Bundy Baking Solutions is the USA market leader in the area of trays, pans and coatings. The American company, which also produces mixers (Shaffer), for example, would like to develop new markets and make further investments.

Bundy Baking Solutions currently employs a workforce of around 1,000. Purchased acquisitions in 2017 alone brought in around 300 new employees. For example, the Group took over the FBS Prestige company in Great Britain in 2017. The agreement comprised the acquisition of three coating plants in Great Britain together with a production facility in Romania. Gilbert Bundy, CEO of Bundy Baking Solutions, added this explanation: “Combining the innovation and market knowledge of American Pan and FBS Prestige excites us greatly. It results in the optimization of two industry-leading companies, and the opportunity to provide a fast, comprehensive tray and coating service to our clients in Europe and the Middle East as well as North Africa.” The CEO also explained that “Bundy Baking Solutions plans to make significant investments both in the fabrication business and in the coating business.” CEO Gilbert Bundy confirmed that a lively exchange of experience and view already exists between the factories in the USA and the works in Romania.

The brands of Bundy Baking Solutions

+ American Pan

+ Chicago Metallic

+ DuraShield

+ Pan Glo

+ RTB

+ Shaffer

+ USA Pan

+ American Pan UK

+ American Pan SE

Export market

Bundy Baking Solutions is considered to be the clear USA market leader in the area of trays and pans. CEO Gilbert Bundy explains that “Like our customers, we grow globally.” The company’s export ratio six years ago was still around 15%. Referring to the growth strategy, the CEO says “Today it is approx. 50%.” Bundy Baking Solutions manufactures trays, e.g. for hamburger buns, and cake tins, as well as the matching coatings, under the brand name American Pan®. Altogether there are 26 agencies worldwide – from Urbana, USA, and Baura, Brazil, to Nottingham, UK, and Alexandria in Rumania.

The company offers a comprehensive spectrum of services in the trays and pans area. For example, customers can arrange for trays to be collected. Where necessary, the trays are straightened/repaired, cleaned and recoated, e.g. with AMERICOAT® Plus silicone release coating.

This cleaning, straightening and recoating service is also available for baking pans (e.g. pans with the non-stick coatings American Pan DuraShield®, OptiShield or Excoat from Excellent Coatings). At least 3,000 baking cycles are guaranteed for the leading DuraShield coating for most products, and more than 5,000 baking cycles have been documented by a few leading global bun bakeries.

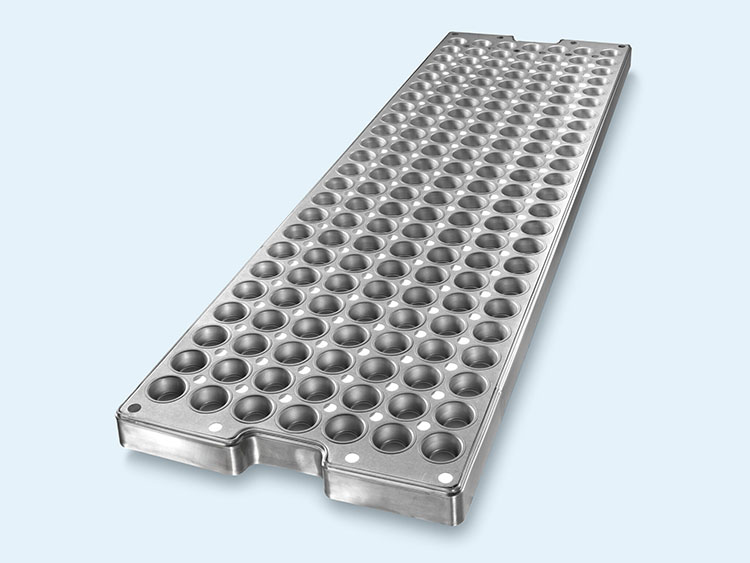

In addition to its coating and maintenance service, the company also offers customized industrial baking trays. Jason Tingley, Vice President of American Pan and responsible for design, technology and innovation, explains that American Pan’s corresponding fabrication, design and highly-developed machining capabilities enable the company to produce individually customized baking pans that can fulfill any bakery’s requirements. He also says American Pan’s baking trays and baguette pans can be designed to any size and used in any industrial oven system. They can be supplied stackable and with the exclusive TabLock design, which uses a patented system to fasten the baking surface into the frame without requiring rivets or welded seams. The company also offers the American Pan® SMART Pan Tracking® system. This involves using a laser to engrave a code and number onto the tray or pan. The code and number are linked to a bakery-specific database containing information about the pan type, dimensions, size, expected lifetime of the coating and number of baking cycles per pan. Sensor technology is integrated into the bakery’s production lines to record each pan and transmit the data to a secure web site which the customer can access. According to American Pan Vice President Jason Tingley “The system records the data very precisely and prepares analyses for the bakeries, e.g. to monitor the lifetime of the coating, line efficiency and numerous other important process parameters.” For example, the system can detect and analyze the number and length of gaps between pans. Optimum plant capacity utilization can increase the throughput of baked products.

There are continuous improvements in the silicone and Teflon coatings for trays and pans, and the shape of the trays is also being optimized. Bundy explains “For example there is the E-Pan, which depending on the pan is 30 to 50% lighter and at the same time more sturdy than comparable pans.” At present, customers generally prefer to order large trays and pan clusters. The CEO promises that the new design will be exhibited at the iba trade fair.

Gilbert Bundy, CEO of Bundy Baking Solutions

Jason Tingley, Vice President of American Pan

Andrew McGhie, Sales Director for Shaffer Mixers

Shaffer Mixer

Andrew McGhie, Sales Director for Shaffer Mixers, will also present innovations in the mixing and kneading area at the trade fair in Munich. The Group is making big investments in Research and Development for this. McGhie promises “In the mixer field, the engineers are currently developing many innovations in the Hygienic Design area, and these will also be on show at the iba trade fair in Munich.” For example, the bowl cooling jackets have also been reengineered to allow dough to be cooled more uniformly and faster and to control the dough temperature even more accurately.

In this respect, the VerTech™ cooling jacket was designed specifically for kneading machines and a patent filed for it. Shaffer Mixers guarantees a five-year warranty on the new cooling jacket, which is said to operate using glycol. Andrew McGhie explains that “The VerTech™ cooling jacket also needs less energy to circulate the coolant, without reducing the effective heat transfer, thus ensuring maximum cooling. The energy saving is noticeable with every dough batch processed in the mixing machine.” Other topics include an improved plant hygiene design and the restriction of downtimes to a minimum. Shaffer also offers roller-bar, single-

sigma, double-sigma and other mixing machines in a large number of sizes designed for the specific needs of each product and each plant.

According to CEO Gilbert Bundy: “Whether it’s improvements in hygienic design in plant construction or the development of new trays and pans, Bundy Baking Solutions’ customers motivate the whole Group to develop innovations in all areas.” He says the company wants to continue growing globally through these innovations and ideas.