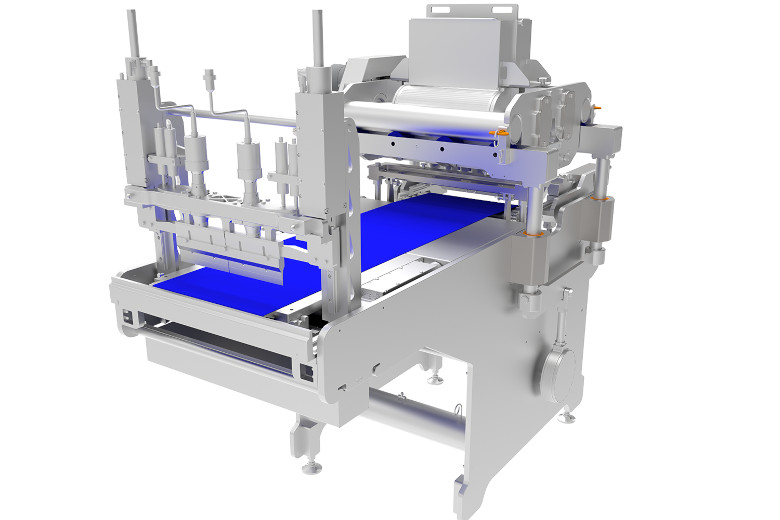

Reading Bakery Systems (RBS) introduced a new Thomas L. Green WCX Wirecut Machine that provides more product flexibility, control, better safety features and easier sanitation than previous designs.

This new machine has an expanded range of product capabilities including standard and filled bars, multi-color products, filled and encapsulated cookies, pet treats, frozen dough applications and more, RBS details. The WCX is capable of producing throughput yields of up to 300 cuts per minute (cpm), with a high degree of accuracy and consistent piece weight.

The new WCX Wirecut Machine uniformly cuts individual shapes with a wireframe assembly. An optional ultrasonic attachment can be used for materials that are more difficult to cut and separate cleanly. The recipe-driven linear servo motors provide an infinite number of cam profiles to control wire positioning, stroke length, drop and up-shoot. Adjustments can easily be made via the integrated touchscreen while the machine is in operation. The unit provides automatic self-timing for wire positioning to the die cup.

Custom-designed die and wirecut assemblies are created for specific product characteristics. The flexible machine offers several ways to co-extrude cookies and bars, and internal and external pump systems can be added for expanded product capabilities. Cutting or crimping of bar products are accommodated by an integrated cutting system mounted after the wirecut machine on the transfer conveyor frame.

“The WCX Wirecut Machine is truly impressive. Our focus on innovation means we’re delivering the maximum in production flexibility and efficiency to our customers,” said Sam Pallottini, Director Cookie, Cracker, and Pet Food Systems Sales.

The new equipment is designed with over 50% fewer parts than standard wirecut machines, which helps with cleaning and maintenance, along with its tool-less product changeover capability. The head is removed from the side of the machine for quick access and sanitation. The design uses common servo motors for improved maintenance and reduced critical spare parts inventory. Wash-down components like dies, filler blocks, wireframes and wirecut heads, are easily removed without tools, RBS explained.

Photo: Reading Bakery Systems