American Pan UK is part of the Bundy Baking Solutions group and is a world leader in providing custom and stock baking tins and trays, proprietary coatings and refurbishment services. It is committed to innovation and to providing products to commercial bakeries for guaranteed long-term performance.

One customer, two challenges, two perfect solutions. By investigating the cause of tray and tin failures and product waste, American Pan UK designed new products that saved one industrial bakery in the UK operating costs and time.

Challenge One

A large bakery plant in the UK was using a Mecatherm oven system with 2,000 x 800 mm sized trays accommodating 22 moulds per tray to produce baguettes and French sticks.

The company found that the coating on the tray it was using was not performing causing products to stick to the moulds resulting in a high percentage of waste (15%) and poor quality products. During the baking process, the baking the trays need to go from the oven to the spiral freezer within 5 minutes and therefore the coating has to be able to withstand heat, cold and condensation. The trays were getting damaged during the process and warping causing line jams and stoppages. In order to repair the trays, the whole line had to be shutdown resulting in long periods of downtime and loss of productivity.

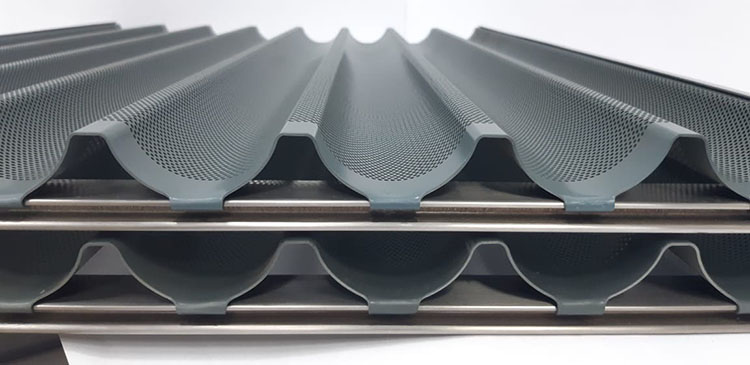

Stacked trays ready for shipment

American Pan Solutions

A new tray design was used with a DuraShield, dark non-stick fluoropolymer coating.

+ Stainless steel frame for more strength and rigidity preventing damage to the frame

+ Corner gussets added to the frame to maintain rigidity and the square shape of the tray, ensuring the tray remains flat during its lifetime

+ Fully sealed frame with a watertight design

+ Tray insert constructed of high strength aluminum alloy that resists warping and retains pocket shape over the life of the tray

+ TabLock design used to replace rivets on the ends of the flutes and preventing product retention on the depanner and allowing for quick and easy screen replacement in the bakery

After Coating

All these enhancements were added to prevent line jams and extend the life of the tray. A fully sealed frame ensures that condensation caused by the blast freezer is kept out of the frame. It is important to note that this design is also good for in-line washing of trays.

Results

The company saw improved efficiencies and reduced running times with waste decreased from 15% to 3% and operating hours be reduced by over 30%. The life of the tray was also doubled with an estimated 4,000 + releases before recoating/replacing of inserts.

3+3 – 6 – on Bread Tin

Bread Tin – Top + Bottom

Bread Tin – Stainless Rod for Strength

Challenge Two

The same large bakery in UK was using a high speed Lanham oven system with a 6 on bread strap set to produce 800 g white and wholemeal bread loaves.

The customer discovered that the bottom of the tins were wearing very quickly resulting in uneven baking and over baking of the bottom of the loaves. Due to wear and other factors, the tin sets were not maintaining their shape and would cause line jams and stoppages. Overall, the tin life was very short and costly.

American Pan Solutions

A new tin set was designed with an AmericoatPlus Glaze coating.

+ Bottom strap was positioned 2 mm below the bottom of the tine for protection of the bottoms through conveying

+ Slight tensioned bow at the bottom of the tins

+ Extra strapping just above the bottom strap to prevent warping of the set and ensure perfect alignment between top and bottom straps

+ 3+3 – 6 strap design to allow proper spacing for the bakery system center guides

+ Stainless steel wire used between 3-tin sets to provide extra strength and rigidity to overall set.

The slightly tensioned bow in the bottom of the tins ensured that when heated the bottoms become flat and provide for a more consistent bake. With the AmericoatPlus Glaze coating the bakery was able to reduce the amount of release oil sprayed on the tins from 2.2 g per cavity to 1.2 g.

Results

With the introduction of the new pans, the issues with pan warping and wear were resolved and a reduced maintenance was required on the system because the pans were not jamming. The life of the pan was more than doubled. This was accompanied by improved product quality and consistency. AmericoatPlus Glaze provides more releases and recoating services can extend the coating life even more. There was a 45% decrease in the amount of oil needed as a release agent, eliminating the build up on conveyors and other equipment as well as improved overall hygiene and safety of plant. With reduced carbon build-up on tins there is reduced risk of product contamination.