Anton Paar has launched a new analyzer, the Brabender ExtensoGraph, that can better determine the rheological properties of dough, surpassing its predecessor in terms of user-friendliness, precision and versatility.

By: Matthias Mayser, Department Manager Product Competence Food, Anton Paar TorqueTec GmbH

Ensuring consistent dough quality remains a complex challenge for the mills and bakeries.

Variations in flour properties and processing conditions can significantly impact the final product. Factors such as gluten elasticity, gas retention, and fermentation stability must be closely monitored to ensure consistent quality in various applications. Additives with different fermentation times add another layer of complexity, making analytical tools a must-have.

Since the 1940s, the Brabender Extensograph has been used to successfully replicate and quantify real dough processing conditions. The device measures the dough’s resistance and extensibility, so that its critical properties can be understood in a practical manner. The Brabender Extensograph performs evaluations of the biochemical changes in the dough over extended fermentation times (45, 90, and 135 minutes), closely matching industrial baking cycles. These measurements of the dough properties lead to a better understanding of the product’s characteristics, including their volume and their crumb.

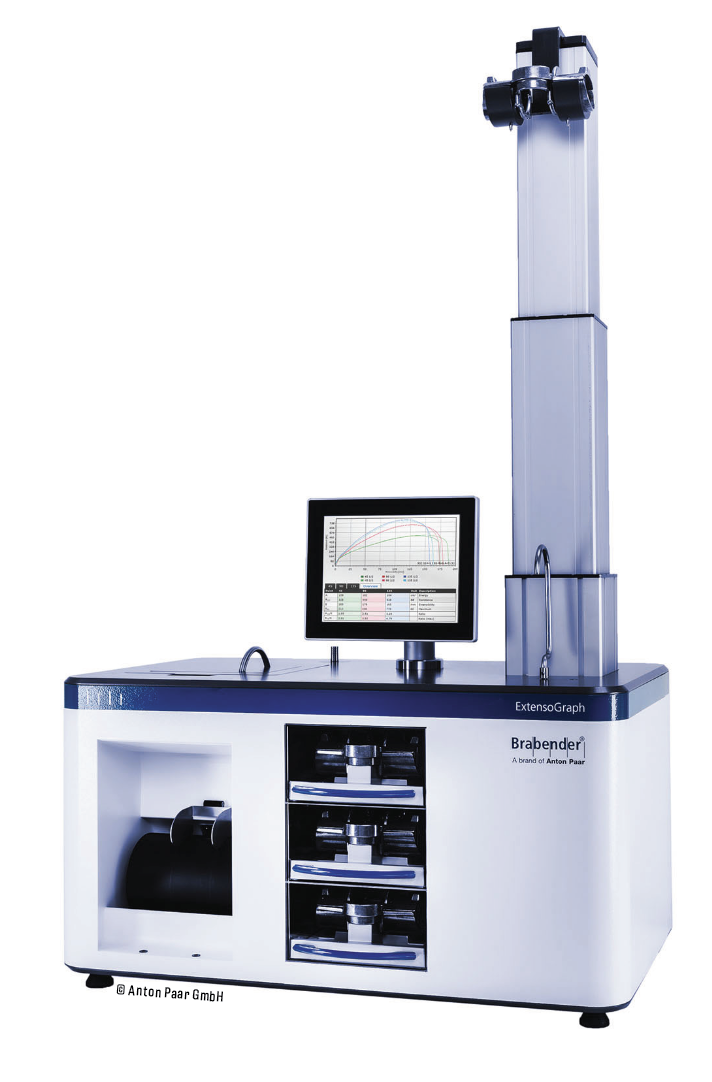

Fig 1: The new Brabender ExtensoGraph, featuring an extensible column, does not require any external peripheral equipment to operate

This is especially beneficial in assessing the long-term effects of flour additives such as ascorbic acid or enzymes. The analysis device is suitable for the quality control of baking aids and other additives used in dough production as well as for research and development purposes, where the focus is on optimizing recipes.

The Brabender Extensograph complies with international standards flour and dough testing such as ICC 114/1 and ISO 5530-2 for flour and dough testing. This conformity ensures the results can be compared with industrial benchmarks. It also simplifies communication along the value chain, and supports consistent analyses being carried out at any stage, from incoming goods inspection and production control, to research and development.

Anton Paar now introduces the newest generation of its analyzer for dough processing and baking behavior, 85 years after launching the first model. The newly launched Brabender ExtensoGraph significantly improves dough extensibility assessments, as well as analyses of dough processing properties.

Optimized precision and laboratory efficiency

With an updated operating concept, more precise measurements, more flexible system configurations and a broader range of applications, the new Brabender ExtensoGraph offers several improvements over the previous generation. Compared to the Brabender Extensograph-E, the new model is equipped with a built-in PC and the Brabender MetaBridge software, making it a stand-alone device that requires no external peripherals. Its compact design (see Fig. 1) features an upward-lifting stretching column, designed too not only save laboratory space but also to facilitate flexible positioning in the available workspace. In this way, it stays clear of storage areas and walkways, optimizing workspace use and reducing the risk of accidents. With an adjustable height, the new stretching unit is suitable for very strong doughs (up to 2,000 EU/BU force) as well as especially elastic doughs (approx. 68 cm).

The fermentation chamber, which can be integrated in the Brabender ExtensoGraph or available as an ExtensoFerm module, has also been significantly improved. The chamber, featuring an ultrasonic nebulizer, achieves optimal conditions up to three times faster than the previous-generation technology (see Fig. 2). Temperature and humidity are fully controlled with integrated heating and humidifying systems. Continuous monitoring ensures precise fermenting conditions, with data being automatically recorded. The new chamber design eliminates the need to refill the water containers, which, in turn, means no risk of spilling water.

Fig. 2: Temperature and humidity after startup on the Extensograph-E, ExtensoGraph and ExtensoFerm module

The automation of the work steps in the Brabender

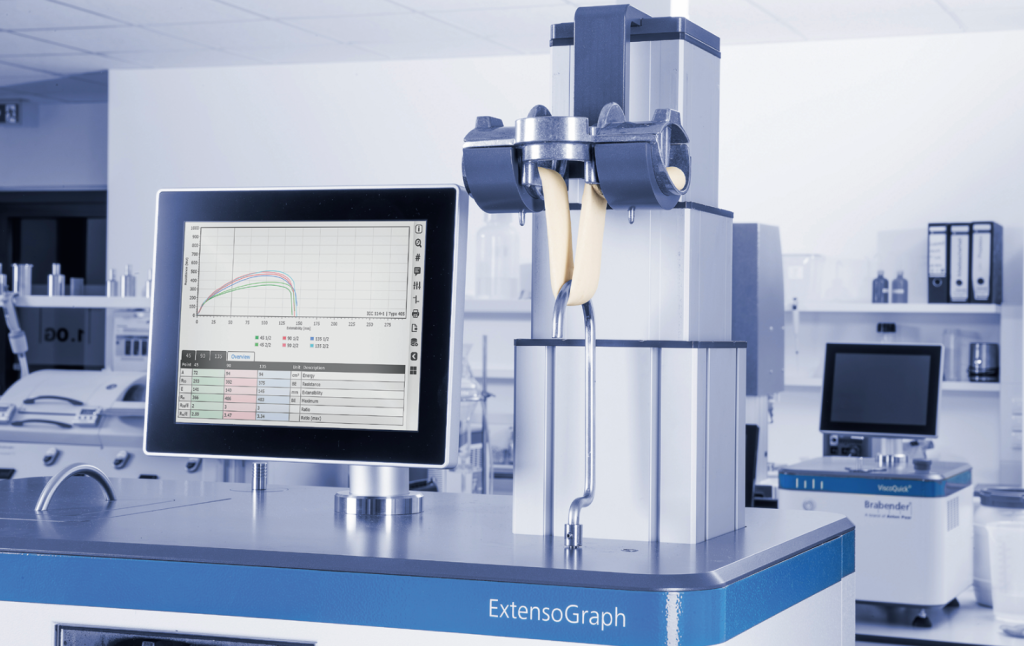

ExtensoGraph covers various stages of dough preparation and measurement, made possible by using light barriers. Dough forming starts automatically when the lid of the ball homogenizer closes (see Fig. 3). The long working process is initiated as soon as the dough sample is detected in the holder (see Fig. 4). Finally, the tensile test starts automatically as soon as the sample is placed in the holder of the stretching column (see Fig. 5). Automating these steps eliminates variability inherent to manual operations, leading to greater reproducibility and consistency of results.

Fig. 3: Dough forming starts automatically when the lid of the ball homogenizer closes

Fig. 4: The long working process is initiated as soon as the dough sample is detected in the holder

Fig. 5: The tensile test starts automatically as soon as the sample is placed in the holder of the stretching column

The modular design of the Brabender ExtensoGraph makes it versatile. Users can choose between an all-in-one system or select individual components tailored to specific needs (see Fig 6). The ExtensoPrep is designed for dough shaping, while the ExtensoFerm is suitable for controlled fermentation, while the ExtensoBase can be used to carry out precise stretching tests. This modular approach allows laboratories to customize configurations based on space availability or the desired throughput.

Fig. 6: The modular units (from left to right), ExtensoPrep, ExtensoFerm and ExtensoBase can be used instead or in addition to the compact ExtensoGraph

Remote monitoring

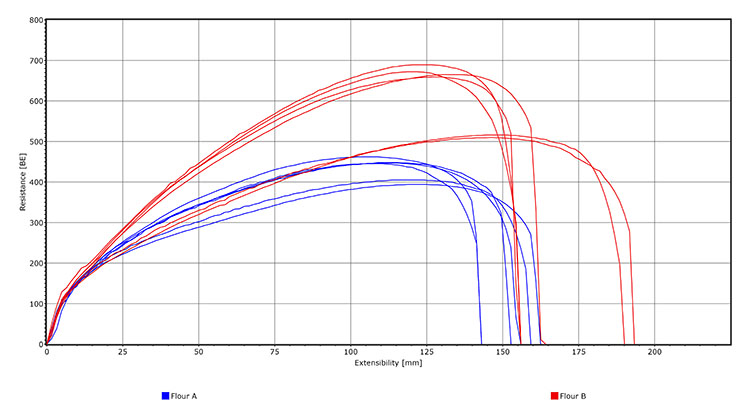

The Brabender MetaBridge software offers real-time monitoring of measurements through any device that can access the internet. Its intuitive interface allows seamless data export in standard formats such as Excel and PDF, facilitating integration with laboratory information management systems (LIMS) and other third-party platforms. The software also features a correlation function that overlays multiple Extensograms to compare variables like fermentation conditions or ingredient ratios (see Fig. 7). This function supports precise data-driven decision-making.

Fig. 7: Comparison of the Extensograms of two flours of different qualities obtained with the ExtensoGraph correlation function

ExtensoGraph vs. Extensograph-E

The Brabender ExtensoGraph follows a rigorous methodology, which ensures reliability and reproducibility. Dough samples are prepared using the Brabender FarinoGraph, which standardizes initial conditions, for consistency across tests. Measurements are taken at three intervals – after 45 minutes, 90 minutes, and 135 minutes of resting time – capturing detailed insights into the dough’s properties over time. Comparative studies confirm that the Brabender ExtensoGraph delivers results equivalent to its predecessor, with significant improvements in efficiency and user experience.

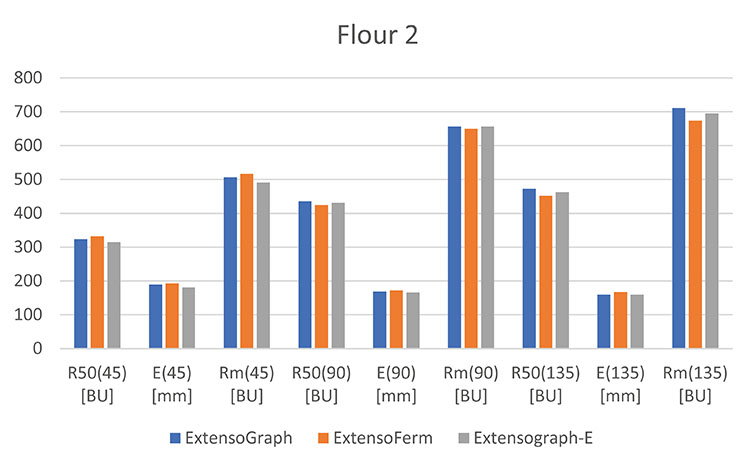

To evaluate the reliability of the new ExtensoGraph in both its compact and modular configurations compared to the Extensograph-E, two types of flour were tested – one with medium and one with high extensibility. All three setups were used, with tests being carried out 12 times for each setup. The results, presented as mean values and standard deviations, are summarized in Table 1, Table 2, Figure 8, and Figure 9. The maximum variations observed among the devices fall well within the typical standard deviation range of the Extensograph method, confirming that the devices deliver consistently comparable results.

Fig. 8: Measurement results of flour 1 (medium-resistant, MR)

Fig. 9: Measurement results of flour 2 (highly-resistant, HR)

Additional applications

Although primarily designed for testing wheat flour, the Brabender ExtensoGraph offers a broad spectrum of practical applications. In quality control, it plays a pivotal role in ensuring consistency across batches, a fundamental requirement for maintaining high product standards in large-scale production environments.

Its correlation function helps to ensure batch-to-batch consistency by overlaying Extensograms from different flour batches for direct comparison. These visual and quantitative analyses highlight deviations, confirm compliance with quality standards, and streamline formulation adjustments, ensuring consistent product performance.

Thanks to the new correlation function, the effects of additives such as enzymes and ascorbic acid can also be precisely analyzed. Extensogram curves of flour samples with different doses of additives can be overlayed for comparison. This visual and detailed comparison highlights the interactions between the additives and the dough qualities. By visually observing the curves, users can assess critical parameters such as dough extensibility, the stretch resistance, and the energy values of different recipes. In this way, the optimum dosage can be determined that will achieve the desired improvements in dough quality.

Matthias Mayser, Department Manager Product Competence Food, Anton Paar TorqueTec GmbH

In addition, the Micro-ExtensoGraph extends the functionality of the ExtensoGraph, particularly for research and breeding applications. With this conversion kit, the sample quantity can be reduced from 150 g to just 20 g. This is especially beneficial when analyzing expensive or limited materials. Despite the small sample, the instrument provides precise results.

Conclusion

The new Brabender ExtensoGraph enables a considerable advancement in the analysis of dough quality and offers precise evaluation means of the dough’s rheological properties – useful information to optimize work in bakeries, mills, ingredient production facilities, as well as research organizations or laboratories.

The automated work steps and the precise control of fermentation conditions ensure consistent results for useful comparisons. Operating errors are also minimized, for increased efficiency.