Rademaker has developed a new pastry production line. The Universal Pastry Line with its newly-developed controller can produce a wide variety of dough pieces highly flexibly. Its construction is modular, and a well-thought-out tool concept ensures fast product changeover.

Ability to perform meets quality – that’s the motto of the new generation of production lines from the bakery equipment manufacturer Rademaker. Specifically, it involves a newly-designed production line (Universal Pastry Line). The Netherlands-based company sees potential for the new line, which is designed for industrial operators and medium-sized companies, especially in the European and North American markets. That’s also why Rademaker is showing the machines at the IBIE trade fair in Las Vegas and the südback trade fair in Stuttgart.

Operation 24/7

Explaining the design concept of the new generation of production lines, Paul Groenewegen, Managing Director of Rademaker Germany (which also serves the Austrian and Swiss markets) says: “In their design, we took special care to ensure the production lines have very good accessibility to make cleaning and maintenance as simple and easy as possible, and we maintain the highest hygiene standards.” Stainless steel, smooth surfaces, a rounded frame and the use of materials approved by the FDA (U. S. Food & Drug Administration/the US foodstuffs and medicines authority) guarantee that the machines are easy to clean. Paul Groenwegen goes on to explain that “The Universal Pastry Line has no recesses, cavities or dead zones, and it goes without saying that this new Rademaker production line is entirely designed and approved for wet cleaning.” The belts are also equipped with quick-release devices, the belt tensioning rollers are massive, and all of the machine’s bearings are located externally. The machines are designed to operate 24/7. Moreover, due to the high in-house production ratio of around 94%, Rademaker also ensures that the customer’s high quality demands and a problem-free spare parts supply are guaranteed.

A new tool concept

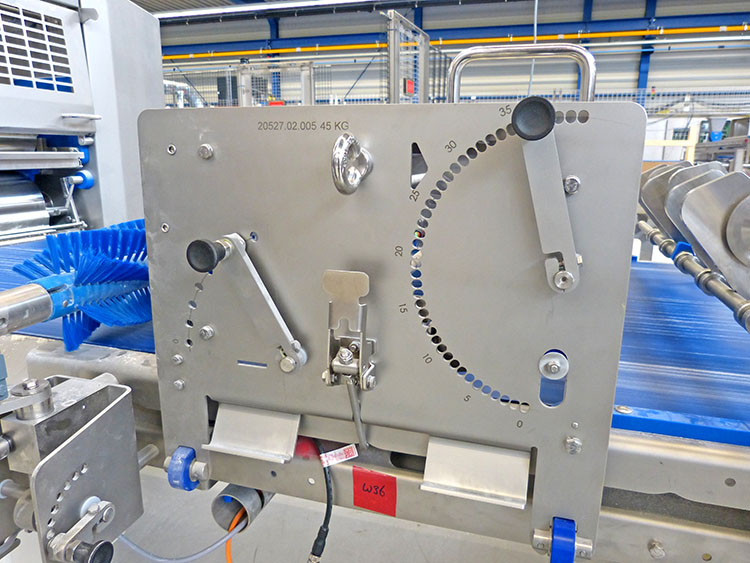

When developing the production line, the designers considered it important to enable tool-free component and tool exchange. In the tool design concept for the latest generation of machines, each tool and every part of the machine has an individual identification number. According to Paul Groenewegen: “The tool assistant developed by Rademaker, which we call Tool Assistant, simplifies operating and retooling plants.” Tool Assistant stores individual tool and line configurations. Thus line settings are reproducible, e.g. when there is a product changeover, and users can understand and access them easily. All the line and tool data can be exported to the control panel or a tablet, or as a printout. Pop-up windows in the control panel explain to the plant operator which settings and process steps must be carried out. The control system is displayed on a 22-inch adjustable-height touch-panel. Access is password-protected, e.g. for recipe management, and there is also an option to access by chip.

The new machine has fewer drives compared to other plants. Nowadays, instead of up to 20 motors/drives, only seven or eight per plant are needed. This is noticeable in the form of lower maintenance costs, for example. Users need to stock correspondingly fewer spare parts. As Groenewegen explains: “The subject of preventive maintenance plays an important role for Rademaker, so we prepare an individual kit of spare parts for each new plant, which the customer can keep in stock.”

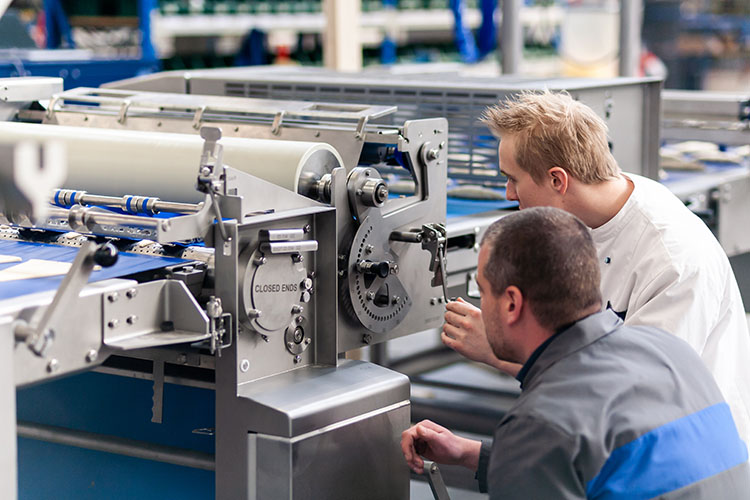

R&D Manager Jan van de Grift (l.) and Managing Director Paul Groenewegen

Rademaker’s consistent emphasis on the “identical parts concept” in relation to spare parts also reduces the user’s stock-holding costs. Rademaker BV’s R&D Manager Jan van de Grift adds “We use standard components if it is possible for us to do so, but of course we add specific tools and designs to our machines in accordance with customers’ wishes. For us, this is a challenge we gladly accept.” Van de Grift played a key role in developing the new line concept, including implementation of the new controller. “We know how important an intuitive controller is in practical terms. It must be easily understandable, safe and secure. This is ensured by the novel cascade controller we have developed, e.g. with dough output (loop control) and dough input (DDIC) monitoring, together with a dough presence monitor,” explains Jan van de Grift. “This leads to improved product quality and greater operational reliability,” adds Paul Groenewegen because, for example, the new controller specifies which dough the operator must prepare and/or process next to make optimum use of the line, so the production facility will have the best possible capacity utilization.

Flexibility

As Groenewegen explains: “Simplified operation, improved process control and lower maintenance costs compared to other models lead to a considerable reduction in operating costs, and support the efficient use of personnel.” Moreover, the cascade controller allows the production line to operate in sectional mode, or even automated modular operation, to increase the production facility’s flexibility. Thus the controller provides an increase in the machine’s capacity utilization, while simplifying operation at the same time.

The fact that the new Universal Pastry Line’s modules are interchangeable also makes this possible. Components such as the fat pump were also re-engineered. This enables different fats such as butter, margarine or clarified butterfats to be processed as needed. Horizontal and vertical screws with a molding function in the new, reengineered fat pump ensure a continuous flow of fat is applied to the dough sheet. Sensors supervise the process and ensure constant pressure

monitoring. The fat pump is also mobile and can be removed from the production unit, e.g. for cleaning. The designers also took care to ensure that the fat pump can be dismantled and cleaned easily. According to R&D Manager Jan van de Grift “We are also confident we have the most accurate fat pump on the market, and errors are less than 1%.”.

Each tool and machine component is given a name and a unique identification number. These allow a user to know which tool he/she should use when there is a product changeover

Fat pump data

+ Fat pressurizing is monitored by a sensor, thus preventing unwanted heat input, and lamination takes place more cleanly

+ The fat layer is applied across the entire working width without any dead corners (hygienic design) across a 270 mm width

+ Options to adjust the fat layer thickness of the applied fat layer (dough/butter ratio)

+ Accurate weights through minimal tolerances of below 1% – depending on fat type and temperature

+ Friendly cleaning opportunities through good accessibility to the entire fat pump

With the new production line, Rakemaker offers a choice between various different lamination methods to cater for customers’ requirements and requests. As Paul Groenewegen explains: “This is how we support customers to find the best lamination method, which depends on the required capacity and type of dough being used.” For example, the overlapping method is suitable for stable doughs (lamination width 600 mm). The horizontal lamination method is also an option for softer doughs (lamination width 600 to 1,600 mm), while the “cut-and-stack” method is the most flexible system with regard to the number of fat-dough layers, and can be used to laminate both rather firm and rather soft doughs. The lamination width when using these methods is between 600 and 1,600 mm.

Rademaker laminators also allow a dough cooling and resting section to be installed. With the Universal Pastry Line, dough resting times up to 2.5 hours are achievable in this way. “The engineering and technology for this system were developed by Rademaker, and it builds them itself. A very large volume of experience and know-how in this area has been accumulated during the past approx. 30 years. The cooling process ensures that the dough and fat layers remain intact in laminated doughs. This leads to a considerable improvement during the downstream processing of the dough sheet,” according to Jan van de Grift. To which Paul Groenewegen adds “But even for products that are not laminated, the rest time ensures dough relaxation and thus the best possible flavor and a trend to larger baked product volumes.” In relation to the cooling and resting section, the new controller also calculates that the timing, i.e. time and belt speed, are optimally coordinated to one another in order to guarantee high capacity utilization.

Intuitive cascade control design allows the plant to operate sectionally, while an intelligent controller gives support during production, retooling and cleaning

Rademaker’s new Universal Pastry Line now enables (semi-)industrial and in-store bakeries to manufacture all kinds of baked and laminated products in any size and shape, filled or unfilled. Hourly capacity is from 350 to 1,500 kg of dough. The company says a significant reduction in operating cost is also possible. This is achieved by improvements such as efficient, error-free tool change, a low level of maintenance and simplified, intuitive operation. Moreover, Rademaker is confident that hygienic machine design has been raised to a new level. Modular construction also ensures flexibility, and single plant components, e.g. a mono-pump metering machine with an individual single-series controller is possible at the customer’s request. Furthermore, the new plant’s controller is undergoing further optimization, for example the flour dusters, which can be cleaned in a dishwasher, allow synchronization of the new pastry line plant to achieve a high output capacity and great production flexibility.