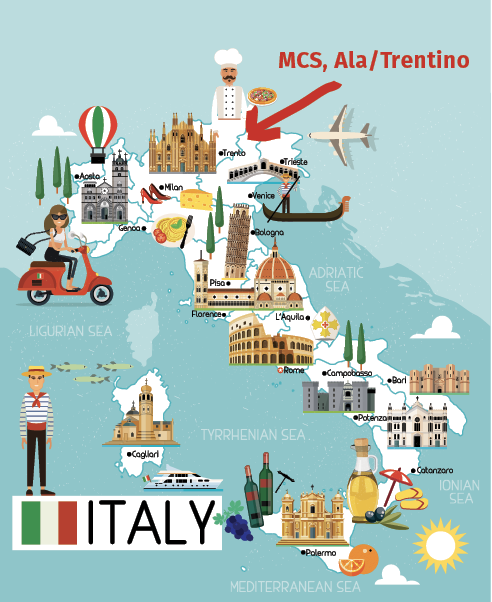

Pizza production is one of the key points of expertise of Kaak’s Italian MCS subsidiary from the northern Italian commune of Ala. The Italians’ latest highlight is a new, fully automatic pizza press.

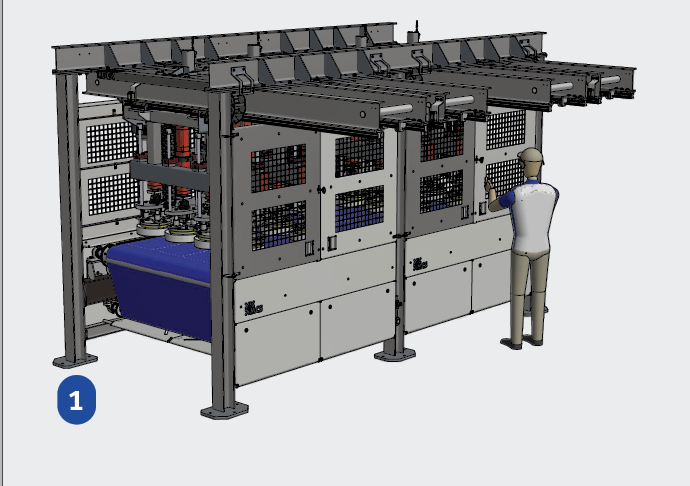

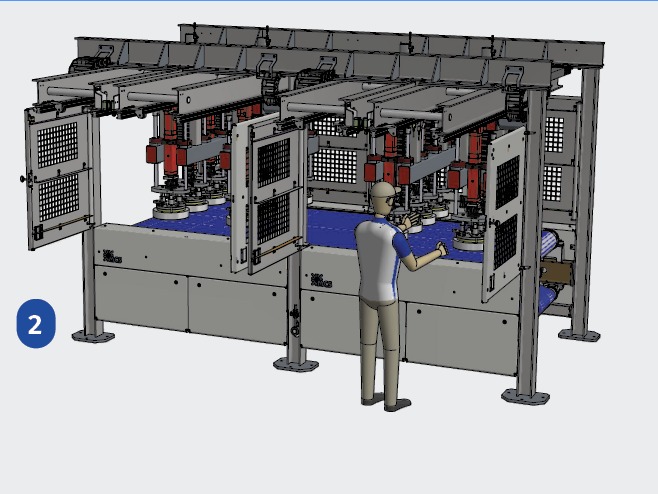

The press can be pulled out sideways so that changes in format, as well as cleaning and maintenance, can be done easily and quickly

Pizza crusts can be made in two ways. They are either cut out of the dough sheet, or a ball of dough is pressed into a round disk. The latter is considered the more sophisticated process because it at least comes close to a pizza chef’s manual production method. Due to the round molding of the dough ball and the period of rest that may have preceded it, this process also achieves a classic pizza dough structure and the edges are closed, as with a hand-formed dough crust.

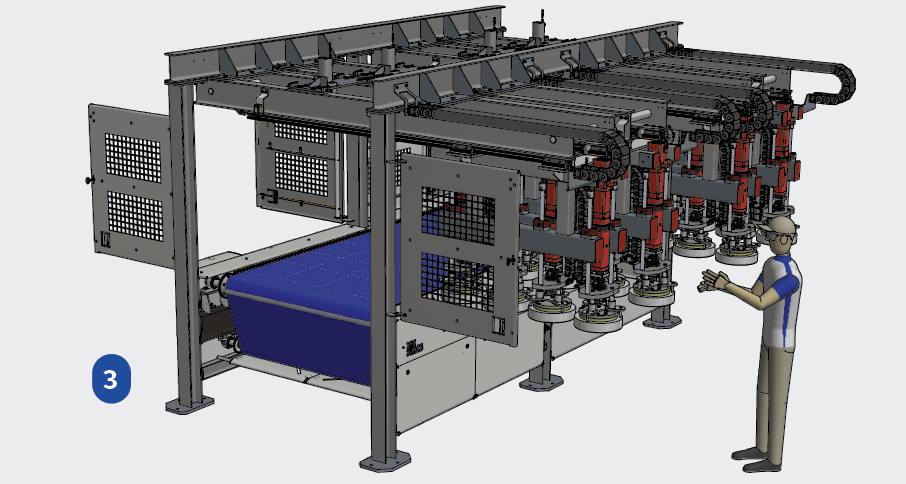

Nevertheless, different procedures also exist for stamping out pizza crusts. One can, for example, let the stamp act on the dough hot or cold. The dough can be pressed into a mold, or on a belt. The new pizza press from Kaak’s MCS subsidiary can do all of that, hot and cold, and either in a mold or on a belt.

The press tool can be adapted to every requirement according to product size, profile and thickness, as well as to press parameters such as speed, force, time and temperature. Each individual press head is driven by servo motors, while each press punch can be coated for pressing with or without oil. In addition, the product’s top and bottom heat can be controlled just as precisely as all the other press functions. If the dough is to be shaped especially gently, one can also press sequentially, i.e. in several small pressure sequences, until the dough has attained its final shape and size. Ala’s engineers have paid great attention to the system’s hygienic performance. The press can be pulled out to the side so that changes in format, as well as cleaning and maintenance, can be made easily and quickly. The entire construction is of stainless steel. It is robust, hygienic and available in a wash-down version.