The importance of dough rheology during processing.

A collaborative project set up between the Australian Export Grains Innovation Centre (AEGIC) and Bake Tran aimed to achieving a greater understanding as to what contributed to the development of dough and could improve process efficiency for the manufacture of bread (Cato and Cauvain, 2019). While the SE Asian bread market was a key focus for the project, from the start it was recognised that the study of dough development through mixing and processing would have wider implications and offer new opportunities for breadmaking throughout the world. At the heart of the Australian Wheat for Asian Baking (AWAB) project was the need to better understand and quantify the relationship between energy input (total and more importantly, rate of delivery), the rheological properties of dough leaving the mixer and its behaviour during processing to the prover, and the influence of key ingredients. A fundamental decision within the AWAB project was that all mixing studies would be carried out with a ‘full’ recipe to make the project outputs more immediately relevant to commercial practice. A Perten doughLab was used to mix the doughs and capture relevant dynamic rheology data with the rheological properties of dough ex-mixer and during processing were assessed using a Warburtons Stickiness Test rig fitted to a Stable Microsystems Texture Analyser.

Principles of the Warburtons Stickiness Test

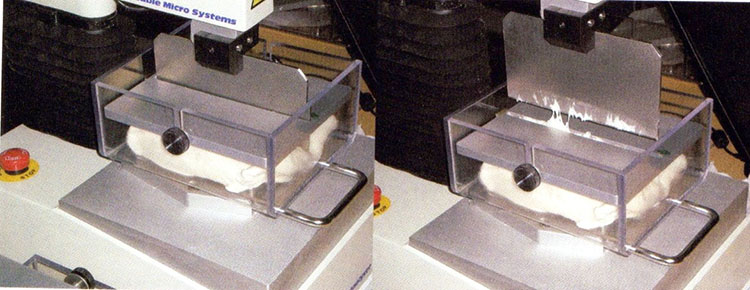

The Warburtons Stickiness Test (WST) rig comprises a Perspex box into which individual dough pieces are placed for testing. Two sizes of box are available; the smaller version accommodates dough pieces in the order of 450-500 g and the larger 900-1,000g. The dimension of the boxes approximate common sizes of dough pieces that would be available after leaving the divider on commercial pan bread lines. The underpinning principle of the WST procedures allows full recipe doughs to be tested with minimum human manipulation of the pieces. Once in the box, a lid with a slot is placed over the dough piece and clamped in place; minimal pressure is applied to the pieces as the lid is fixed. The Texture Analyser is fitted with a knife blade to match the lid slot dimension. The blade is first driven downward though the slot and into the dough under fixed conditions. Upon reaching a pre-set depth, the blade is withdrawn (Figure 1). In one sense the procedure may be likened to that of a commercial divider with the knife blade shearing the dough as it passes through it. As the blade stays in intimate contact with the dough throughout the test there is little opportunity for the rheological properties of the dough to change because of exposure to atmospheric conditions. Temperature control of the test environment is not required as the elapsed time is too short for the temperature of the dough piece being tested to change.

Warburtons Stickiness Test rig

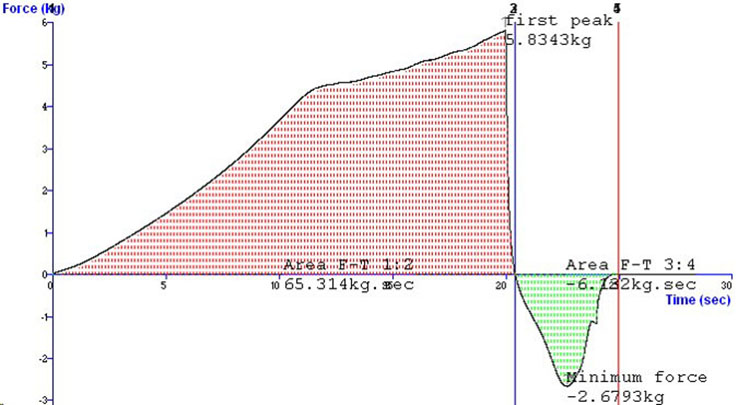

The origins of the WST lie with the concerns in the UK for the potential impacts on dough rheological properties as the result of the programme of salt reduction in bread (Cauvain, 2015). It is known that salt (sodium chloride) affect dough rheology, consistency and crucially, dough stickiness; though it had been hard to measure the later in an objective way. The passage of the blade through the dough with the WST creates a distinctive form of data. During its downward movement, the resistance of the dough to its passage is recorded, while the upwards movement on its withdrawal records the adhesive resistance of the dough. The distinctive form of the graph recorded during the test is illustrated in Figure 2 from which a number of objective measurements may be taken. Key properties include the compression and adhesion peaks, and the compression and adhesion areas (equivalent to the work required to carry out the two components of the test cycle). In broad terms the compression data can be related to dough consistency and development, while the adhesion data can be related to dough stickiness.

Effects of dough processing

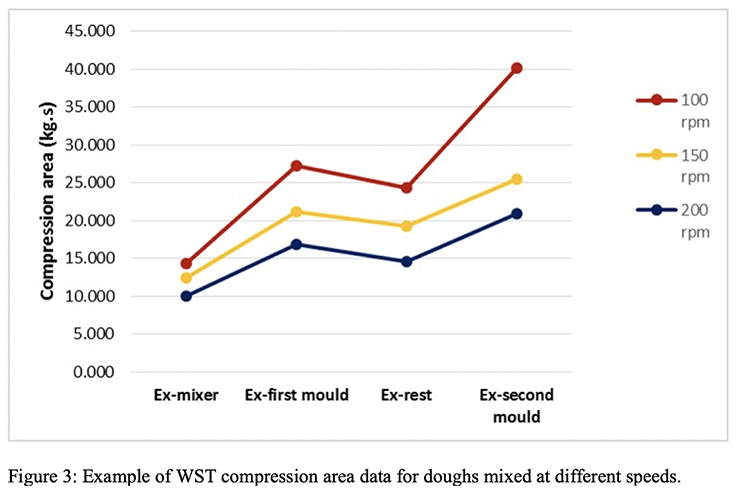

Bakers are well aware that the manipulation of dough during processing induces changes in the rheological properties of the individual dough pieces with moulding steps increasing dough firmness while resting periods between moulding steps lower dough resistance and improve dough extensibility. As the WST is designed to evaluate full recipe dough pieces, it was soon recognised that the progressive changes in dough rheology during processing could be monitored. Not only would it be possible to provide objective data on the impact of individual dough processing operations, but it would be possible to integrate the data so obtained with the impact of ingredient, recipe and process changes introduced during mixing.

An example of the information that can be obtained is shown in Figure 3. In this example, the dough has been mixed at 3 different speeds and the compression areas at different moments in processing are considered. The overall pattern with each of the 3 mixing speeds is similar; namely there is an increase in compression area after the first moulding stage, no significant change as the result of a rest period (6 min for this example) but a further increase after the second (final) moulding stage. The overall pattern of results is consistent with the common expectation of bakers, as noted above, and since there is no change in dough moisture content during processing, the likelihood it that the changes in dough rheology are related to the contribution that dough moulding makes to dough development. Of further interest is that the net change in compression area is less with the dough mixed at the higher of the 3 speeds; an interesting example of the complexity of understanding the relationship between dough mixing and processing.

The impact of recipe changes may also be followed using the WST. The example illustrated in Figure 4 examines the effect of a couple of commonly used improver components; namely ascorbic acid (AA) and fungal alpha-amylase (FAA). When AA is present in the dough recipe, there is an increase in the compression area at all stages; this result is entirely consistent with previously recorded effects of adding AA, that is, the dough become firmer. A small decrease in dough firmness is recorded when FAA is used alone, again something that is often observed when judging dough consistency by hand. The general effect of the moulding stages on dough consistency remains similar to that illustrated in Figure 3.

Graphic output from Warburtons Stickiness Test

Dough stickiness

In many ways the sensory assessment of dough stickiness is linked with the judgement of dough development and has continued to rely on the manipulation of dough in the hands of operators, experienced or otherwise. Judging whether a dough has been correctly (fully) developed is commonly based on determining the ability of a small piece of dough to be stretched to a thin film without it breaking. As is well understood, dough development is poorly defined and represents the composite of several linked properties. While there have been many attempts to define dough development and to relate sensory experiences to objective methods for doing so, less attention has been focussed on dough stickiness. As with dough development, the assessment of stickiness in a commercial bakery relies on operators handling the dough as it leaves the mixer and judging from their experience, whether it can be processed through the plant concerned. A common response to doughs judged to be sticky is to reduce the recipe water level or by the liberal application of ‘dusting flour’ during processing.

As part of our investigations into dough development we evaluated the concept of dough stickiness using both sensory and objective (WST) techniques. The study involved the following recipe and dough process changes:

+ Recipe water levels at -7.5, -5, -2.5, standard, +2.5% and +5%.

+ Dough temperatures ex-mixer at 24, 30, and 36oC.

+ Recipe salt at standard and -50%.

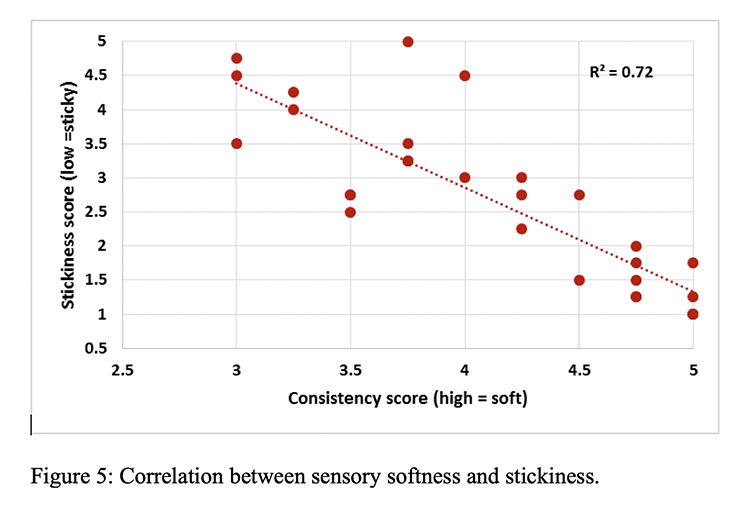

For the sensory assessment, individuals were asked to rate both dough stickiness and softness on independent hedonic scoring scales, along with a judgement as to the ‘processability’ of the dough. Observations made during the sensory assessment quickly revealed that individual assessors interact differently with the dough when they handled it which

resulted in a range of different scores for most of the trial variations. Since each of the sensors largely manipulated in the same manner to make the assessment, this unexpected result was highly individual and immediately raised concerns as to similar judgments by operators in commercial environments. In contrast, the assessment of dough softness was more consistent with less variation between operators.

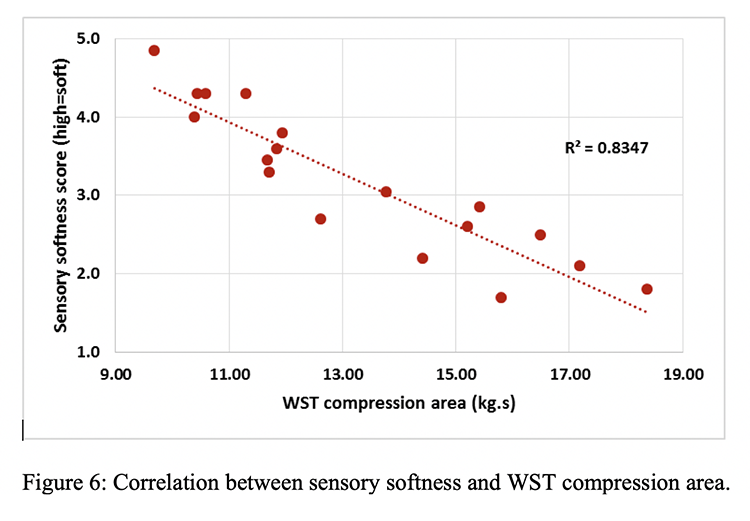

The sensory assessment of dough consistency (softness) and stickiness showed that they were strongly related by individuals (Figure 5); to the extent that it could be concluded that the sensory assessment of the suitability of dough for processing is based on dough softness and stickiness with no apparent discrimination between the two properties. There was a reasonable agreement between sensory and WST assessment of dough softness based on the compression component of the WST test cycle (Figure 6). The relationship between sensory and WST assessment of dough stickiness was not as strong; in part due to fundamental differences in the way the property was assessed and in part, because of the significant variation in individual assessment of dough stickiness.

Impact of processing on dough stickiness

It has long been considered that a contributor to perceived dough stickiness is the impact of the shear forces to which the dough is subjected during mixing and processing. The most common point at which dough stickiness is assessed by operators is at the end of the mixing cycle or during the initial processing (e.g. dividing and rounding), both operations undoubtedly involving significant shear forces. Indeed, if the assessment of dough stickiness is delayed for a short period (20-30 sec) after mixing has finished, the degree of perceived dough stickiness is diminished. Furthermore, gentle manipulation of sticky doughs delivers a significantly less sticky dough.

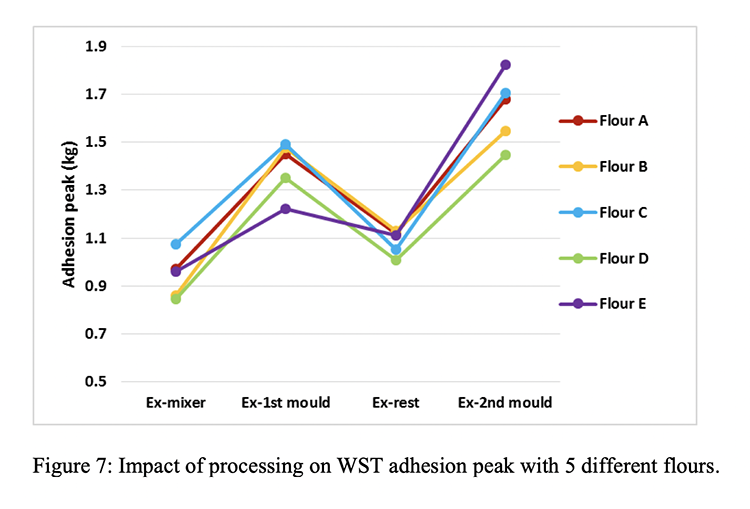

An example of the impact of dough processing is illustrated for 5 different flours in Figure 7; in this case the WST adhesion peak (maximum force) has been used to assess dough stickiness. The results show stickiness increases as a direct result of the first and second moulding stages where the deformation forces required to change the shape of the dough pieces creates high shear of the gluten network. In contrast, when the dough pieces are allowed to rest between first and second moulding stages (6 min in this example), stickiness decreases in line with practical observations in bakeries. The pattern of change in dough stickiness during processing is the same for all the flours tested, though there are small variations in the response of each of the flours to the dough processing regime applied.

The manufacture of bread and other fermented products, whatever the chosen breadmaking process, is based on the complex interactions of ingredients, recipe and process inputs. An understanding of those interactions not only helps us to optimise existing product quality but also to identify opportunities for new and more efficient dough processing methods (Cauvain, 2019). While the development of an appropriate gluten network in the mixer remains a critical factor in determining final bread quality, the relationship between the rheological properties built into the dough during mixing and the manner in which it is processed from bulk to unit portions is critical. Indeed, one might say that dough development starts in the mixer and finishes when the individual dough pieces enter the final prover. Understanding changes in the rheological properties of dough during both mixing and processing are equally important for the future of commercial bread making.

References

+ Cauvain, S.P. and Cato, L. (2019) Australian wheat in the SE Asian bread market: Part I – An Overview. baking+biscuit international (5) f2m food multimedia gmbh, Hamburg, Germany, 18-22

+ Cauvain, S.P. (2015) Technology of breadmaking 3rd edn. Springer AG, Cham, Switzerland.

+ Cauvain, S.P. (2018) Improving the processing of dough to bread. In, The future of baking: Science-Technique-Technology, baking+biscuit international year book, f2m food multimedia gmbh, Hamburg, Germany, 36-41.

Authors: Dr. Larisa Cato and Stanley Cauvain

Stan Cauvain is a Director and co-founder of BakeTran, an international consultancy providing technical services to bakeries, mills, and related ingredient and equipment suppliers. He is particularly active with new process innovation and product development. He has published many technical books and articles on baking and milling technology.

Dr. Larisa Cato is an internationally recognised expert in the field of wheat quality and end-product requirements. As the WHEAT QUALITY TECHNICAL MARKETS MANAGER FOR THE AUSTRALIAN EXPORT GRAINS INNOVATION CENTRE she has been leading the project Australian Wheat for Asian Baking which aims to identify key requirements of wheat quality for bakery products in South East Asia.