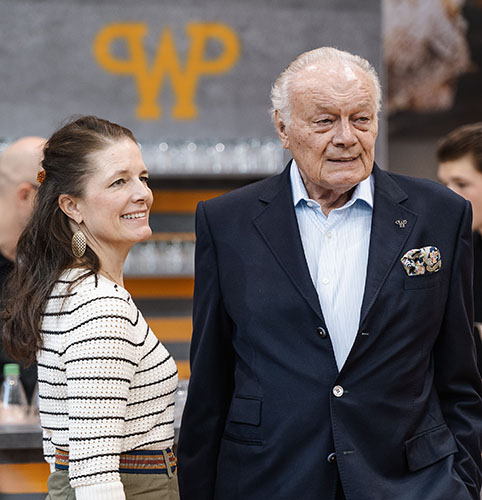

With its portfolio of companies, the WP BAKERYGROUP covers every step of the baking process with dedicated

and interconnected equipment. Jürgen Horstmann – owner, Horstmann Group, and Carola Landhäuser –

WP BAKERYGROUP CEO, share the insights of leading a diverse group of companies and looking beyond individual production steps when designing solutions, to a ‘think process’ big-picture that shapes innovation in baking.

Catalina Mihu: Earlier this year, we met at the AIBI Congress in Hamburg. What is your view on the baking industry’s latest approaches to current struggles throughout the supply chain?

Jürgen Horstmann: From a mechanical engineering perspective, energy efficiency, automation and artificial intelligence will shape the supply chain in the future. The goals of our new concepts are to reduce food waste, avoid disruptions, improve product freshness and ensure healthy production, in compliance with ecological standards. Today, WP uses automated modules in many different machines, in all the companies of our group.

However, the area of control systems has witnessed even more significant changes. Here, we have succeeded in developing software concepts that can run on different platforms, or operate different devices. As a result, we are less dependent on hardware and are no longer tied to specific suppliers. Today, for example, we can use an oven computer for a dough divider and vice versa. The only thing that counts is the software, and we have that under control.

Mihu: Mr. Horstmann, you established WP BAKERYGROUP, but the company’s roots go back almost 150 years, growing together with the baking industry. What key moments would you consider to be the cornerstones of today’s group?

Horstmann: I am pleased to say that all companies in the group have developed very dynamically. I believe that the acquisition of the fat baking technology was a decisive step for WP Kemper (ed., In 2012, WP took over a provider in the field of frying business). In this area in particular, we were able to bring some special developments to the market, such as the thermal oil-heated industrial donut system, which helped us to achieve enormous growth.

Another key event is the development of the WP Digital Portal with all the associated apps. This is the entry into a new era of plant technology. In the future, digital solutions – with and without AI applications – will contribute even more than before to differentiating products from the competition and offer our customers added value that helps them earn money – bringing improvements to the productivity of a system as well as in maintenance and service.

At WP-L, alongside our strongest product, the Tewimat bread dough divider, we have established deck ovens as a strong automation alternative for larger artisan bakeries. WP Haton has focused very successfully on more precise and, at the same time, more powerful bread dividers and has now expanded these systems to include new hygiene concepts in relation to the proofer. One of our latest developments at WP Haton is the Clean Proofer, which is particularly suitable for the production of gluten-free baked goods.

WP-Riehle has now moved into process automation, developing and marketing fully automated solutions, for example, for the production of frozen pretzel baked goods.

And, a few years ago, WPI B, our industrial division, built the first thermal oil-heated continuous oven with two decks, which can bake toast quickly and in outstanding quality, thanks to its special turbo technology. This has significantly increased the productivity of our industrial ovens and at the same time considerably reduced the space required.

What innovation means at WP

Mihu: What innovations brought new solutions for bakeries and, in turn, translated into a step up for the group in the industry?

Horstmann: In addition to purely technical innovations, all of our developments are aimed at making our customers more flexible and efficient, so that they can meet the

ever-increasing demands from retail and, above all, increasingly diverse requirements coming from their customers. Even large industrial companies have to be very flexible today because customer requirements change quickly. And our retail customers rely on differentiation through regional quality. We want to continue to build on this in the future and support them with special solutions where it makes economic sense.

One example is the KRONOS Kneader, a fully automated machine which, in conjunction with the MixControl feature, not only monitors the dough quality batch by batch, but can also be easily controlled by a non-specialist, even with fluctuating raw material qualities. In this way, the MixControl establishes the basis to further automate the entire process.

In addition, with the new development of the SOFT STAR CT, WP Kemper has laid the foundation for innovations in the fat-baking sector. It is a high-performance 60-cycle dough divider and rounder with an unprecedented hygienic design. Milestones include the production of mini Berliners (8 grams) and mini donuts (15 grams).

In the WP Digital Portal, WP bundles all digital solutions to make service faster and more economical. New apps, such as augmented reality service support (FacelT} or a condition monitoring system (ControllT), which gives plant experts access to machine data via a digital twin, are just the first examples of innovative new solutions.

With the development of new web-based user interfaces (HMI), which are graphic-based and interactive, in conjunction with the WP Digital Portal, new solutions for improving operations and further automating systems will be possible in the future. The use of solutions incorporating AI and some completely new control concepts (for which we have already applied for a patent) will soon complete WP’s range of services and take the performance of systems to a whole new level.

Jürgen Horstmann, owner, Horstmann Group

The power of a cohesive group

Mihu: What is your view on the various ways of achieving company growth, including expansion, acquisitions, partnerships?

Horstmann: With the development of WP Kemper, we could and can grow quickly and sustainably through suitable acquisitions with truly complementary product portfolios. In my opinion, this is the only way forward. That is why we are constantly monitoring the market, and we are currently examining each of the many offers very carefully. I don’t believe in simply merging companies into a group that is difficult to manage. I think it is ultimately more successful to grow more slowly, to take more time to integrate new companies and to integrate the new types of technology systematically from the outset, so that all companies in the group can learn from them and, of course, benefit financially.

Mihu: Please describe how the collaboration within the group is managed. What leadership style do you find works best, as a system provider with several competence centers in its structure?

Horstmann: Our management style demands and promotes commitment and creativity in order to enable rapid adaptation to new challenges and complex dynamics. This means that we cultivate a situational management style combined with agile elements in order to make quick and good decisions in rapidly changing markets.

Mihu: What are some of your favorite customer projects and key moments in the Group’s work, and what makes them memorable? Please share some examples.

Horstmann: One example would be the first OBER system, which we installed at a bakery in the Rhineland in Germany, many years ago. Since then, the OBER oven-loading robot has now covered a distance equivalent to circling the Earth several times. It is a solid machine, which is why, over the past 25 years, we have only had to replace the cables and the starter, which were of course outdated.

Also, the WPIB 2 thermal oil baking oven, which today bakes almost 10,000 kg of bread per hour in Sweden, was one such project, as was Kemper’s first open kettle baking system in Spain, which bakes 40,000 donuts per hour.

Special projects in the artisan sector also come to mind, such as the continuous tunnel vacuum cooling system for panettone in Switzerland.

Mihu: The HORSTMANNGROUP sees itself as a medium-sized group of companies with diverse specializations and an international reach, as described in its official presentation. Is this still how you envision the group’s future?

Horstmann: Good WP products have been in demand on the global market for more than 100 years. In addition to Europe, our most important markets are North and South America, but we are also focusing on the future growth markets of Africa and Asia.

Mihu: What are the unique values on which the company is run, which stem from it being family-owned?

Horstmann: In a family business, agility should be demonstrated through short decision-making paths, but the virtue of patience should also be taken to heart. Encourage and challenge managers – is what I promote; create a positive working environment that leads to responsible action.

Looking ahead

Mihu: In the baking industry, the Group has grown from starting with a single dough mixer to providing integrated bakery solutions under the motto ‘think process’. What does the future hold for the family-owned company in the development of process improvements for bakeries?

Horstmann: The shortage of skilled workers will remain a challenging problem for bakeries in most countries around the world. Concerns about the next pandemic, which is of particular importance in food production, remain omnipresent. In this context, I expect the automation of workflows and processes to continue, so bakeries can become more self-sufficient.

In the coming years, we will see many more collaborative robots in factories, we will see ovens and machines that will be able to make decisions previously left to the operators. The use of AI will further increase productivity and make production much more flexible. That is why we are investing in the development of new systems and technologies in this area in particular. I believe that, in the future, we will need much more software development, database technologies and augmented reality applications, in addition to the established areas such as production, design and electrical design. In order to adequately support our customers in times of a shortage of skilled workers, we need to become much more resourceful with digital solutions. We can only exploit the potential of these new technologies if we provide our customers with machine and process expertise at all times. 3D glasses, for example, will soon be an integral part of the service. We want to be prepared for this, work on it and grow with it.

Mihu: And how do these values shape its growth? What is your message for bakeries, long-standing and new partners, regarding the group’s next-generation leadership?

Horstmann: The values practiced by our management staff will secure the future of the WP Group. My daughter and her management team will work hard and innovatively to maintain the long-standing trust and loyalty of our customers for decades to come.

“Think process”

The central element of our corporate philosophy is a networked way of thinking that stretches beyond the individual stages of production. We call it ‘process management’, the targeted management of the individual stages of production and the machines used within them – as fast and with as little loss of material as possible to achieve the desired result, even for small amounts – and the unlimited reproducibility of results achieved. And all this is combined with extremely high yield.

WP BAKERYGROUP

The next generation

Mihu: Looking at leadership succession into the second generation, how would you describe your own path leading up to it, and your approach to spearheading the Group into your new role, Mrs. Landhäuser?

Carola Landhäuser: I got my first management position in our group of companies 20 years ago. Since then, more and more companies have been gradually added; then, the WP BAKERYGROUP leadership, four years ago. Two basic things are crucial for me: to lead authentically and gain as much specialist knowledge as possible. This is the most goal-oriented way to get from A to B with employees.

Mihu: What challenges did you confront that have also influenced this path?

Landhäuser: It was and is challenging to constantly analyze and keep an eye on the WP Group and its individual organizations (GmbHs) in such a way that I can quickly assess strategic issues in any area, what the risks are and where I need to intervene and how.

This is not a trivial task, given the broad and multifaceted field that I have to cover, as decisions have to be made quickly and correctly. A second attempt at wrong decisions, which sometimes undoubtedly occur, is usually more timeconsuming and gives room to doubters and complainers.

Mihu: What unique value will the group gain from heading into a new chapter under the leadership of a woman?

Landhäuser: There are certainly stereotypical differences in the leadership of men and women. I find the mixture beneficial. I am very calm and level-headed, which helps me manage any situation, including dealing with the most headstrong personality types. You could say this is feminine or maternal. However, I also know male managers who act like this. And, there will always be employees for whom a louder and more direct approach is more appropriate. It helps me a lot that I have seven children, five sons and two daughters – nothing can shock me.

Carola Landhäuser – CEO, WP BAKERYGROUP

Mihu: What is your view on women’s representation and career opportunities in the industry? And how does the Group support it?

Landhäuser: Most industries are still very male-dominated. I don’t believe in quotas for women. Tasks have to be accomplished and goals achieved. Whether you are a woman or a man, you have to take action and perform well. Due to the lower representation of women, the vast majority of men are simply not used to coordinating with women. But this can be trained. Unfortunately, I am convinced that this often leads to men opting for what they are used to, so yes – in my opinion, the chances are not equal for women.

Mihu: Expanding on this topic, since (the lack of) people is one of the most prevalent issues today, how can the industry tackle labor shortages successfully? What has worked for the group?

Landhäuser: As long as we can describe as precisely as possible the areas in which we are looking for support and what exactly we expect from the people who come to us, we will always be able to find new employees. We are an international company and we see our future growth largely in foreign markets. Therefore, we have been trying for some time to become more international in our recruitment. This is a change for our company and an important one, which we will continue to pursue consistently.

Fortunately, we now have the advantage that women are also interested in engineering and other technical disciplines, so the overall recruitment base has expanded. We have already made some adjustments to our working time models during the pandemic, for example, by enabling and maintaining home offices in many office departments. This is, obviously, not possible in the production areas, but here, too, we are trying to optimize assembly processes by providing information on large screens and, as far as possible, communicating to each of our employees why we are doing things in a certain way and what the end-result should be.

A changing landscape

Mihu: Looking back at the baking industry over the past decades, how would you compare its main requirements, then and now?

Horstmann: While, years ago, it was all about producing as much as possible as cheaply as possible, today the focus is clearly on quality, product safety and variety. Yesterday’s ‘plentiful’ has become today’s ‘diverse’, yesterday’s ‘affordable’ has become today’s ‘fast’, and yesterday’s ‘packaged bread with preservatives’ has become today’s ‘safe, high-quality food for everyday use’, in environmentally-friendly packaging and in small quantities.

Mihu: What new approaches to today’s production problems could help bakeries advance at this turning point in the world economy, politics and business – all intertwined?

Horstmann: Bakeries produce staple foods. The demand is high in some countries around the world, but the infrastructure is still lacking. Government-funded projects can help to improve supply here. We are now able to plan and develop entire bakery operations, from the floor of the building to the machinery and equipment, the laboratory and the test bakery, to the air conditioning on the roof (a comprehensive example of this kind is the Xazri bakery in Baku, Azerbaijan, which we supplied a few years ago). Let’s look ahead, for example, to the situation in Ukraine when this unfortunate war is finally over. Everything will have to start from scratch again. Holistic concepts can help to rebuild supplies more quickly.

Bakeries are energy-intensive businesses that require considerable resources in the form of drinking water, cleaning water, electricity and fuel. At the same time, they are often easy to identify when coming to their immediate vicinity. The smell of fresh bread wafts far and wide. In the future, it will not only be important to make the production process more resource-efficient, but also to make the waste heat generated during the baking process available in local energy networks for heating or other processes and to neutralize odor emissions using suitable systems.

Bakeries continue to pose a logistical challenge in terms of the 24-hour transportation of goods, both for incoming and outgoing products. We are seeing the beginning of a shift towards hydrogen trucks or battery-powered smaller delivery vehicles. While we are already seeing numerous approaches to optimizing internal logistics with autonomous AGVs in bakeries, external logistics are still largely handled traditionally with trucks. I think that we will see many changes here in the coming years.

Jürgen Horstmann, owner, Horstmann Group

Mihu: On the topic of today’s turning point, what is your view on practical approaches to sustainability – for you and for the bakeries?

Horstmann: As I mentioned, resource-saving processes, energy recovery, but also the export of waste heat, for example to urban heating systems, can provide ways to reduce overall energy requirements. A kilogram of bread will always consume around 200 Wh of energy before it is baked. We want to stick to this, from a food quality perspective. But, the way in which the energy is used to bake the bread can still be optimized. Then, there is the distribution of the goods, as I described. Even more important, however, is the last step in this chain, the collection or purchase of baked goods. After all, if the consumer drives to the bakery in the morning in their combustion-engine car to buy a bag of bread rolls and then drives home again, all efforts to reduce the ecological footprint of these 10 bread rolls are nullified.

Changes must also be made in the last mile if we are serious about protecting the environment.

The SOFT STAR CT divider and molder

The SOFT STAR CT dough dividing and molding machine produces dough pieces with very high quality and weight accuracy. It is designed to optimize dough forming for small baked goods, including formulations with particularly high dough absorption rates and bowl rest times. With a weight accuracy of ~1 g, it ensures a gentle dividing process and precise rounding.

It is particularly easy to clean since the drive and dough processing areas are kept separate and all parts that come into contact with the dough are easy to reach. Flour collection drawers also contribute to making cleaning easier.

Innovation that evolves with the times

Mihu: How does a technology/solution specialist remain innovative over time?

Horstmann: I am not worried that we will remain at the forefront of technology in Germany. We have a solid training program, making skilled workers and good engineers. As long as our management focuses existing capacities on the continuous improvement of our machines and systems, we will be successful. But, developments that can change the industry will only come about, in my opinion, if we give the teams the freedom to think outside the box, try new things and make mistakes, to explore, so to speak. Of course, commercial success is needed to be able to finance such developments. That is what we stand for as an entrepreneurial family, it is part of our DNA.

Mihu: What emerging ideas that could bring significant process improvements in bakeries do you find the most promising?

Horstmann: Robotics in handling, AGVs in internal transport, machine learning in our control systems for ovens and machines and, last but not least, the sensory recording of all process steps and the integration of this information into a digital model, the digital twin of the roller, so to speak.

Mihu: What process steps are in your focus in particular, for next-generation advances in the production of baked goods?

Horstmann: Of course, we are particularly concerned with the steps in the process chain for which we manufacture equipment ourselves. These are dough production, dough processing, proofing, bagging and cooling. We are working on the precise control of dough development in the kneading process and expect further, decisive optimizations here. In addition to hygiene measures, we are working on control mechanisms to avoid rejects during dough processing.

We are working on the precise control and distribution of adiabatic humidification in the proofer. At the same time, we have now installed the first energy-network proofers, which are heated with the waste heat from their ovens. We are working on shortening the baking time by modulating the radiation wavelength emitted in the oven. We are working on cooling processes in a vacuum, both in batch and continuous processes, and expect to be able to cool baked goods gently while saving energy.

Many fields with many tasks, but also with great potential.

Mihu: We are looking forward to learning about the new developments as they are launched. Thank you for an insightful conversation.