VMI shared in an interview the latest solutions that will be presented at its IBIE booth this year, in Las Vegas, from the latest planetary mixer, Phebus, to the Virtual Reality area.

What solutions are you highlighting at IBIE?

VMI will be exhibiting its range of mixing equipment on stand #1001: vertical, planetary and continuous mixers. The expertise shared by Shick Esteve and VMI will be showcased with a global solution for continuous ingredient handling and mixing processes.

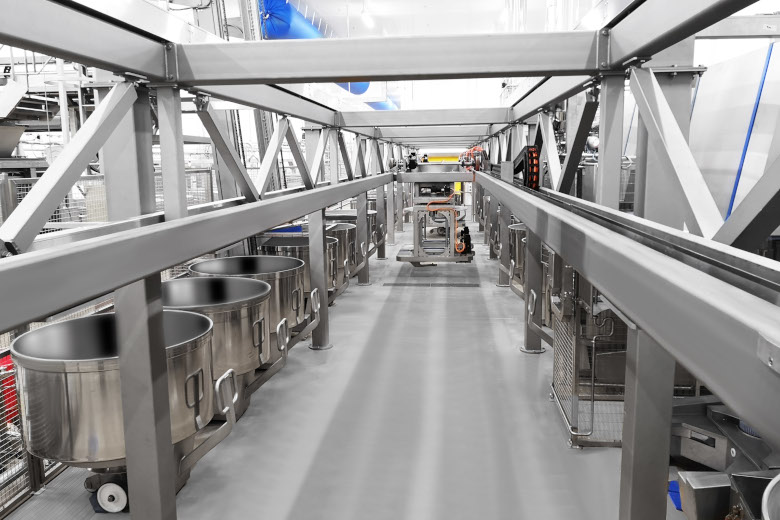

We are also excited to introduce our Virtual Reality Area. This new technology will transport the user into an immersive experience to discover mixing systems that integrate several mixers and automate the progression of batches from one station to another. Attendees will be able to walk through a full-size batch mixing system to understand the process and capture how it will perform in reality.

As our product range includes specific configurations to meet manufacturers’ needs, VR allows visitors to experience large automated systems free from physical constraints.

What new innovations or updates do they incorporate?

We will showcase our latest planetary mixer for the bakery and pastry industry: The Phebus mixer. It has a bowl capacity of 200 liters and features an ergonomic and easy handling design, ensuring the safety and comfort of your staff. Hygienic stainless-steel design guarantees food safety. This mixer excels in the most complex preparations, including creams, sticky doughs, batters and specialty breads. The intuitive touchscreen interface makes it possible to program up to 100 recipes for daily consistent and smooth production.

We also want to bring forward our ability to design custom solutions to each industrial challenge. We make available various mixing technologies adapted to ingredients, process, and location constraints. At IBIE, we want to highlight the many options offered by our batch mixing systems, which can integrate vertical mixers with removable bowls, fork mixers, or planetary mixers. These mixers can be combined with additional systems such as elevators, hoppers, shuttle for bowls transport, and conveyor belts to create automated production lines.

Custom-designed mixing systems ensure versatility of recipes and processes, from simple to elaborate mixing processes for bakery, pastry, or snack food productions: fermenting, autolysis, degassing, differed ingredient proportioning, incorporation of sourdough, scrap dough, inclusions, etc. operation traceability is possible thanks to the intuitive HMI (history of information elements, data import and export). Our mixing systems also offer optimized cleanability: automatic cleaning of batches, reduced water consumption and enhanced food safety.

What markets/product segments are in your focus?

We design equipment for the baked goods industries, covering a wide range of end products: white bread, sandwich bread, traditional bread, Viennese pastry, biscuits, muffins, cake – for each product type, we offer a mixing solution suited to the rheology of the dough. Our main focus is to make mixing technologies our customers’ best ally in meeting their challenges, whether they seek to increase efficiency, diversify their production, integrate environmentally friendly or sustainable practices, or improve traceability, cleanability and quality management.

Read more exhibitor previews in Baking+Biscuit International, issue 4 – 2022.

Photos: VMI (pictured in the main image: automated mixing systems)