Lhotellier R2A, a subsidiary of the Kaak Group in the Netherlands, has developed and marketed non-stick coatings for the baking sector since 1963. Experts provide support when choosing optimum non-stick and de-panning coatings.

Lhotellier R2A is considered to be a specialist for tray and pan cluster cleaning and (re )coating, since this Kaak Group company has developed and marketed non-stick coatings since 1963. In this respect, Lhotellier R2A offers a wide selection of different coatings to guarantee optimum de-panning with any product and every kind of pan. The company promises that greasing becomes wholly or partly superfluous, depending on the coating and product. These coatings are suitable for all types of materials, and satisfy the European Directives for products that come into contact with foodstuffs.

Lhotellier R2A constantly researches and develops novel coatings for a wide variety of applications in the baking sector

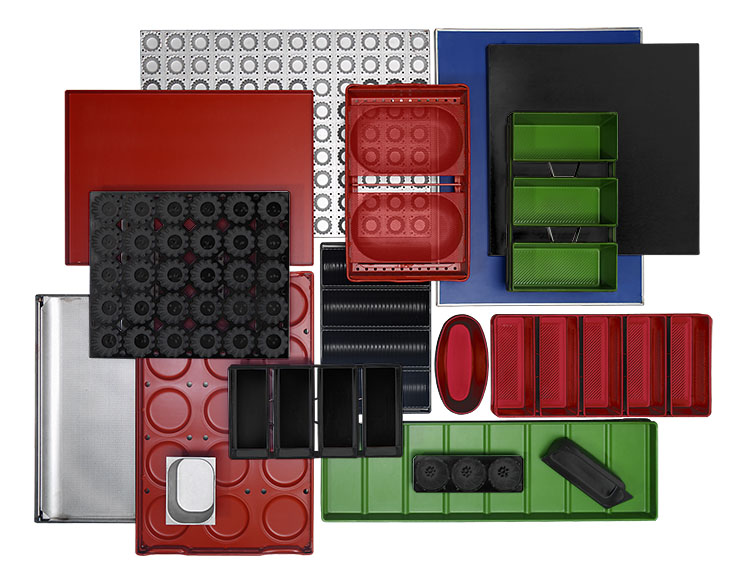

A multi-layer system

The coating for pan clusters or trays is applied by means of a multi-layer system. The surface texture is of the greatest importance to ensure a strong bond with the coating. Therefore the first step in the coating process is thorough cleaning of the surface. After this first step, a primer coat is applied to maximize the bond between the pan and the non-stick coating. Depending on the specification, this is followed by the application of one or more coats with specific de-panning properties. Finally, the coating is sealed, creating a uniform, hard-wearing coating with corresponding proofing, baking and de-panning properties. As a rule, the outer surface of the pan is given a black enamel coating to ensure optimum heat transfer.

The company offers the following coatings:

Multi-Flon®: According to information from the company, a Multi-Flon® fluoropolymer coating provides a high degree of resistance against abrasive wear, chemicals and rusting.

The iBakeware® detector system reads the ID (identification) code on trays or pans, thereby recognizing which product carriers need recoating or replacement

Multi-Sil R®: According to Lhotellier R2A, the Multi-Sil R® rubber-silicone coating is suitable for baguette baking trays and for applications involving sweet dough.

Multi-Sil G®: The Multi-Sil G® coating is said to be especially suitable for very viscous doughs or batters such as cake dough, but is also frequently used in the production of bread and confectionery.

The company constantly carries out research on new coatings, and as Bruno Servant, R&D Manager for Lhotellier R2A, explains: “Optimizing our coating is a continuous process. That’s logical, since our customers increasingly seek perfection.”

As well as consultancy and cleaning & (re-)coating trays and pan clusters, the company also offers the das iBakeware® detector system. This system uses an ID (identification) code located on the product carriers, i.e. on trays or pans. The Kaak ID system scans this ID code and can thus recognize which product carriers need to be recoated or replaced