Wolf ButterBack KG, a premium frozen baked products manufacturer in Fürth, is growing dynamically and is investing around EUR 50 million in a new third factory. The company had to expand production capacity to meet rising demand.

Wolf ButterBack KG, Fürth, has grown very dynamically in recent years. The company was founded by master baker Erwin Wolf in 1992 and in the year 2000 it moved over the nearby city boundary from Nurnberg to Fürth, where Factory 1 was built on a green field site. Around 50 employees manufactured premium-quality frozen baked products, mainly for the baking sector. For reasons of age, Master Baker Wolf sold the company in 2004 to Martin Braun and thus to the Oetker Group. This was followed by further dynamic growth and the construction of Factory 2 in 2005, again on the Magazinstrasse site.

Approx. 550 staff are currently employed. The plan for 2019 is to have around 600 employees working for the company. This is possible because Wolf ButterBack has invested around EUR 50 million in Factory 3, and has enlarged the Magazinstrasse site. Ernst Stengel, Executive Board Member responsible for Production and Purchasing, has looked after the new building from the first to the last second. Stengel explains: “After an intensive 18-month construction period, our Factory 3 came on stream in April.” The new building has three stories. Two new production lines are already operating. One more plant will follow, and altogether the factory has capacity to install six production lines. The company also invested in a new, fully-automatic computer-controlled high-bay deep-freeze warehouse more than 42 meters high, with space for 8,700 pallets.

Energy efficiency

Ernst Stengel explains: “Of course, important aspects such as energy efficiency, production safety / security and a responsible attitude towards climate and the environment were taken into account when enlarging the site. For example, part of the electric power in Factory 3 is generated by a fuel cell. This is already the company’s second, and the resulting oxygen-

depleted vent gas (reduced to approx. 11%) is re-used as fire protection in the high-bay warehouse. Modern technology is also used for heat recovery, in which the entire waste heat from the refrigeration systems is used as process heat, e.g. in fermentation chambers, to produce hot water and to heat the premises. Likewise, a new central biological wastewater treatment plant for the whole site was installed. Of course, we use natural refrigerants such as ammonia and CO2 in the refrigeration systems. According to Stengel: “When planning Factory 3, we took care to ensure we can achieve an overall doubling of the existing production capacity. The building, the technical services supplies and even the refrigeration plants are already prepared now for further growth.”

The company’s location also has space available for an additional building extension. With today’s dynamic growth, the Executive Board estimates that this extension – Construction Phase 2 – might take place in the mid-2020s. Marketing and Communications Manager Tanja Böttcher explains: “We have recorded high single-figure growth for a number of years.”

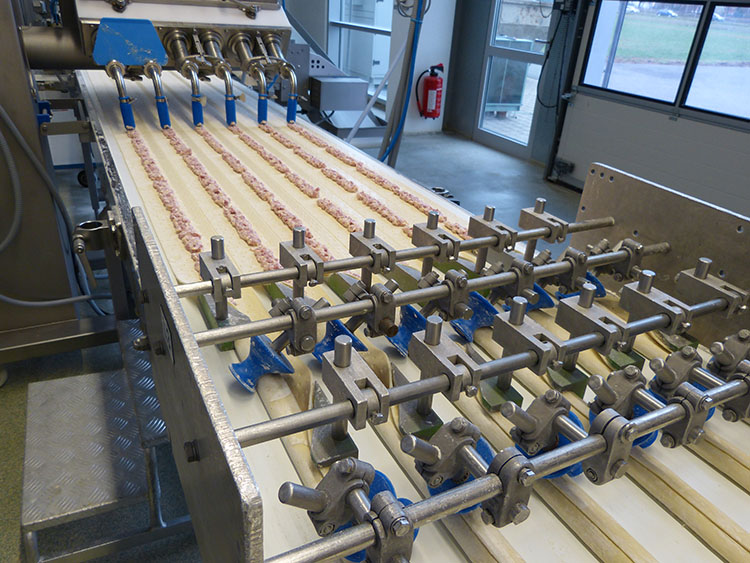

Laminated doughs are cut, deposited onto trays then carried on rack trolleys to the cooler, where the dough rests for up to eight hours

Factory 3

January 2015

Acquisition of the neighboring 15,000 m² site

Total site area: 32,000 m²

November 2016

Start of construction, Factory 3

First construction phase, three-story for up to six production lines

High-bay warehouse 2 with 8,700 pallet storage spaces

Height: 42.5 m

Since 09.04.2018

Trial operation on two lines

Since July 2018 onwards

Production goes live

The two production lines currently in Factory 3 for high sales volume sweet or savory filled products. Up to six production lines are possible in the first construction phase

Electricity is generated by a fuel cell

Use of the oxygen-depleted exhaust gas (11%) as fire

protection in the high-bay warehouse

Central biological treatment for wastewater from all three factories

A system to separate wastes into biowaste, film, metal, paper and residual waste

The site

Bridges and conveyors interconnect all three factories.

A one-way traffic system operates on the crossings between the factories. Up to eleven trucks can be prepared for dispatch simultaneously, and six truck maintenance bays are available. An amenities room with sanitary facilities for truck drivers has also been installed

Outlook

Jobs for up to 700 staff are planned at the site.

Construction Phase 2 is being planned.

Wolf ButterBack employees make almost all the fillings for baked products themselves, e.g. fruit or nut fillings, as well as savory fillings

There are now three factories at the site, each autonomous and with its own flour and sugar silos

The staff also produce deep-fried pastries

History

13.01.1992

Wolf ButterBack founded by Erwin Wolf with one employee, Dagmar Kreis. Rented premises, approx. 200 m² on the site in Geuderstrasse at Stein near Nurnberg

December 1992

Relocation to Stein / Wilhelmstrasse, production area 600 m²

01.01.1994

Expansion to Nürnberg / Gebersdorfer Strasse, 1,300 m²

September 2000

Move to the new building in Fürth, and closure of all the old sites

Site area 7,210 m² with 9,800 m² of space usable for production and administration, and a refrigerated warehouse for 1,100 palettes

December 2003

Neighboring plot of land, approx. 10,000 m², purchased to enlarge the company

01.01.2004

Erwin Wolf retires from the business on age grounds and sells the company to Martin Braun KG

20.06.2005

Construction of the extension building (Factory 2) starts at the Fürth site, Magazinstrasse 77

Building area 8,500 m², refrigerated warehouse for 2,500 palettes

03.04.2006

Bringing Line 1 into operation in Factory 2

August 2006

Commissioning the deep-fried pastry plant for butter donuts

April 2009

Building starts on enlarging the refrigerated warehouse to add 2,500 more palette spaces and to expand the order-picking zone

June 2010

Commissioning the enlarged warehouse, which now has a total of 5,000 palette storage spaces

September 2012

Renewing the refrigeration plant in Factory 1 to use natural refrigerants such as ammonia and CO2

January 2015

Acquisition of the neighboring 15,000 m² plot of land

June 2016

Completion of the amenities building for up to 800 employees

November 2016

Work starts on Factory 3, first construction phase for up to 6 production lines

High-bay warehouse 2 with 8,700 palette storage bays

Height: 42.5 m

State-of-the-art heat recovery technology, and exclu-

sive use of natural refrigerants (CO2 and NH3)

Around 1.4 million dough pieces already leave the production facility every day, for which the employees process around 28 tons of butter and approx. 60 to 70 tons of flour on a total of 13 lines. This involves producing sweet and savory dough pieces, of which slightly over 30% are exported. Bakeries are the main customers in Germany, but in the neighboring countries, in Russia or in Japan they also like to rely on dough pieces from Fürth. All the channels such as hotels, filling stations and the food retail are served here.

Despite all the automation, operations at Wolf ButterBack are personnel-intensive: quark turnovers, for example, are made up by hand, and chocolate-vanilla coiled products are bent by hand before being carried into the freezer

Production

Wolf ButterBack has always been committed to using high-quality ingredients, e.g. pure diary butter and a long dough resting time of up to eight hours, to produce high-grade frozen dough pieces with the required quality. All the products from the foundation era are still in the program today, and Wolf ButterBack currently has more than 150 unfilled, sweet and savory dough pieces as well as donuts in its standard product range. According to marketing expert Tanja Böttcher: “Altogether, however, we have around 650 products in the sales range.” Explaining the assortment, authorized company signatory Ernst Stengel says “In addition to our own products in a wide variety of weight ranges and different variants, we also manufacture dough pieces using customers’ own recipes.” Standard procedure for all laminated doughs – regardless of whether they are produced in Factory 1, 2 or 3 – is that the doughs are cut after laminating. After that, the staff put the pieces onto a tray and into a numbered rack trolley. This rack then goes into the cooler, where the dough can rest. Stengel says “This ensures more aroma and flavor, and thus premium quality.” It also guarantees product traceability.

Basically, all the factories are autonomous. They each have their own flour and sugar silos, and can be operated independently of one another. Of the three, Factory 1 with six production lines specializes in smaller batch volumes and on high-end products involving a large skilled labor input.

Staff manufacture high sales volume products on the four production lines in Factory 2, e.g. unfilled or sweet filled croissants. The medium-term plan is for Factory 2 to make exclusively unfilled products. It is also the location of the plant manufacturing butter donuts.

Factory 3 makes high sales volume products with sweet or savory fillings and currently has two production lines, although the first construction phase has the capacity to install up to six production lines. According to Stengel: “The start of construction phase two is scheduled for 2025 onwards.”

For the production plants in the newly-built factory, Wolf ButterBack also focuses on state-of-the-art technology, including in relation to servicing and maintenance. This is why the company cooperates closely with plant constructors, e.g. by using prototypes such as automatic final position detection for croissant dough pieces.

Executive Board Member Ernst Stengel says the factories’ capacity utilization is good, although still with room for further growth. What the experts are more concerned about, however, is fluctuating raw materials prices, especially for butter, but the company’s position is altogether satisfactory and it is fit for the future.