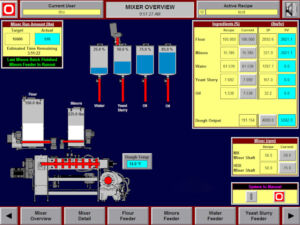

Automated continuous mixing delivers real-time process assessment and consistency round the clock. Continuous mixers allow for all parameters to be constantly monitored and saved digitally, including ingredient stream rates, dough temperature, mixing energy input, throughput, mixer shaft speed, coolant temperatures, starts and stops, ingredient refill status, ingredient totalizers, dough totalizers, and many others.

Systems ready for the unexpected: Exact Mixing

Exact Mixing’s continuous mixing systems, for example, are fully automated, meaning that the operators need only respond to alarms in case readings show parameters deviate from preset values, which doesn’t happen very often. The collected data is saved and used to generate graphs to compare actual values against set points. Information quantifying the dough production is also available, with details about its current progress, the amount completed per shift, or sorted by any other criteria that are useful to production.

“In the control system, all parameters are constantly monitored, and statistical analyses of parameters are available. The available information is only limited by the imagination of the person seeking the data,” Jim Warren, Vice President, Exact Mixing, explains.

“Technology is constantly improving”

To ensure accurate ingredient metering into the mixer, Exact Mixing is ensured using technology including loss-in-weight dry metering technology and mass flow liquid metering technology. The measurements recorded are continuously compared with the setpoint data to adjust the process if necessary, or issue warnings if automated corrections are not possible, to protect consistent dough quality.

The company has recently developed systems that accurately meter ingredients such as solid shortenings, nut-butters, diced cheese, and dried fruit. Its continuous mixing technology also receives regular improvements. “For example, we now offer five distinct continuous mixing models for different applications and customer requirements. The HDX Mixer is just one example of technology expansion,” he details. More recent technology breakthroughs include the high-speed developer and Hydrobond Technology instant hydration unit, which can be fitted onto existing systems.

In addition to these advancements, automation features can be included, with many options available to choose from, such as the automated control of the ingredient and water temperature, automated dough re-work, automated control of the dough hopper level downstream – to name a few.

Read the full article in Baking+Biscuit International, issue 2.

Related articles: