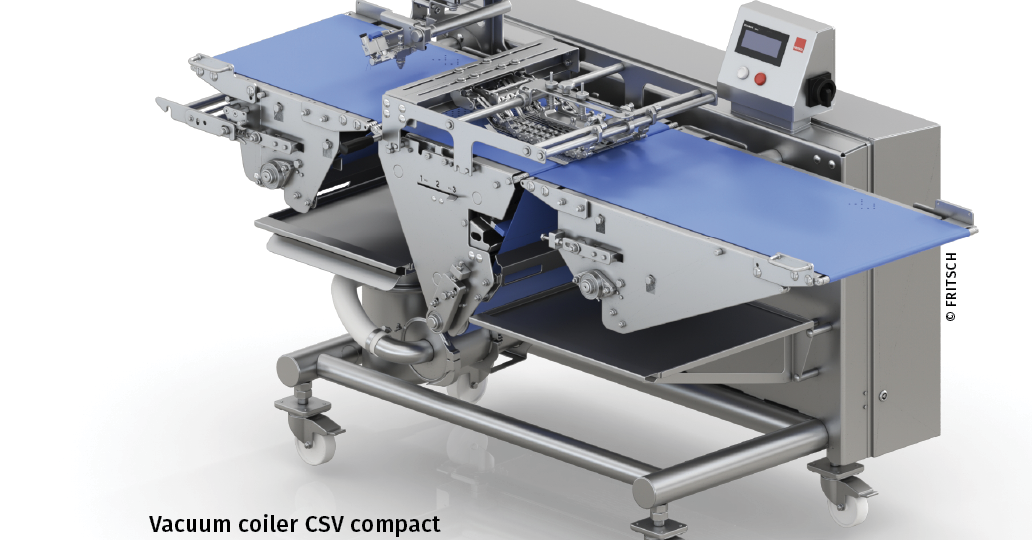

The FRITSCH CSV compact is a vacuum coiler that fixes the dough pieces or the dough pieces cut into triangles on the belt by means of a vacuum, which prevents them from slipping whilst coiling. Ideally, the machine is used downstream of a FRITSCH CTR or a MULTICUT. Both filled and unfilled products, such as croissants, chocolate croissants, various croissants and also pigs in a blanket can be produced on the machine. For the latter, only the coiling cassette and the vacuum template need to be changed. The coiling cassette is placed on the existing locks of the CSV compact. Tools are not required for the product change.

The processes of diapering

1 Fixing the sausage on the dough piece: For this purpose, a motor with a moving belt has been installed. It is located on the coiling cassette and ensures that the sausage is precisely fixed before coiling and can no longer slip.

2 A coiling cassette with a scribing hook grips the piece of dough and the first impact is made so that the sausage starts to rotate.

3 Subsequently, the hooks are released and by means of the coiling mat with the piece of dough remaining in motion. The other windings follow.

The processes of diapering

1 Fixing the sausage on the dough piece: For this purpose, a motor with a moving belt has been installed. It is located on the coiling cassette and ensures that the sausage is precisely fixed before coiling and can no longer slip.

2 A coiling cassette with a scribing hook grips the piece of dough and the first impact is made so that the sausage starts to rotate.

3 Subsequently, the hooks are released and by means of the coiling mat with the piece of dough remaining in motion. The other windings follow.

The most critical process steps

1 The first impact with the scribing hooks: Here the sausage must be brought into rotation in order to be able to carry out the further coiling cleanly and precisely.

2 The transfer of the dough piece after the first wrapping from the cassette with the wrapping hooks and thus the infeed into the coiling mat is another critical step. The seamless transfer of the product must be ensured so that the speed can be transferred to the further rotation of the coiling mat.

The number of coilings

The number of coilings that can be wrapped around the product depends on two factors: the product size and the individual customer requirements. One to three wraps are possible without any problems.

What pressure the product subjected to?

With this coiling system, very little pressure is applied to the product. This is very important; after all, the product should retain its shape. The greater the pressure acting on the sausage, the higher the risk of cavity formation. This must be prevented.

The performance of the coiling cassette

The performance of the sausage coiling cassette is mainly given by the placement of the sausages. The coiling cassette itself manages up to 80 cycles (i.e. rows per min, in industrial lines up to 6-row cassettes are possible). In a semi-automated solution, where the sausages are placed on the dough pieces by hand, the limit is about 60 cycles.

What dough parameters to follow

When using the coiling cassette and making sausages in a dressing gown, the same parameters should be observed as for a croissant. This includes, for example, the correct amount of flour below the dough band. With regard to flour, always use as much flour as necessary, but as little as possible. The best results are obtained with a dough thickness of 2.5-3.8 mm.

Cleaning process

The vacuum coiler is suitable for ‘wash-down’ cleaning, which FRITSCH says ensures fast and thorough cleaning.