By Catalina Mihu

The first Lesaffre Baking Center™ was opened 50 years ago, as a place where its specialists could not only put themselves in their customers’ shoes to understand their experiences – from baker to baker, but also roll up their sleeves and bake together to find product and process improvements. Since then, it has become a network of 52 Baking Center™ facilities (and counting), busy baking with manufacturers all over the world, from craft and industrial bakers to baking equipment makers and millers.

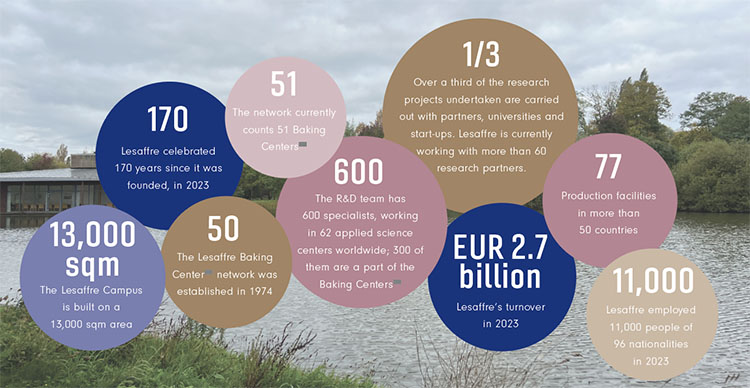

This year, Lesaffre celebrates the 50th anniversary of its Baking Center™ network, which today spans the entire world, from Austria and Hungary to Brazil, the USA and Chile, from Egypt and Morocco to China. Each specializes in serving its region of residence, with its cuisine and baking traditions, techniques, flavors and perspectives on innovation. A multicultural team of more than 300 specialists with different fields of expertise make up Lesaffre’s dedicated teams at the Baking Center™ network. Information and know-how are exchanged as a vast database is continuously built.

The concept

Lesaffre is developing its global network of Baking Center™ facilities to meet the needs of bakers everywhere, through joint projects. They are places where innovations are created, with practical research of each project stage, from concept to product, that can be seen, touched, smelled and tasted. They can tackle diverse issues, such as new product development, recipe improvements and technique finetuning. Bakers come here to test anything from technology innovations to processes and the implementation of new concepts into production. Lesaffre’s experts help develop solutions to specific needs and are researching market expectations and changing priorities.

At the same time, Lesaffre uses the centers to further its own expertise and develop and tailor solutions, with information it gathers from the vastly diverse food cultures and unique products from the world’s markets.

To celebrate half a century’s work on its Baking Center™, Lesaffre organized a suite of events throughout 2024, at each facility in the network. Internal competitions, baking demonstrations, inspiration sessions, workshops and training programs, seminars and international exchanges are among the events that created an engaging celebratory year.

Several projects and communication campaigns shed light on the specialists’ work, including the publication of a new book, published in French: ‘Les Pains du Monde’ and English: ‘Breads of the World’. The book reflects a jouney in breadmaking, undertaken by Lesaffre bakers who have choosen 40 original bread recipes, selected for their originality and authenticity. It was a difficult selection to compile, given the breadth of available options.

The bakery experience

It was in France, Lesaffre’s home country, where the concept was formed, and the first and biggest Baking Center™ was developed. Led by Gaëtan Jegoux, Baking Center™ Director, the team here works together with visiting bakers for specific answers to any number of product, process, or concept questions. Six bakery laboratories have been set up as a part of the Baking Center™ in Marcq-en-Baroeul, each with a different specialization and corresponding equipment: bread, pastry, pizza, sourdough (the interactions between the bacteria with the strain of yeast are analyzed here), and a fermentation lab. The pizza testing bakery, for example, lines up all the equipment commonly set up by a pizza maker. Investigating every step, ingredient, timing, and parameter ensures a perfect pizza is systematically done. It is only complete when even the cardboard box is analyzed, along with a standard delivery bag, to ensure it arrives at the consumer’s door exactly as intended: in the best possible condition.

Everyone working at the headquarters in Lille has, at one point, paid a working visit and enjoyed a hands-on learning experience here, says Jegoux – meaning, a team of approximately 700 people. Given its rich, festive agenda, 2024 was an unmissable opportunity to visit the Baking Center and Lesaffre’s brand-new Campus in Marcq-en-Baroeul. For a full day of ‘VIP internship’, thanks to exceptional French hospitality, a working visit was an illuminating first-person contact with innovation at the source. For one day, the Center’s celebration event agenda also included baking with BBI magazine. From mixing to resting, sheeting and cutting, forming and scoring, rolling and folding, baking and tasting (and a bit of magic!) – the program included the preparation of four French staples: traditional baguette, brioche, croissant and pain au chocolat. The hands-on baking experience was complete with detailed formulations and information about every process step, as well as expert advice along the way, including ways to improve the products, courtesy of Gaëtan Jegoux and Alban Depierre, Baking Technical Advisor. The difference between writing about the craftsmanship required to trace the perfect scoring on a baguette and actually doing it? Invaluable.

Bakers can work on many different projects here, ranging from customized training in the form of such practical sessions (and Lesaffre can also organize training programs at their facility), to seminars on anything from yeast and fermentation, to baking and freezing, or optimizing product shelf-life. Product sensory testing for potential reformulations or new developments is also possible on site, for example.

The Lesaffre Campus: ‘Le Baking’

Vibrant Lille, the third-largest city in France, was the European Capital of Culture in 2004, when it was also recognized as ‘Ville d’art et d’histoire’ – ‘City of art and history’. Lille stands out for its music scene and hospitality, its Flemish-inspired architecture, and its renowned university center. It is also home to Lesaffre’s state-of-the-art Biotech Campus, opened in 2022. Brice-Audren Riché, CEO, Lesaffre, shared the Group’s intention to give innovation R&D a new home with the new Campus: “The inauguration of our Lesaffre Campus is a historic milestone in the Group’s development. This living space arose from a desire to express what we are: an innovative, eco-friendly and open-minded company that has strong local connections. It embodies the spirit of our Group, which has been working for 170 years to explore and develop the infinite potential of fermentation and microorganisms. Inaugurating our Lesaffre Campus illustrates our aim to accelerate the research and development of innovative solutions to take up the challenge of improving food, nutrition and health for tomorrow.”

Projects at the Lesaffre Baking Center™ network

+ Product and process development

+ Technical support

+ Baking trials

+ Sensory analysis and product testing

+ Training, seminars (on location, at the bakeries, online)

Baking, anytime and anywhere

The Group’s products are available in over 185 countries. The company leverages fermentation innovation for its solutions, which are produced in 77 facilities and include:

+ Baking ingredients (mixes, sourdoughs, functional ingredients, yeasts)

+ Fermentation products

+ Nutritional solutions

+ Solutions for flavor and taste

The objective of the Campus was to gather everyone in one place: “When the group was growing, our offices were hundreds of meters from here. We had a factory nearby, and some offices here, but each team was, to a certain extent, separated into different groups. In line with our mission to work together to better nourish and protect the planet, it now starts by working together, literally. This was the concept behind regrouping everybody on the Campus, so we would all share the same place, value and project,” said Thomas Lesaffre, Baking Marketing Director of Lesaffre Group during our tour of the new complex.

In the building at the entrance to the Campus, an auditorium with an immersive lake view was set up, in line with a general preference for glass walls. Here, events such as seminars are organized. It can welcome as many as 250 people. In this building, the company’s motto is displayed: ‘Entreprendre ensemble pour mieux nourrir et protéger la planète’ (‘Working together to better feed and protect the planet’). This wall has already become an instantly recognizable landmark at the Lesaffre Campus, as it is the background for many of its developments, with their corresponding photo opportunities.

The buildings in the Marcq-en-Baroeul complex, in suburban Lille, span 23,000 sqm, 60% of which is space devoted to R&D, which is an essential department at Lesaffre, with plans to increase its dedicated budget by 10-15% annually in the upcoming years.

Envisioned as a ‘co-construction’ space, the Campus comprises 750 workstations and 600 meeting/project areas, as well as a learning center: the Léon Lesaffre pavilion. The facilities were developed as an entirely ‘green’ concept, inside and out: sustainable working spaces equipped with latest-generation technology, complete with buildings for dining and exercising, all pleasantly spread in a veritable park. The well-thought-out architecture and layout were designed around transparency and ease of access, in a natural environment. All to support teamwork: to easily share good practices, build resource databases, create partnerships and share know-how. Convenient, yet unobtrusive parking spaces between the facilities, so the eye can immediately enjoy nature, from any alley, from any of the buildings: trees, plants, a farm, and even a lake with resident swans and other migrating birds that have chosen the Campus as their yearly home. The traditional farm was recently revamped to allow visitor hosting and events.

The facilities set up here allow Lesaffre to step up its research in food, animal feed, health, environmental protection, energy production and industrial biotechnologies. “Our R&D approach is based on these emerging state-of-the-art technologies supported by historical knowledge and especially by the expertise of engaged and passionate teams,” said Christine M’Rini Puel, Chief R&D Officer for Lesaffre.

Not far from the Campus, more ‘green’ upgrades are underway in Marcq-en-Barœul, reflecting Lesaffre’s sustainability priorities: two high-power heat pumps will be commissioned in 2025, for a heat recovery unit that will enable the heat generated by the fermentation process to be reused. It is installed in the Group’s largest yeast plant, Société Industrielle Lesaffre.

The sensory lab

The Campus also houses facilities dedicated to sensory analysis, where specialists and volunteers carry out tests designed by Lesaffre’s experts. Camille Dupuy, Sensory Baking Manager, is setting up product tastings in a sensory-

controlled space, useful for various projects, including product differentiation, reformulation, or new product development.

An important project here, developed with the Baking Center™, is perfecting a common ‘language’ describing tastes, flavors and textures. The books not only catalog a complete sensory glossary around specific products, but also provide information about them, including recipes from around the world. Serving as a communication tool, several books that coin useful and practical terminology have been developed and make up an important, growing collection. <“Le Pain” in Words >, for instance, proposes an entire glossary of sensory terms that describe crusty bread. For clarity, this includes breads made with no added fat, or sugar, which have a brown crust, and are baked on a hearth, tray, hot plate, or in dry and steam heat.

From yeast research to robotics-run biofoundry

Advancements in work with bacteria here include the biofoundry, the biggest of its kind in Europe: a set of 60 specialized robots that simultaneously perform microorganism screening and analysis at high speed, to establish their profile and functional potential. From the test results, the best matches are selected for their properties and potential benefits. In this way, thousands of strains are tested every day, followed by advanced data processing. Thanks to the new robotics setup, it can perform 10,000 tests per day – a significant step up from the previous capacity of 10,000 tests carried out per month.

To put this work into perspective, for 100,000 screened strains to identify potential candidates, it can just be a selection of only 15, for example. These are tested for production viability, to check how well they scale up, in stages. If the process is replicated successfully to 1-2 m3 fermenters, a pilot yeast/bacteria variety has been obtained.

The R&D work at the biofoundry is also used by other departments on Campus, for in-depth, focused analyses related to biological processes. Studies around nutrition even include work with a model of a human digestive tract.

Lesaffre milestones

Louis Lesaffre and Louis Bonduelle launched a grain alcohol and Dutch gin plant in Marquette-lez-Lille in 1853. The first mill was acquired 10 years later, in Marcq-en-Baroeul, which became a distillery. The Société Industrielle Lesaffre was born. In 1923, the company shifts focus to yeast and malt, which goes on to drive its growth.

The development of the Saf-instant® Dry Yeast in 1973, a dry yeast that didn’t need to be rehydrated before being added to the mixer, quite literally put Lesaffre on the world map: “It was quite a revolution in the yeast market. This long shelf-life product allowed us to export from France for the first time, to Africa and the Middle East. This invention was paramount to our international development,” emphasizes Thomas Lesaffre.

One year later, the first Baking Center™ opened with the motto, ‘From baker to baker’. “This is why then in 1974, we decided to invest in a Baking Center,” he adds. “We hired a baker, just to put our feet into customers’ shoes, and to begin to better understand their needs. And over a period of 50 years, we have been building approximately one Baking Center per year, around the world, which brings us to today, when we count 52, with different specializations: the Chinese teams are experts in steamed bread, the teams in Turkey master flatbreads, and in France, we have people who are experts in baguettes, while in North America, our experts excel in toast bread. Today, we animate this network from here, to leverage all these

experts to develop new solutions.” Every year, more than 18,000 projects and events with customers are conducted in the Baking Center™ network.

The Group acquires Red Star Yeast & Products in the US in 2001, while also entering the Chinese market, with the purchase of the Ming Guang Yeast facility. In 2024, several new acquisitions expand Lesaffre’s capabilities in its four core areas: baking, health care, biotechnology and food taste expertise (baking being the main core business). This year, dsm-firmenich’s yeast extract business joined Lesaffre. The majority stake in Biorigin was also acquired this year.