Although eating habits are tending to be more similar throughout the world, differences, originating in local traditions, still remain from one continent to the next. In the world of bread and baking, this is also the same.

Finished products such as sandwich bread, croissants and other types of Viennese pastries can be found in abundance on the shelves, alongside more and more diverse baked goods such as biscuits, filled pastries and sponge cakes.

These are very diversified products in terms of texture that require specific attention in the mixing process. It goes without saying that dough that contains fat, and dough that doesn’t, is not mixed in the same way, and the same is true when the dough contains inclusions (chocolate chips, blueberries, etc.), which are more difficult to mix. VMI has adapted and developed a “snacking” version of its vertical double tool mixer, the KNEADSTER, that fully meets these requirements. With its specific tooling and its reverse rotation, all types of dough and meats/vegetables can be mixed.

At the heart of VMI’s machine development is a desire to be even more cost-effective and environmentally responsible, and so an added feature on the KNEADSTER mixer is the ability to store the energy produced by the rotation of the bowl and reinject this energy back into the tools’ driving system, thus significantly reducing energy consumption (up to a saving of 15%). VMI has vast experience in designing planetary mixers and dough or batter-mixing systems for the snacking, pastry and confectionery industries. To date, about 30,000 planetary machines in total have been manufactured and installed worldwide by VMI.

Planetary Mixer

There is a wide variety of planetary machines including lines for both small and medium-sized companies, as well as fully automatic solutions designed for wholesale baking and food industries.

The range of small planetary machines has capacities of 20, 40, 60 and 80 liters. All are equipped with a choice of 5 speeds, inverters, recipe programming, and 3 different attachments. (Please see photographs on Page 15) The speed of rotation of the kneading tool and the planetary mechanism can be adjusted. Up to 20 different phases can be programmed for each recipe, all designed for better consistency in mixing.

The design of the mixers is such that they are easy to clean. The area in contact with the product is almost completely devoid of seams and joints where the product could accumulate, creating a negative microbiological background. The working area is illuminated and equipped with a safety grid with a transparent, easily removable screen and a closing chute for loading the ingredients during mixing. The area of the flat planetary mechanism is easily and quickly cleaned. The whisk has removable rods, which are easily replaced in case of breakage and give the best product volume. The carriage stroke allows the replacement of tools without removing the bowl. Removable scrapers for the bowl are available as an option.

The kneading bowl on the line of industrial planetary machines is normally lifted hydraulically. These machines have 80, 100- and 150-liter bowls. The machine is designed for a long working life even in the most extreme conditions. 5 attachment points fix the bowl with the frame being pressure welded and mounted on stainless steel supports. The attachment of the tool shaft to the shaft is equipped with an anti-blocking system. It is possible for the machines to be made partly or completely from stainless steel. The programming of recipes and control management help to achieve productivity and consistency goals.

The ULTIMIX planetary mixer is entirely made of stainless steel (304L / 316L). The flat cover is designed without dead zones, which makes cleaning this part of the machine much easier. The bowl lifting mechanism is almost completely hidden in the columns, and the slider guides of the bowl trolley are covered on the outside with shifting straps, which prevents dirt from getting inside the mechanism. The ULTIMIX line uses a patented ultra-flat gearbox, which significantly reduces the height of the machines. Built-in devices for connecting positive pressure/ vacuum supply devices, as well as vertical feed lines for ingredients also reduce the size of machines.

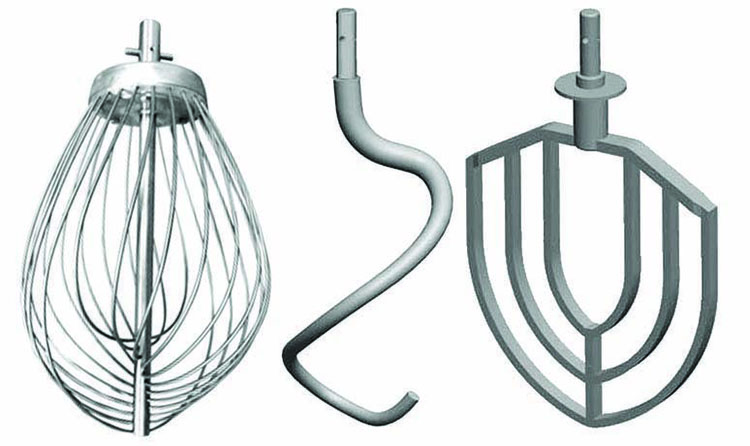

VMI offers a wide range of tools adapted to different viscosities and products, from whipping for sponge cakes to incorporation and homogenization of butter and micro-

ingredients for brownies. The ability to interchange tools very easily makes VMI’s latest planetary bridge mixer, the ULTIMIX, a particularly flexible and adaptable machine. The design of the tools is very important for the efficiency of any mix. For some products, the bowl profile can also be adapted to improve performance.

The VMI ULTIMIX mixer can operate 24 hours a day and can include the automatic integration of ingredients, and in some cases can further optimize the diversity of recipes, while limiting downtime in production. It is an industrial machine that can integrate automatic mixing cycles and be integrated into an automated bowl transport system. Adjusting the ratio of the speed of rotation of the tool around its axis and the movement of the planetary mechanism makes it possible to expose the optimal trajectory of movement of the tool inside the bowl. The control system allows variation in energy consumption. A scraper carfully processes the entire inner surface of the bowl, and at the same time contributes to a better homogenization of the mixture. The scraper and kneading mixing tools are installed on the machine with the help of special devices for quick installation and removal of tools. Several sets of tools are offered as standard.

At the request of the customer, machines can be equipped with a variety of options: supply of pressure over 0.5 bar; ratio variation between speeds of tool rotation and planetary revolution speed; bowl with thermal insulation and the ability to control the temperature; automatic setting of the required temperature with visual display of the process on a dashboard; wireless temperature sensors; a set of pumps with nozzles for the automatic washing device; special drain valve in the bowl for manual or automatic emptying; devices for quick connection of the bowl with heating or cooling fluid supply systems; inspection hatches, vertical supply pipes for ingredients, etc. The machines are supplied with bowl sizes of 200 – 300 – 450 – 600 – 900 liters. At the request of the customer it is possible to create automatic lines based on this line of machines.

Pastry and biscuit batter or dough, can also be produced on kneading machines equipped with a quick tool release system and exchangeable tools of various configurations.

A feature of the snacking version of the vertical mixer SPI AV is both direct and reverse rotation of the kneading tools. An important role in the kneading process is played by the scraper. The machine can prepare both liquid (muffins) and very solid types of dough without any non-mixed parts and dead zones. It easily mixes 10-kilogram blocks of butter or margarine. At the same time, thanks to the special form of the kneading tools, the incorporation of various fragile components into the dough, such as chocolate drops, for example, occurs very carefully, without smearing. The machine is made of stainless steel. All options, except automatic dosing connections are included in the basic package.