Olivier Sergent, President and CEO of the Mecatherm Group, discusses strategy with Baking and Biscuit International’s Dirk Dixon.

Dixon: Since 2014 you have been at the helm of Mecatherm. 2020 has brought about unprecedented challenges for corporations on a global level due to COVID-19. Some would argue that we are in the middle of an existential crisis. How have you adapted, as an individual and as a leader in moving the company forward in this situation?

Sergent: The COVID-19 crisis has had an impact on both our staff and our customers, the two pillars on which our company is based. For our staff, it was a full-scale crash test, which impacted on each individual, their professional activities (home-office, management), the company’s processes and the industrial activity with also some supply chain difficulties. Our governance bodies have enabled us to get through this stage while preserving the health of each individual and strengthening our managerial models.

As for our clients, they have been affected to varying degrees depending on their typology. Those who market their fresh packaged products to supermarkets were less affected than those selling their products to hotels and restaurants, for example. However, it is difficult to conclude on structural impacts.

Today, our major concerns are first and foremost to preserve the health of our employees, to ensure our customers’ production capacity by maintaining our after-sales service, and to continue to work as much as possible internally to be ready for the recovery.

As an individual, I have been able to measure the importance of a strong and supportive executive committee and shareholders.

Dixon: Prediction is often blinded by fact. Optimism is a mindset crucial for survival. How will the baking industry change? What will happen to the artisan bakers and what will happen to the industry?

Sergent: Many prospective studies have appeared, but today it is too early to pretend to draw structural conclusions. Nevertheless, consumers around the world are still driven by two main drivers: The first is to have good quality reference products or basic products available at the lowest prices. The second, depending on the situation, is to have products richer in “storytelling” (everyone putting what he wants under this concept: gluten free, organic, fancy, gourmet, local, ethical, etc.) This modern segmentation is permanent and will not be affected by the crisis.

One can imagine that in certain categories of the population in a situation of economic stress, the demand for the first increases. So that this demand is not frustrating for the consumer, the pressure will remain permanent to improve the quality of basic products.

Also that again, the trend existing in recent years, set up by industrialists, will continue with the coexistence of central units of massive production of basic products and a finer territorial network with units of average capacities and a great flexibility to serve storytelling products. Artisans and industrialists will, of course, continue to co-exist in this scenery to respond to local demands as closely as possible.

Dixon: We have seen Mecatherm move forward in a very positive manner since you have taken over. In the light of this, how important is the saying, “A company is only as good as the people it employs”?

Sergent: In the life of every company, there are periods of change in management models and the company must constantly reinvent itself by building on the successes of its history. The challenge has been to build a team that brings together in a balanced way the historic talents that have built the company over the past decades, and new talents from very different horizons and industries to bring a new perspective on the way the company is run.

It has also been an opportunity to welcome many representatives of the new generation to the company. It is a permanent job, never finished, but we are doing our utmost to make Mecatherm a company that attracts talents, retains them and makes them grow.

Dixon: What milestones has Mecatherm achieved over the last few years?

Sergent: Historically, Mecatherm’s success has been built around the baguette. In recent years, we have significantly expanded our geographical coverage of customers and the range of finished products that we address with innovative technical solutions, without forgetting, however, to constantly improve our historical product.

In addition, we have integrated two major constraints into Mecatherm’s entire value chain: on the one hand, we offer equipment and production lines that continuously improve the quality of finished products whilst on the other hand we have a very important focus on industrial performance throughout the entire life cycle of the equipment (projects, start-ups, ramp-up support) and a very wide range of services that starts from the spare part and goes all the way to the application of digital techniques to help our equipment operate.

This approach has found its full expression in the products we recently launched for dividing, mechanization and baking of products from the Bakery-Viennoiserie-Pâtisserie sector.

Dixon: You recently held webinars on the topic of ‘Clean Label’. What did these discussions focus on and what has been the feedback from the bakers?

Sergent: Thank you for mentioning this. This approach is in line with Mecatherm’s firmly stated desire to integrate the profession of industrial bakers into its activity: to not only meet their customers’ expectations regarding the finished product, but also to understand the industrial subjects they live with every day.

The Clean Label is one of the elements of the “storytelling” products that we are all looking for as consumers. Its production has strong implications of course on the choice of ingredients, but also on the production process. This is why we brought together ingredient manufacturers, mixer manufacturers, packaging manufacturers and scientists for this seminar.

Dixon: How difficult is it to adapt to the increasing demand for Clean Label products from a manufacturing standpoint?

Sergent: The real question is why do people insert different ingredients in the basic ingredients to improve the final product? It is because it makes it easier to process otherwise they wouldn’t put in these ingredients that are expensive and not really complying with the E free trend, so if they are adding ingredients it’s to make the production easier. What I mean by making the production easier is that it starts with mixing and it’s very important in the makeup area where the rheological aspect of the dough can be improved by adding ingredients and if you have a good way of handling the dough you can make it without adding ingredients – as well during the proofing and conveying some ingredients strengthen the structure of the dough so it can support the shocks much better. If you have a good way of handling the product then you can do it without adding specific ingredients. During the baking process, if your oven has a lack of power on the bottom, the product will not rise in the oven and so if you add some ingredients it will help the development. If you have a good oven then you don’t need these ingredients to reach the same development. So, I would say stage by stage and at each step of the production of a product you can focus on how each step is done and you can remove ingredients step by step if you have the right technical solutions.

Dixon: What trends are you seeing at present with regards to consumer demand?

Sergent: As I said in my introduction, I do not see any fundamental changes in the trends already identified in previous years, but rather an acceleration. Nevertheless, beyond the product itself, additional constraints will emerge concerning packaging, reshaping at the point of sale and traceability requirements for development. Of course, the tremendous evolution of e-commerce will certainly ensure distribution evolves.

It seems to me that at the end of a phase as traumatic as the one we have just gone through with COVID-19, the transparency that was already requested will no longer be enough, but trust will become a differentiating factor. Trust that will have to be applied to all the stakeholders in the value chain: from the field to the plate.

Mecatherm has organized four webinars related to the “clean label” / “free from” topic.

WEBINAR 1

Why go to Clean Label in the baking industry?

To see the movie on youtube click the picture.

WEBINAR 2

Division and moulding challenges of Clean Label products

To see the movie on youtube click the picture.

WEBINAR 3

Baking Clean Label products

To see the movie on youtube click the picture.

WEBINAR 4

Production line solutions for Clean Label products

To see the movie on youtube click the picture.

Dixon: What challenges do your customers face now and in the future?

Sergent: When investing in a new production line that represents several millions of investment, it is necessary to have a clear vision on a large number of parameters: How will the consumer evolve? How will the distribution channels evolve (explosion of e-commerce)? What financial security can suppliers bring?

All these topics are under stress today, which makes investment decisions sometimes complicated for our clients. The answers that we can provide as a supplier are of course based on the flexibility and scalability of our equipment, as well as on the guarantees of our company’s durability.

Dixon: What projects are you currently working on for 2020?

Sergent: This crisis has separated us physically from our customers, even if we have done everything to stay close to them. This has nevertheless highlighted the importance and the value that digital techniques can bring, not for management operations, with which manufacturers are already well equipped with, but for business tools for the people who operate, maintain, adjust and clean the lines. This field strategy, which aims to talk to people who live with our equipment during the day, night and weekends, seems essential to us and is perfectly in line with our values of putting people at the heart of our business and our mission to simplify their lives.

Dixon: During the last IBA you presented the M-TA oven. How has this system been received by your customers? Can you tell us about any particular installations?

Sergent: The success of this oven has been beyond our expectations. It has been awarded at IBA 2018 in Munich, then at IBIE Las Vegas and nominated at Gulfood Manufacturing Dubai in 2019.

This oven perfectly supports our strategy of flexible lines without any compromise on the quality of the most challenging products. The line flexibility is often synonymous with complex control and long changeover times. All the solutions we develop in software and hardware tend to positively address these challenges. The successes in North America, Europe, Russia and Africa confirm us in this direction.

The first M-TA oven installed after IBA 2018 was at the Ultrapharm plant in Poland (Finsbury Group) to produce tin bread and other gluten-free products. To date, the customer is fully satisfied with his equipment.

Dixon: The Baguette factory was a project that you launched in 2017. How important is this turnkey business for Mecatherm and how will it develop?

Sergent: While initial achievements have been successful, projects in preparation take a long time in countries where heavy investment decisions are subject to even more scrutiny than in more developed countries. Nevertheless, the strong social demand for basic products

guaranteeing excellent food security and low prices is confirmed.

Dixon: Mecatherm has been synonymous with baguettes and their production. You have made a shift to bagels?

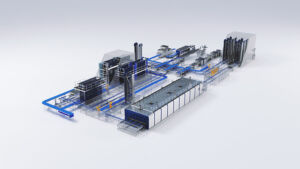

Sergent: This corresponds to our strategic approach. Depending on where you go in the world, people are expecting turnkey solutions for a single product. Our offer is spread into two ranges and we have dedicated production lines for specific products. We have the MecaBaguette line which is a historical product of Mecatherm, but we also have the MecaRusk line which is a standard line for rusks. We now have a standard line for bagels after having worked closely with a key player in the bagel make up line, ABI Ltd, and we have made a committed approach into how to create the best bagel on a very standard line economically whilst producing the best possible product. So, this is one approach and we have also developed the MecaFlex which is a very flexible baking system where you can connect a wide range of modules allowing

customers the opportunity to enrich their lines as their business grows. You can feed this with a wide range of baking trays or tins. It is a very flexible line that is not dedicated to a specific product. As I have already mentioned, I believe that the industry will spread with two kinds of installations; one that has high output for a standard product, and for smaller entities and regions a smaller but more flexible line.

Dixon: What is the synergy like with ABI?

Sergent: Excellent. They are world leaders in the make-up lines and we work very much with them; not only for the makeup line but because they have a deep understanding and know-how when it comes to producing bagels. They explained to us what our ovens should look like, how the boiling and seeding aspects work and how to cool and to freeze; so many different things. So yes, our co-operation with them is excellent.

Dixon: Can we expect to see some exciting new innovations from Mecatherm for IBA 2021?

Sergent: Yes, you can, let’s meet at IBA 2021!

All I can say is that it will be the continuity of the path traced for a few years, and always oriented on product quality and industrial performance.

Dixon: Thank you for the interview, Monsieur Sergent.