By Catalina Mihu

True to its motto, ‘Standing still is a step backward’, Kempf successfully completed its ambitious relocation project in little over a year. The new pin at Reutfeld 1, in Rohrbach, has officially been dropped on its brand new headquarters, reminiscent of a New York atmosphere. Not one to stand still, the bakeware specialist’s team brought German efficiency into the scene and is already at work in a new and improved home.

November 2022: Seven shovels breaking ground on a crisp morning marked the first visible sign of a long-thought-out expansion project. All things considered, including an unstable geo-political environment in Europe and beyond, supply chain disruptions and global inflation worries, Kempf made the timing work and built a 20,000 sqm headquarters containing the necessary expansion of its production facilities, with space dedicated to logistics and modern office spaces. One year and around EUR 30 million later, what started as an ambitious blueprint became a fully functional building for Kempf’s 140 employees currently working at the Rohrbach facility (and counting, with hirings underway, there should be 160 by the end of the year).

The factory gradually moved, line by line, over four months, before the end of 2023. Throughout this time, production never completely stopped. Desks, computers, favorite cups and all office logistics were transferred last, in the days between Christmas and the New Year. In early May 2024, baking+biscuit International was invited for a factory tour, this being one of the first visits Kempf received at the new address, prior to the official opening event, which will be staged after the summer. As the very last details were finalized, production was already 100% operational in May.

“Our goal is that we provide, in the end, PFAS-free coatings that have even better performance – better non-stick effect, easier to clean, and longer lifetime – compared to today’s fluoropolymer solutions.”

Guido Kempf, CEO, Kempf

The new space for work

The goal was to automate the production floor wherever possible and to bring onboard new technologies to increase efficiency and productivity. The move was required, on one condition: the business had to stay in Rohrbach, the small town where it started, some 50 km north of Munich. An opportunity came about for Kempf to buy the necessary land from local farmers, and the rest is history!

The new coating plant was the first facility to turn on its lights and start operating at the new address. It was the first glimpse of the development that was being prepared around it, and which f2m witnessed during our first visit, a year ago. The coating plant was designed with room for further capacity expansion right from the beginning.

Despite some unavoidable delays with construction logistics, the land around the hall designated for coatings quickly saw the rest of the building rise. Kempf is not only building, but also constantly seeking and researching new technologies it can use in its work. An important priority is sustainability, in this regard. This is why the new building’s roof is covered with over 6,000 solar panels, for instance. With the 2,100 kWp photovoltaic system, Kempf is sourcing electricity for its own production needs and for the building itself: “The floor of the entire production area has floor heating and cooling, for perfect working conditions,” Guido Kempf says, as he underlines, “Our workers are our biggest asset and as we continue to search for the best people, we want to offer the best environment.” This is why the walls of all production areas have perforated panels that help reduce the noise levels, too.

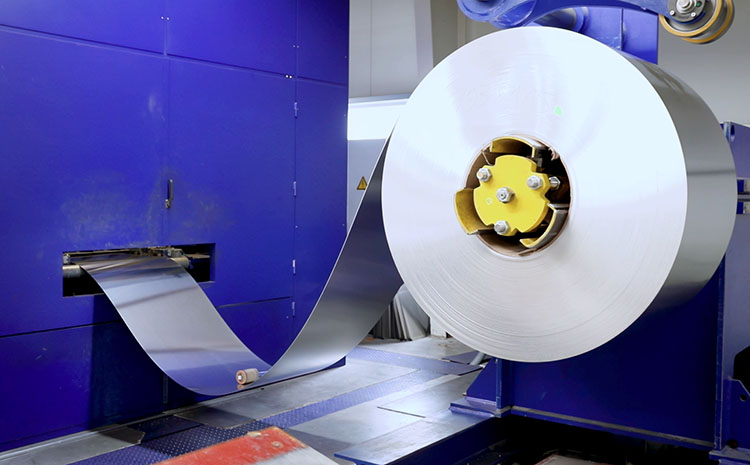

Today, the production capacity has been expanded by around 20%, compared to the old factory. However, the new production floor has, by design, free space around all existing lines, so it can still accommodate new equipment. For example, if a new perforation or a bending line is required in the future, it can be incorporated with no disruption to the processing flow. Materials, sourced directly from the plants and not via intermediaries, are delivered in coils, meaning that the trays can be produced without any scrap, as they are already the required size when they are sent to the automatic line for perforation. Because coils of different sizes are stored here, production can start within hours of placing an order. The punching unit can make up to 1,000 perforations in one motion. This translates into a perforated sheet for a standard 60 x 40 cm tray produced every 4 seconds. The parts that are punched out of the sheet are sent back to the aluminum plant, where they can be immediately melted and reused. Next, the sheet is flattened and sent to the automated bending units. Since the highest possible level of automation was a goal from the start, all standard products are made without any need for manual labor.

Production is planned over two shifts at Kempf, with a completely automated third shift being carried out with robots, overnight. The workers load the machine at 11 p.m., and it will run independently until 6 a.m. the next day, when the morning shift arrives. Standard trays for craft bakeries are usually produced on the night shift, and a stock of standard sizes is always maintained, for faster delivery times.

A section of the production area is dedicated to bakeware that needs a certain level of manual operations, such as custom requests, or small quantity orders. Baguette trays go through here too: “We make them semi-automatically, although they are made in large numbers, because every bakery has its own requirements about the specifications of the convolutions,” Kempf explains. This is why they are always made to order and there are no stocks. Once the correct convolutions are made, the trays are sent for coating and then returned, to be assembled on their frames. The frames can and usually are reused, up to four times.

Kempf’s newest investment was a robotic solution that automates cutting 6 m-long tubes. Welding also uses a robot. A separate section handles peelboard production, including larger sizes, which have recently been requested more. A dedicated production line makes deep-drawn tin sets, with numerous tooling options. A similar line is operating at KeyBAKE, the Dutch company Kempf acquired last year.

The storage area is used for standard-size tray stocks, as an in-between stop for trays going to and from coating. It also has a section that works like a ‘tray hotel’, where customers’ second set of trays can be stored long-term, on request (and for a small fee). Kempf’s main market is European, but it ships trays as far as Australia.

And the work in the new space: new developments

KEMPF

At Kempf, the R&D team continuously looks into product innovation, for all its product ranges: baking trays, most of which are perforated, trays with molds (e.g., for buns, croissants, and cakes), tin sets (for products such as toast bread and sandwich bread – also a big part of Kempf’s business), and trays for industrial systems – such as large baguette trays, as well as stainless steel racks. Another distinct category is customized solutions, developed to respect unique sets of requirements, such as baking branded products, and solutions to support tracking and tracing bakeware.

Among new developments, Kempf recently developed lightweight trays for Mecatherm production lines. “We have many possibilities to lower the weight; we can work together with our customer’s technical teams to identify the critical parts on the line and adjust them accordingly. In the end, every kilogram we can reduce from the tray’s weight will save a lot of energy and money per year, while it works on a 24/7 production schedule,” Kempf observes. The demand for this type of tray is growing.

Coatings: the time to test is now

The field of coatings is particularly dynamic, especially in light of the highly expected EU regulation regarding the use of PFAS, which currently holds the undisputed biggest market share. The regulation is bound to affect all industries in Europe, since PFAS are even used in clothes, for example, not just in baking, and will very likely be delayed from the tentative 2025 timeline, Kempf anticipates. But, it is a matter of ‘when’ (and ‘how’) and not a matter of ‘if’.

Silicone can already provide a possible PFAS-free alternative, and its adoption is on the rise. “For baguette lines or bake-off stations, it is still one of the best options because of its excellent baking results. Its open-pore structure has the ability to retain some of the water during the proofing process, and return it to the bread while baking. The result: uniform colorization and a crunchy crust, the perfect attributes for a baguette,” Kempf explains. By comparison, a baguette baked on Teflon will have less color and a drier crust.

In addition, the company has perfected a new solution, unique to Kemp, ahead of the ban on PFAS: plasma coating. “We’ve had very good results for all types of perforated trays, as well as bun trays,” Kempf says. Because of the application method currently used, the current limitations of this coating are deep molds – for toast, tin bread, or sandwich bread – and products high in sugar such as cakes. But, using plasma coating is very new and very much a work in progress, which is already showing very promising results. “The trays we are using on lines now are passing the 5,000 cycle mark, and on a smaller installation, this coating has already exceeded 10,000 runs and the coating is still as good as new. Plasma has the potential to be one of the best solutions for the future,” Kempf observes. “The problem with PFAS is not the Teflon we have in the frying pans at home or the Teflon we use here, in the plant, nor the Teflon used in the bakery; it stems from chemical plants using – and mishandling – the raw materials going into it, years ago. The current concern has to do with removing the risk of a new spillover in the future. I think this is not the best approach to this problem,” Kempf believes.

The new solutions join an older PFAS-free solution, which has been on the market for over a decade: ceramic coating. This comes with pros and cons – it is very abrasion-resistant, but using it regularly for baking makes its non-stick effect wear off very fast. This makes it a non-starter for baking.

Completely removing PFAS in coatings is virtually impossible in several industries, so drafting a functioning proposal is an ongoing conversation, the specialist notes. A possible scenario for a timeline could be for a consensus to be reached by 2026, followed by an extended transition period before eliminating PFAS, Kempf anticipates. This would allow ample time for new developments that will also ‘cover’ deep, molded pans, and additional solutions altogether. However, there are always companies that are early adopters when new regulations are established, so the request for PFAS-free solutions could become a real trend in the not-so-distant future.

Kempf currently recommends that bakers test the available alternatives, while their utilization is not compulsory and production rates will not be influenced. “Our goal is that we provide, in the end, PFAS-free coatings that have even better performance – better non-stick effect, easier to clean, and longer lifetime – compared to today’s fluoropolymer solutions,” Kempf anticipates. The plasma coating is a step in this direction. Acting as a surface treatment, it comes with the benefit that it cannot be damaged, i.e., peeled off while cleaning the tray with various cleaning agents.

KeyBAKE

Kempf added KeyBAKE Bakeware & Coatings to the group at the beginning of 2023, around the time when construction for the expansion project was starting in Germany. Perforated (bun) trays make up its main business, with a portfolio including bread pan straps, baking trays, baking forms, peelboards, coatings and racks. With a team of 35 people, it is also actively hiring, as it is increasing its production capacity to a two-shift operation. KeyBAKE is mirroring Kempf’s growth; coincidentally, it also relocated to a bigger headquarters spanning 3,000 sqm in the Netherlands, in a newly-renovated building, in November ’23. With the move, it invested in several machinery upgrades, including a 2,000-tonne press that can make trays up to 2,000 x 1,200 mm from a single piece of metal – in line with the trend of increasingly using bigger baking trays.

Inside and out

New HQ is more than the workplace for Kempf’s team,it’s a place where they now enjoy many new process automation upgrades; it is also a meaningfully thought-out socializing space, where everyone can feel they are appreciated and equally belong. People who work and celebrate together stay together: in a series of in-house events celebrating the new facility, employees can show family members around so they can see for themselves last year’s work in person, which came in addition to their day-to-day tasks.

Everything was planned in detail around the building itself too, with scenic areas including selected trees, and functional parking and loading/unloading spaces. If required, there is still adjacent land available for further expansion in the long term, when the time comes.