G/BT GmbH Bakery Technology offers a triple team to gently make up wheat mixed,

rye and gluten-free doughs.

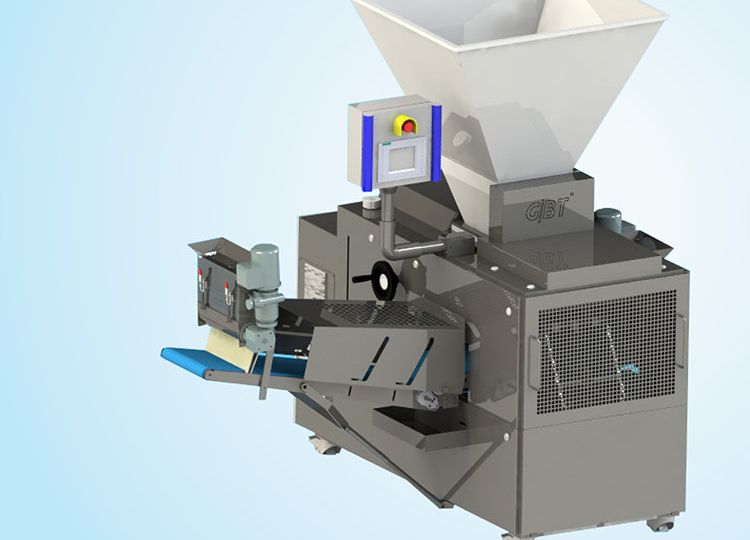

Making good things even better is the claim of G/BT GmbH Bakery Technology (GBT) in Villingen-Schwenningen. The dream team of an Olympia 3000, a Bola 3000 H and an LR6 DW2 B1 has always been a good choice when gentle processing of wheat mixed, rye and gluten-free doughs is involved. First of all, the Olympia 3000 divides the dough. The hygienic design dough divider has undergone further technical optimization. According to the company, the plant processes all dough types gently and with accurate weights. It can even process doughs with a long dough resting time, and dough weights/dough pieces from 150 to 3,000 g are possible. The plant is operated via a touchscreen monitor. The integrated recipe management system allows 99 different recipes to be saved.

Next in line is the BOLA 3000 H belt-driven round molder, which processes doughs from wheat mixed to rye in the weight range from 300 to 2,000 g. Two separate drive motors allow the belt speeds to be controlled separately, which improves the results of molding. The height and angle of the molding channels can be adjusted individually according to the bakery’s requirements and needs. GBT’s BOLA 3000 H belt-driven round molder is designed for a high output capacity of up to 2,500 pieces/hour, depending on the weight, and with a 3,000 mm molding path.

The plant constructor relies on the LR6 DW2 B1 to enable the long-molding of wheat mixed and rye doughs. For this, the machine processes dough weight ranges from 200 to 3,000 g. The integrated pressure-flattening roller pair are adjustable independently of one another. The same holds true for all three plants: when further developing the hygiene design of the trio, the designers attached special value to hygiene and cleaning friendliness, as well as to easy operability and low energy consumption.

Flatbread lines: “The biggest single order” for GBT

GBT Bakery Technology and its sister company GBT Fördertechniksystems (Conveyor Technology Systems) will supply four fully-automatic flatbread production plants to a customer in the Middle East. Each line achieves a capacity of up to 14,000 breads/hour. The company did not state the order value, but Managing Director Wolfgang Fuhst said the conclusion of the contract was “the biggest single order in its 19-year history. According to information from the www.econo.de portal, GBT earned a balance sheet total of around EUR 7 million in 2017.

The contracting partners after the concluding discussion