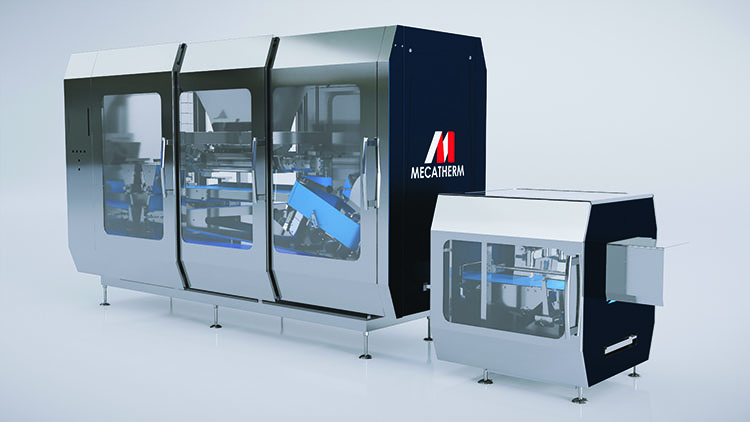

Mecatherm has developed a new dough divider, the M-NS, presented for the first time at the 2018 iba trade fair.

The new M-NS dough divider is compact and enables even doughs with a high dough yield and long resting times to be divided, molded and deposited into pans. The dough pieces can weigh from 100 to 900 g

Mecatherm’s new Type M-NS dough divider model operates volumetrically. The plant is compact and can divide and mold even doughs with a high dough yield and long dough rest times and can deposit them, e.g. into pans or pan clusters. Dough pieces can weigh 100 to 900 g and the plant achieves an hourly output capacity of up to 2.5 tons of dough. According to the manufacturer, the divided dough pieces are not subject to any stress. Mecatherm says the combination of stress-free dough pieces and subsequent molding ensures that the end-product shows improved oven spring and develops a thin, non-dry crust together with a light, fluffy crumb, just as a French baguette should be.

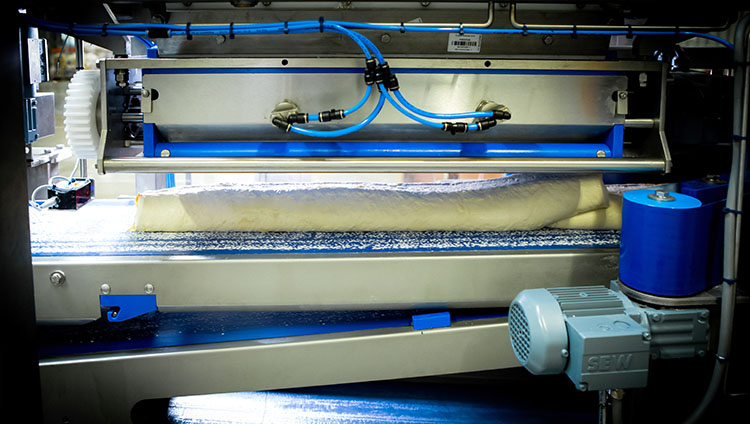

The M-NS dough divider needs no molding machine, laminating roll or multi-roll. The division process starts once the dough is centered. After being divided, the individual dough pieces are separated and their weight checked. If the latter does not agree with the target weight that was set, the dough piece is rejected. The density of the dough is also calculated. The manufacturer promises that the weight of the dough pieces always remains identical, irrespective of dough density. It also says the system responds automatically to dough density changes, e.g. in the event of a production interruption.

The machine is operated via a display, where the operator simply enters two values: target weight and deviation tolerance. The dough divider does everything else automatically, and even independently resets itself if deviations occur. Its good accessibility and easy cleanability are also beneficial. The new dough divider is EHEDG-certified (EHEDG: European Hygienic Engineering and Design Group), so it conforms to the hygiene criteria specified by the EHEDG. Moreover, it is said that the dough divider can also be integrated into existing production lines.