Consultant Thomas Ismar of Zeppelin Systems GmbH says: “We haven’t re-invented bun production, but we have made it more efficient and more flexible at the same time.”

Flexibility already begins at the dough preparation stage. The line evolves around with a continuous mixing system from the CODOS® series that can either supply straight dough or can also operate on the sponge&dough principle.

The CODOS®, following more than 100 plants now in service in baked goods production worldwide, got an all-round makeover last year with new drive technology, new cooling, Washing in Place, and also a new controller that communicates with Zeppelin’s higher-level automation and digitization software. So Zeppelin created the new CODOS® NT.

The previous asynchronous geared motor has been swapped for a water-cooled servo drive with a single reduction gear, which means not only a 40% weight saving but also a reduced installed length, i.e. space is saved, and on top of that energy consumption is reduced.

The cooling system of the CODOS® NT has also been fully redesigned. The efficiency level of the trough cooling has been improved considerably, which ensures better heat transfer. All the trough cooling assemblies will be positioned outside of the new continuous mixer in future.

Moreover, with assistance from research work at the Cereals Research Institute IGV Foodtech in Rehbrücke, Germany, the geometry and spacing distances of the mixing tools themselves have been optimized again. According to Michael Piepenbrock, Zeppelin’s Business Unit Manager, Food Processing Plants: “That provides more power and performance with less energy consumption, and makes the CODOS®scalable.” There will be a CODOS® NT 160 with a dough production capacity of approx. 3 tons/hour, the CODOS® NT 200 at 4 – 5 tons/hour and the CODOS® NT 230 with up to 8 tons/hour of dough. In 80% of all cases, a CODOS® stage will be combined with a DymoMix that supplies pre-mixed, uniformly wetted raw materials to the CODOS®. A two-stage CODOS® solution is usually used when processing flours containing extremely high gluten levels.

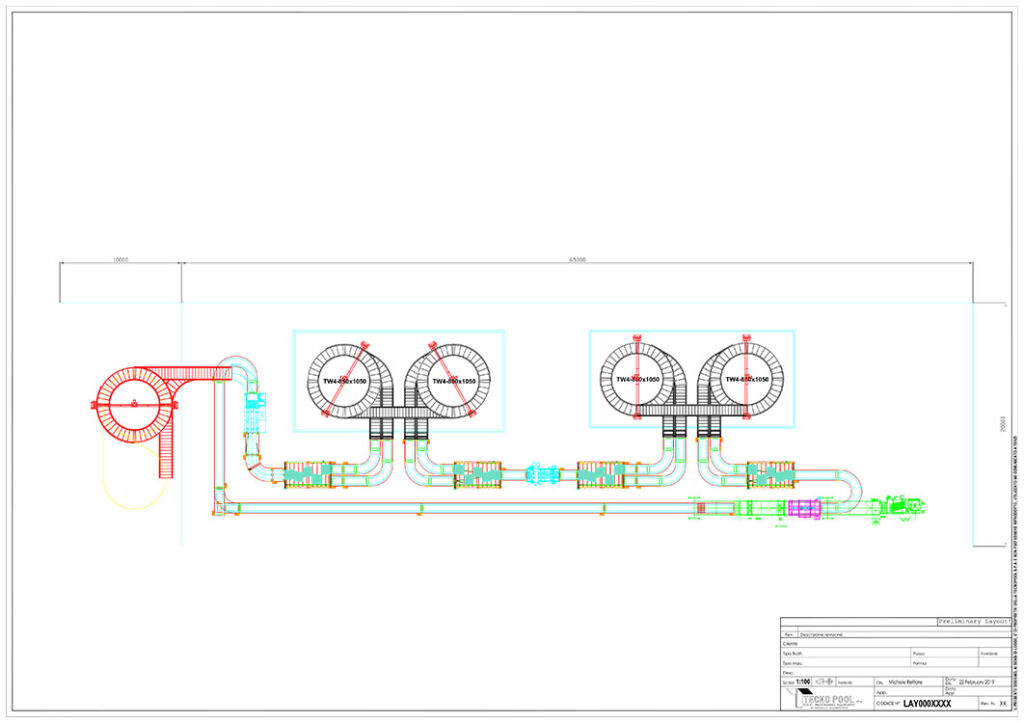

Layout for a bun line with an hourly capacity of 3,000 pieces per hour. The biggest line designed up to now delivers up to 60,000 buns/hr

The sponge&dough principle involves installing conveyor belts between the sponge dough preparation stage and the final mixer, on which the sponge dough can rest and ferment while being conveyed, for up to 24 hours if required.

The conveyor belt adjusts to the required resting time, and can accommodate up to 9 tons of dough. According to Ismar, four hours of fermentation are normally suggested for buns. A mixing capacity of 4 tons/hour of sponge&dough would need a transport unit 20 m long, 6 m high and 4 m wide. However, not only does the space requirement turn out to be modest, the investment budget for the fermentation stage also remains very manageable at EUR 0.5 million. Ismar says: “It’s probably the best value for money sponge&dough- solution of all.” Of course, the mixer and fermentation section can also be encased and air-conditioned if necessary.

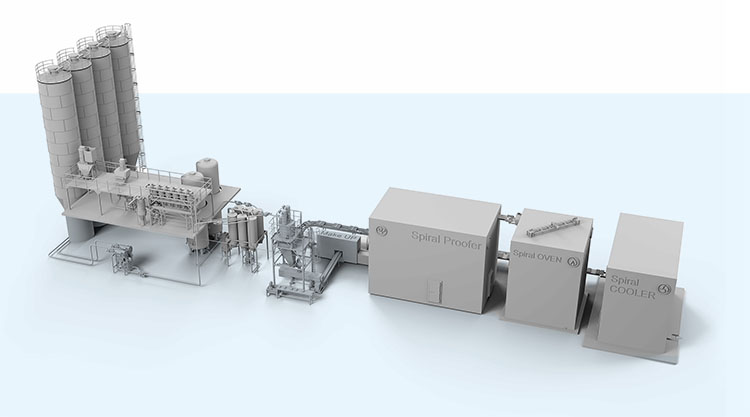

The layout being presented by Zeppelin in Las Vegas is based on a project in cooperation with well-known European manufacturers such as Handtmann, which is supplying the dough divider, and the Tecnopool Group, which is responsible for tray handling, the proofer, oven, cooling system and, if necessary, the freezer.