Continuous dough production is designed with volume and efficiency in mind. Requirements stemming from the product characteristics, the manufacturing needs, the facility and equipment line-up will influence how continuous mixing and kneading should be set up.

Kneading with continoMIXX

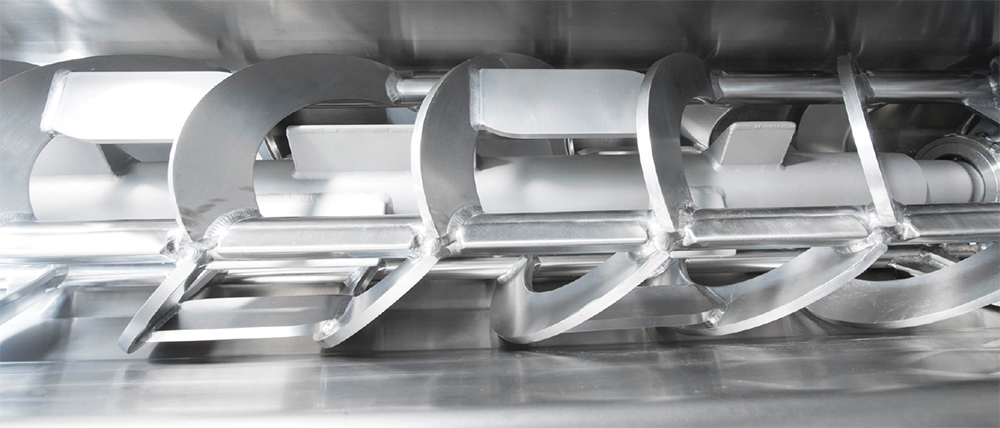

The continuous dough production system continoMIXX made by DIOSNA is recommended for any products using wheat. It features two independently adjustable tools and ensures optimal kneading, even when sizeable amounts of

residual doughs are added back into the system. “Due to the mechanical decoupling of the two tools (paddle drive and screw drive), the speeds can be set separately,” R&D Constructor Stefan Bensmann, DIOSNA, explains. Different types of dough can be kneaded using the same tools, which ensures fast recipe changes while reaching maximum flexibility in hourly performance and kneading intensity. Its design is also mindful of the space it occupies and it supports increased water absorption, which is beneficial in terms of volume, flavor and ingredient costs.

An interesting case of kneading optimization contributing to the overall efficiency is when residual doughs are added. In the case of uniform return dough (laminated dough, for example), it is added directly to the kneading chamber and the kneading process is adjusted accordingly. In the case of non-uniform return doughs, they are placed into a storage container and continuously added from there in smaller quantities (adjustable). “The gentle addition of return dough is absolutely necessary for large quantities of return dough to prevent the deterioration of the final dough quality,” explains Bensmann.

Another interesting feature is how the two independently adjustable tools work (for feeding and kneading). The specialist shares the details: “In the process patented by DIOSNA, it is possible for the first time to separate the energy translation from the conveying effect in the continuous kneading process. In the past, increasing the rotational frequency of the kneading tools increased both the feed rate and the kneading energy. Now, it is possible to control these parameters individually via two independently coaxial kneading tools.”

The so-called paddle tool, which is arranged centrally in the middle of the continoMIXX, is used exclusively for applying the necessary kneading energy without conveying the dough. “It can be conditionally controlled via a frequency-controlled drive in the range of 20-70Hz, which allows maximum flexibility in the targeted addition of kneading energy,” the specialist adds. The infeed rate, respectively the hourly output of the kneading plant, is realized via the externally arranged screw tool. Due to the specific arrangement of the crescent-shaped elements of the tool, the dough is conveyed and also permanently pressed into the effective kneading zone between the paddle and screw tool. This tool is also conditionally infinitely variable in the range of 20-70Hz and also offers the possibility of specifically controlling the filling level of the machine trough. If the hourly output of the metering systems remains constant and the speed of the screw tool is reduced, the filling level of the machine increases, for example. This measure would have a direct influence on the kneading energy applied to the dough without increasing the conveying effect.

To automate workflow, the continoMIXX records weight data and the parameters of the kneader at all times. In case of deviations from presets, the system will automatically issue warnings, error messages, or even shut down the entire plant if the tolerance values are exceeded.

The continoMIXX

Three different sizes are available:

+ Small: 1,500 – 3,000kg of dough per hour

+ Medium: 2,500 – 5,000kg of dough per hour

+ Large: 4,000 – 8,000kg of dough per hour