Bakeries

Sustainability is multi-layered and complicated, partly because it’s difficult to tackle the topic in isolation from other partners in the value chain. Germany’s largest baked goods manufacturer, Harry-Brot GmbH, found this to be true as it has been making strides with CO2 reduction, in-house and along the value chain for years. In this interview, Norbert Lötz, Managing Director of Production and Technology, talks about the challenges and obstacles on the way to sustainable baked goods production.

Interview

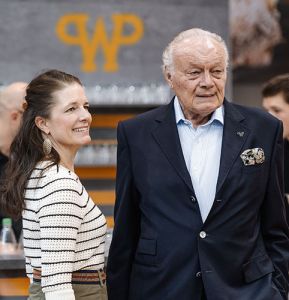

With its portfolio of companies, the WP BAKERYGROUP covers every step of the baking process with dedicated and interconnected equipment. Jürgen Horstmann – owner, Horstmann Group, and Carola Landhäuser – WP BAKERYGROUP CEO, share the insights of leading a diverse group of companies and looking beyond individual production steps when designing solutions, to a ‘think process’ big-picture that shapes innovation in baking.

Visit

The first Lesaffre Baking Center™ was opened 50 years ago, as a place where its specialists could not only put themselves in their customers’ shoes to understand their experiences – from baker to baker, but also roll up their sleeves and bake together to find product and process improvements. Since then, it has become a network of 52 Baking Center™ facilities (and counting), busy baking with manufacturers all over the world, from craft and industrial bakers to baking equipment makers and millers.

Production

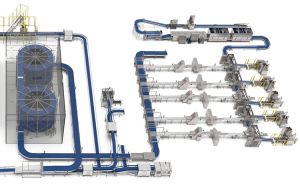

The Kaak DrieM sheeting lines are designed to optimize every step of the process for large-volume dough production. The newest update to the sheeting system can now enable easy access to the portioner for thorough, convenient cleaning and maintenance.

Continuous processes, spirals

Spiral cooling and freezing systems have an unmatched capability to save space. For process consistency, they must also ensure even temperature distribution, and an uninterrupted conveying movement for minimum downtimes, while being easy to clean and maintain. Energy efficiency and scalability features are also important checkboxes for a reliable piece of equipment.

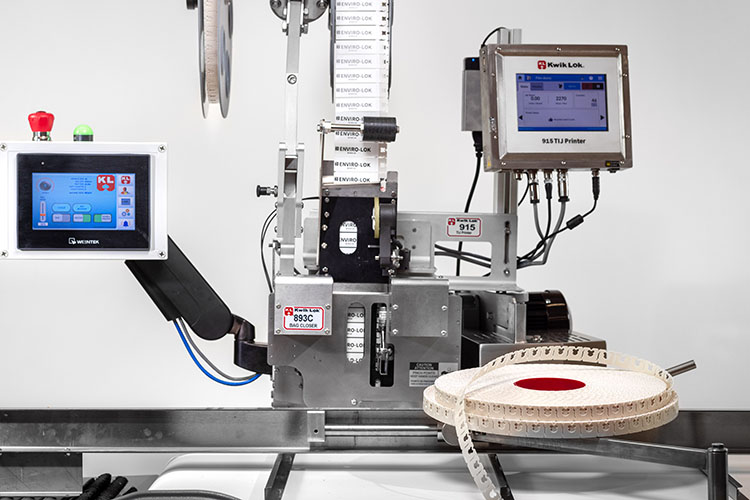

Packaging, coding

Automating packaging and coding not only streamlines the process but also checks all of the boxes – efficiency and transparency, material traceability and sustainability.

Pans

In the world of industrial baking, maintaining line efficiency

and ensuring the longevity of bakeware and their coatings

are paramount to delivering high-quality products consistently.

American Pan’s SMART Pan Tracking® System helps protect the

product and the pan, with actionable information.

Providing excellent-tasting products is a must, but the eating experience is only one of the goals for successful snacks. The challenge lies in balancing health benefits, clean-label compliance, and manufacturing efficiency – all while meeting consumer expectations.

packaging

Sustainable packaging in the bakery sector lies at the intersection between EU regulations and industry commitments.