Cake Concepts was established in 2012 and was built on lots of experience. CEO Simon Holl had been working in the industry for many years before starting up Cake Concepts.

Today, Cake Concepts, with production facilities in the Amsterdam area of The Netherlands exports 95% of its Funcake and Pancake lines.

Our philosophy is based on, “Combining new technologies and customer demands to get the best and perfect Funcake and Pancake products”, explains Mr Holl. “That’s the driving force behind generating new ideas and innovation. As consumer demands change, new cake products must be healthy and tasty as well as also looking fabulous. And that combination is a challenge for most producers. In our constant drive to get the best for customers, as we love innovation, we do as much research as possible and listen carefully to market signals. We work closely with our customers to find out what they really want. It’s not just about developing and delivering the right machine, as we need to discuss the ingredients, the recipe, the batter and the filling. For example, when considering the recipe, the challenge is to obtain a soft texture and a long shelf life. By considering the product quality first and its shelf life as an optimizer for the supply-chain, we will have a game-changer”.

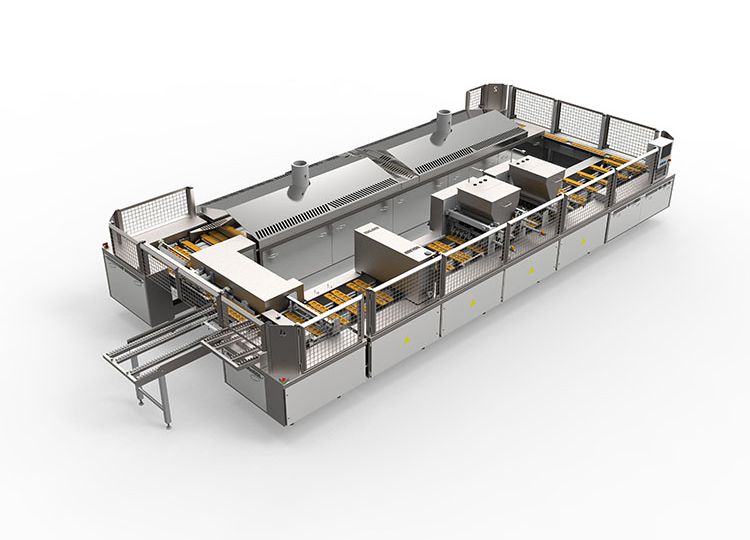

Cake Concepts produces industrial machines, which are unique due to the customization of the design according to the manufacturing requirements and the plant structure. As mentioned, recipes are really important and can affect the machine design. For example, an option is to add the cooling tunnel between the oven and the sandwich unit in the case of pancake production. This will allow for dairy application, even icecream or savory filings. The production capacity for pancakes depends on the product recipe; systems can reach up to 16,000 pcs/hr.

With Cake Concepts, Funcakes of any shape can be created using 3D design tools to produce unique products. At the center of each Funcake, there is a flavorsome and delicious filling – options are unlimited. The 3D design tools allow any form of product to be sculpted using the baking moulds.

The spectacular results are down to proven technology. The mould is closed during baking, allowing leavening agents in the recipe to generate gentle pressure during the process. The pressure pushes the batter outwards, meaning the contours of the mould are followed accurately. This results in a cake with a smooth surface and lots of detail. Every bite of a Funcake is spectacular. This is because the fillings are applied before baking and follow the contours of the mould, allowing a high filling ratio.

“We produce with passion”, according to Mr. Holl “and we aim to deliver the best equipment to companies so that their products are unique to the market. Our equipment makes products that stand out from the ordinary.”