Mecatherm will present an entirely newly designed oven at the iba trade fair.

Key advertised features include precision and flexibility.

The French bakery machine constructor Mecatherm has its production facilities in Barembach near Strasbourg. However, drumbeats from the Vosges Mountains will be heard at the iba trade fair. One of these announces an entirely newly designed modular tunnel oven with which Mecatherm is specifically targeting medium-sized bakeries. The businesses in focus are those wanting to process a diverse range of products flexibly but without relinquishing a differentiated heat transfer profile consisting of radiant and convection heat matched to the respective baked goods. The engineers also promise efficient processes and precise control.

This oven is aimed mainly at major chain store businesses and specialty manufacturers in industrialized countries. Here in particular, according to Mecatherm President Olivier Sergent, there has been a large growth in the demand for high-quality variety. He says this is forcing companies towards a more complex, multi-faceted production organization and correspondingly modifiable technology, especially in the baking step of the production process. It is said to be still rather a niche activity at present in other countries, but a thoroughly attractive market due to the purchasing power existing in the middle classes. However, no matter how greatly diversity and an artisan visual appearance are valued in both markets, consumers nowadays are equally unwilling to give up adherence to their quality standards.

The company’s engineers are therefore said to have been given the task of developing an oven that guarantees excellent baking quality, is precisely controllable, and can be switched over from one product to another very quickly. The design of operability and monitoring should be as simple and efficient as possible.

The outcome is an oven that not only looks markedly different to previous ovens from Barembach – including a contribution to better hygiene – but is also a kind of heating technology all-rounder.

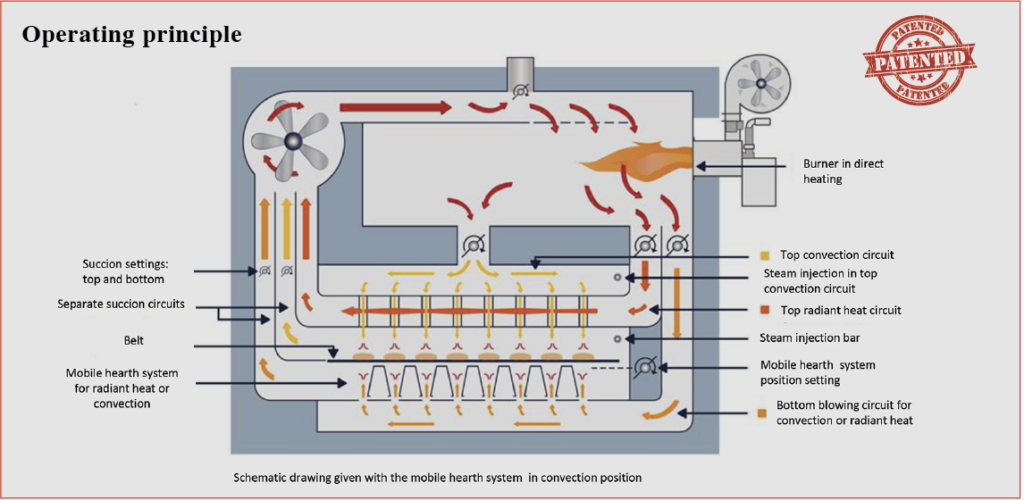

To understand this, one must take a look into the modularly constructed oven in which each module allows a variety of heat transfer options from above and below.

Six different heat transfer options for each heating zone

+ Convection from above and below

+ Convection from above, radiant heat from below

+ Radiant heat from above and below, hot air brings heat to the products

+ Radiant heat only from above and below

+ Radiation and convention from above, and only radiation from below

+ Radiation and convection from above, and only convection from below

A thick perforated plate heated by a stream of hot air is

suspended in the baking chamber above the baked goods, and can emit radiant heat downwards. On the other hand, blowing warm air through the holes in this plate creates an air movement that carries heat to the products being baked, i.e. via convection. The two principles can also be used in combination. In the case of the bottom heat, on the other hand, Thanks to the new patented „mobile hearth system one can decide between radiant and convection. This yields a total of six different heat transfer possibilities, and thus the right baking program for almost every product at any point in time.

The program runs at the press of a button, without the need to change slide valves or switches, which is beneficial to homogeneity when employing operators without much specialist training

The oven is divided up into heating zones with a maximum baking area of 25 m2 each. Each zone can consist of a different number of modules. The most compact oven of this kind is 17 m long, including the entry and exit zone, offers three different heating zones controllable independently of one another, and provides up to 32 m2 of baking area, depending on the oven width.

Heating is either direct using gas burners mounted above the baking chamber, or indirectly via heat exchangers and in that case with gas or oil, depending on the customer’s preference, or electrically.

Because not only can the type of heat transfer in each heating zone be regulated independently, but also the upper and lower heat can be heated by separate air flows, a fast response is possible and the oven can be operated with extremely product-specific baking profiles. The separate control over how and where the heat is brought to the product, to what extent and whether using radiation or air movement, gives the oven extremely fast mobility and reaction, especially as the burners are correspondingly dimensioned and deliver up to 80 kW/m2. According to Mecatherm, this avoids unproductive pauses between different products. Increasing the temperature by 100°C takes just 20 minutes, and a reduction of 100°C only 30 minutes.

For safety reasons there is a balustrade on top of the oven

Easy accessibility for cleaning and repairs; all the external panels can be dismantled without tools

Baking takes place optionally on a wire loop belt or a rod belt. Anyone who prefers to bake directly on the belt can on request have a belt preheating system to ensure that sufficient power is immediately available from below.

Each module comes with a steam inlet. For the air and steam extractors, the engineers placed value on the fact that no non-uniformity in the baking result occurs across the whole width of the oven.

Of course, even in this oven it is impossible to completely avoid a drop in temperature directly after loading the oven. But the combination of the use of a modulating burner that adapts precisely its operating rate and the rapid air change in the baking chamber ( 20 000 m3/H) permit a quasi immediate adaptation of the oven to the product load, and a very homogeneous baking even in case of partial loading;

An air management system ensures that equilibrium prevails between the air removed and the volume of inflowing air. This is done thanks to seven regulators in total, four to extract air and steam and three for the air inflow. The automatic regulation system of the stack valve avoids both a downdraught of cold air through the flue and the blowing out of hot air into the production rooms. It goes without saying that the oven’s controller has provision for programming product-specific baking curves. The program runs at the press of a button, without the need to change slide valves or switches, which is beneficial to homogeneity when employing operators without much specialist training. To monitor the baking process, not only do the usual windows provide a view of the products being baked in the oven, but also anyone who wants to can arrange for this process to be relayed by camera to the controller’s monitor screen.

The engineers also thought it worthwhile to think about accessibility for cleaning and repairs. All the external panels can be dismantled without tools, allowing quick easy access to the baking chamber, and so can the belt drives at the beginning and end.