systems smarter, more flexible, and easier to operate. LeMatic is including new features such as:

AI-powered vision and decision-making systems are an instant process upgrade, with their capability to identify any product characteristics needed. “These systems can self-learn and adapt to new products with minimal human input, improving accuracy and reducing false rejections,” LeMatic highlights.

LeMatic’s robots feature automatic quick-change tooling, allowing them to switch between custom-designed end-of-arm tools based on incoming product data. In this way, changeover downtimes are minimized, to support mixed-

product lines.

New, advanced HMI features enable pattern and recipe management and selection without the need for tool changes. “This streamlines operations and enhances reliability,” LeMatic points out. In addition, AI algorithms also monitor robot performance in real time, which not only ensures productivity, but can also predict maintenance needs before failures occur.

For flexible deployment and mobility, new robotic models, such as Schubert’s tog.519, offer high-speed performance (up to 90 cycles per minute) and can be repositioned easily using simple equipment such as pump trucks. New developments include:

+ Soft-touch end-of-arm tools with auto-adjustment features now allow robots to handle delicate baked goods with greater care, reducing damage and waste.

+ Self-learning capabilities, machine learning algorithms that enable robots to adapt to new tasks and product variations, streamlining setup and reducing programming time.

Custom solutions

The robotic solutions developed by LeMatic are suitable for any area of a bakery where manual labor is currently used, for operations such as repetitive tasks, high-speed sorting, or precision placement. Complex projects where LeMatic robotics can be deployed can include:

+ Multi-product handling with AutoEye integration

In one installation, LeMatic’s AutoEye system was paired with a robotic arm capable of identifying and sorting products of varying sizes and shapes in real time. The robot adjusted its pick-and-place locations dynamically, using AI-driven vision to ensure accuracy and speed – without manual intervention.

+ High-speed pattern loading with custom HMI

LeMatic’s Pattern Loader was deployed in a facility where a single P7 robot handled over 50,000 pieces per hour. The system allowed operators to create and modify product patterns via a user-friendly HMI, enabling rapid changeovers and reducing downtime.

+ Dual-line emergency diversion system

In a plant running two concurrent lines, LeMatic engineered a robotic solution that could instantly divert product from one line to another in the event of a fault or emergency stop. This minimized waste and maintained production continuity.

+ Tool-changing robotics for mixed product lines

For bakeries producing multiple product types, LeMatic developed robots with quick-change tooling systems. These robots automatically selected and swapped custom-designed end-of-arm tools based on incoming product data—ensuring gentle handling and precise placement across a variety of baked goods.

New AI automation tools

Artificial Intelligence (AI) is rapidly transforming the landscape of robotic automation in industrial baking. LeMatic observes more adaptive solutions than ever before and is actively exploring and integrating AI into both existing and upcoming robotic tools to enhance performance, flexibility, and decision-making. “By integrating AI, LeMatic is not just automating tasks – it’s enabling smarter, more responsive production environments that adapt to the needs of modern bakeries,” the specialist says. The company is working on further new features, emerging opportunities for AI applications including:

+ Self-optimizing production lines: AI can analyze production data in real time and adjust robot speed, pattern loading, and rejection criteria to maintain peak efficiency.

+ Labor forecasting and load balancing: AI can help bakeries forecast labor needs and dynamically shift workloads between robotic systems and human teams, LeMatic anticipates.

+ Recipe adaptation and batch customization: future AI tools may allow robots to adjust handling based on recipe changes, seasonal variations, or customer-specific batch requirements.

Smart safety

Smart technology also provides helpful tools for maintaining product quality and operational efficiency. LeMatic’s automation systems are equipped with rejection mechanisms that activate when a product is incorrectly sized or positioned. Rejection can be executed in several ways: the robot itself can remove the item, a retracting conveyor can eject it, or a high-pressure air jet can blow it off the line. For emergencies, the system’s stop functions can halt the entire production line instantly, allowing for immediate intervention. “In facilities running multiple lines concurrently, LeMatic’s systems offer the flexibility to stop one line while seamlessly diverting product flow to another – ensuring minimal downtime and uninterrupted productivity,” the specialist illustrates.

These innovations are making robotic systems more accessible and practical for bakeries of all sizes, helping them overcome labor shortages, improve product quality, and boost overall efficiency, LeMatic underlines.