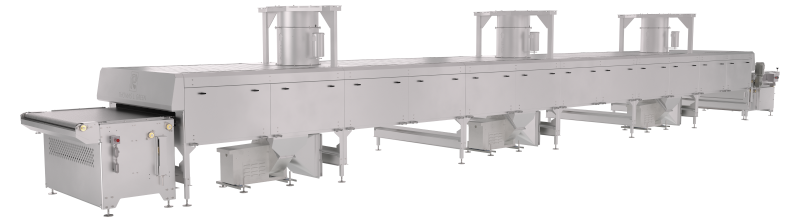

Reading Bakery Systems (RBS) introduced a new ambient cooling conveyor, with increased efficiency in cooling crackers before entering packaging in a more compact footprint. If the crackers are not cooled to the correct temperature, condensation can occur in the sealed package, which compromises snack product texture and shelf life. Final product moisture and temperature

control is critical to success.

“The new Thomas L. Green Ambient Cooling Conveyor design is a win‐win for cracker manufacturers, as it is more efficient to operate and easier to clean and maintain. It also reduces energy consumption, energy waste and employee safety hazards,” said Cameron Johnston, director of engineering, RBS.

The new cooling tunnel system is modular, allowing for multiple sections to be added, according to plant and/or process needs. Each module is equipped with upper and lower fans, each with individual speed controls. Operators can control the amount of air blown across the top and bottom of the crackers via touchscreen control screens.

Additionally, maintenance has been streamlined and made safer, RBS pointed out. Air filtration cartridges can be handled without ladders and can be changed or cleaned without the use of tools. Air handling blowers can be accessed at ground levels, again not requiring ladders.

RBS provides processing solutions for the production of a wide range of snack products, continuous mixing solutions for the food industry and oven profiling. Company brands include Thomas L. Green,

Reading Pretzel, Exact Mixing and Reading Thermal.

Photo: Reading Bakery Systems